Introduction

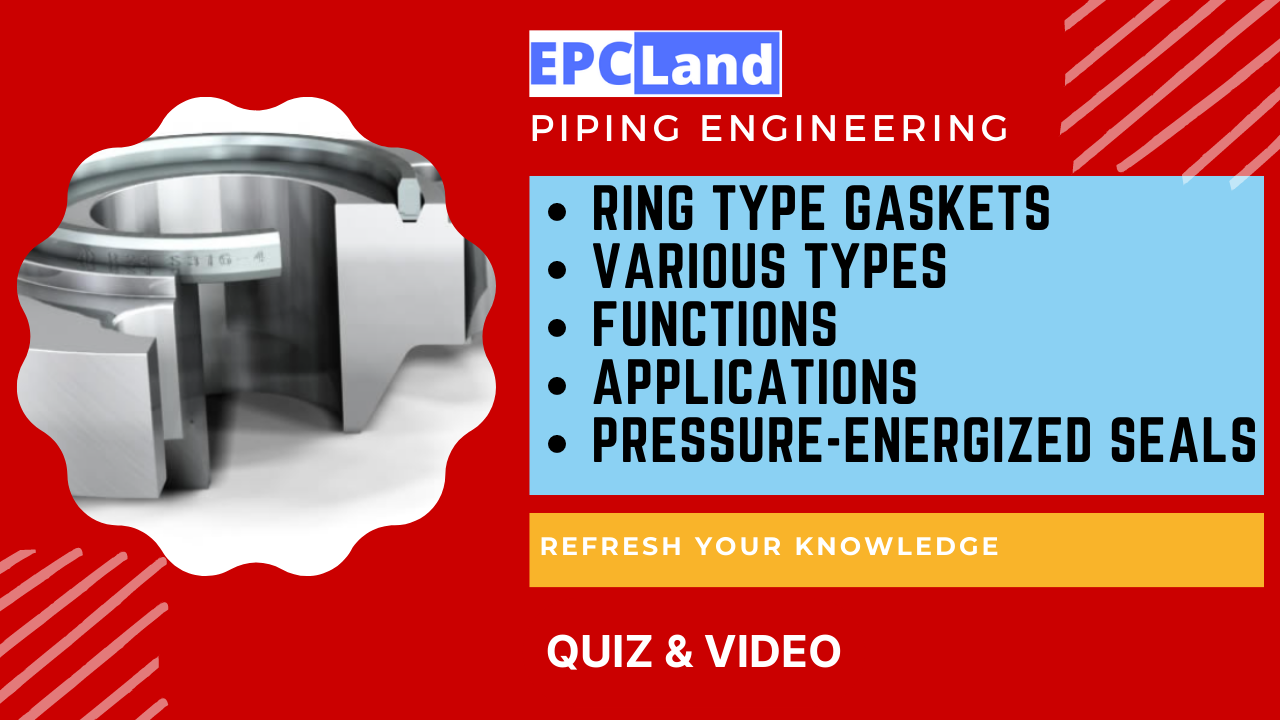

Ring type gaskets are critical components in industrial applications where creating a secure and leak-free seal is essential. These gaskets, commonly known as RTJs, are widely used in various industries due to their exceptional sealing properties. This comprehensive guide will delve into what ring type gaskets are, their types, functions, applications, and the concept of pressure-energized seals.

Table of Contents

What are Ring Type Gaskets?

Ring type gaskets, or RTJs, are specialized seals designed to fit into flanged joints. They are typically used in applications involving high pressure, high temperature, or corrosive environments. RTJs are circular in shape with a cross-section resembling an octagon or rectangle. These gaskets are commonly used in industries such as oil and gas, petrochemical, chemical processing, and power generation.

Types of Ring Type Gaskets

Ring type gaskets come in various materials and configurations to suit different application requirements. Here are some common types:

1. Octagonal RTJs

Octagonal RTJs are known for their high-pressure sealing capability. They have a cross-sectional shape resembling an octagon and are suitable for applications with high flange pressures.

2. Oval RTJs

Oval RTJs are designed for applications with moderate pressures. They have a rounded cross-sectional shape that provides effective sealing while accommodating some flange misalignment.

3. RX RTJs

RX RTJs are designed for pressures higher than those suitable for octagonal and oval gaskets. They have a modified oval shape that enhances the seal’s performance under extreme conditions.

Functions of Ring Type Gaskets

Ring type gaskets serve several key functions in industrial settings:

1. Sealing

The primary function of a ring type gasket is to create a reliable seal between two flange faces. The gasket fills the irregularities and imperfections on the flange surfaces, preventing leakage of fluids or gases.

2. Pressure Resistance

Ring type gaskets are engineered to withstand high pressures, making them essential for applications involving pressurized fluids or gases.

3. Temperature Resistance

These gaskets are capable of withstanding extreme temperatures, making them suitable for applications that involve high-temperature processes.

4. Corrosion Resistance

Ring type gaskets can be manufactured from various materials, including corrosion-resistant alloys, ensuring they can withstand corrosive environments.

Various Applications of Ring Type Gaskets

Ring type gaskets find application in a wide range of industries and scenarios:

1. Oil and Gas Industry

In the oil and gas sector, ring type gaskets are used in pipelines, flange connections, and valves to ensure a reliable and leak-free flow of fluids.

2. Petrochemical Industry

Ring type gaskets are vital in petrochemical plants where hazardous chemicals and high pressures are involved.

3. Power Generation

In power plants, these gaskets are used in steam and gas turbines, as well as heat exchangers, to prevent leaks that could compromise efficiency.

4. Chemical Processing

Ring type gaskets are employed in chemical processing plants to maintain the integrity of the equipment and prevent leaks that could lead to hazardous situations.

5. Marine Industry

In maritime applications, these gaskets are used in ship engines and other systems to ensure the reliable operation of vessels.

What are Pressure-Energized Seals?

Pressure-energized seals, also known as pressure-energized gaskets, are a type of gasket that relies on the pressure within the system to enhance their sealing capability. These seals are commonly used in high-pressure environments where traditional gaskets might not provide adequate sealing.

Pressure-energized seals work by utilizing the internal pressure of the system to exert force on the seal, enhancing its contact with the sealing surfaces. This increased contact pressure improves the sealing performance, making these seals suitable for applications with fluctuating pressures or where maintaining a tight seal is critical.

FAQs

Q1: What is the purpose of a ring type gasket? A1: Ring type gaskets are used to create a secure and leak-free seal between flange faces in applications involving high pressure, high temperature, or corrosive environments.

Q2: What are the different types of ring type gaskets? A2: There are various types of ring type gaskets, including octagonal, oval, and RX gaskets, each designed for specific pressure and application requirements.

Q3: Where are ring type gaskets commonly used? A3: Ring type gaskets are used in industries such as oil and gas, petrochemical, power generation, chemical processing, and marine applications.

Q4: What are pressure-energized seals? A4: Pressure-energized seals are gaskets that utilize the internal pressure of a system to enhance their sealing capability, making them suitable for high-pressure environments.

Q5: What advantages do pressure-energized seals offer? A5: Pressure-energized seals provide enhanced sealing performance under fluctuating pressures, ensuring a tighter and more reliable seal in critical applications.

In conclusion, ring type gaskets play a crucial role in ensuring the integrity and efficiency of industrial systems by providing reliable sealing solutions. With their diverse types, functions, and applications, these gaskets contribute significantly to industries where secure sealing is paramount. Moreover, pressure-energized seals offer an innovative approach to sealing in high-pressure scenarios, further enhancing the reliability and performance of critical systems.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What are Ring Type Gaskets?

Explanation: Ring Type Gaskets are sealing devices used to prevent fluid leakage between pipe flanges, providing a reliable seal under compression.

Question 2:

What are the Types of Ring Type Gaskets?

Explanation: The types of Ring Type Gaskets include Soft and Hard gaskets, Metal-jacketed gaskets, and Corrugated gaskets, each designed for specific applications and sealing requirements.

Question 3:

What are the Functions of Ring Type Gaskets?

Explanation: The primary function of Ring Type Gaskets is to seal against fluid leakage and prevent damage to flange faces, ensuring a tight and reliable connection between pipe flanges.

Question 4:

What are Various Applications of Ring Type Gaskets?

Explanation: Ring Type Gaskets find applications in industries such as oil and gas, chemical, and petrochemical, where they are used to create reliable seals in pipe flange connections.

Question 5:

What are Pressure-Energized Seals?

Explanation: Pressure-Energized Seals are seals that utilize the energy from fluid pressure to enhance the sealing effect, ensuring a tight and reliable seal even under varying conditions.