1. Common Type of Heat Exchanger

What is the most common type of heat exchanger that consists of a bundle of tubes enclosed in a shell?

Explanation: The most common type of heat exchanger that consists of a bundle of tubes enclosed in a shell is the Shell and Tube Heat Exchanger.

2. Plate Heat Exchanger

Which type of heat exchanger is made up of a series of thin plates stacked together?

Explanation: Plate heat exchangers are made up of a series of thin plates stacked together.

3. Process Duty – Sensible Heat Exchange

What is the most common type of heat exchange involving the transfer of heat between two fluids without a change in phase?

Explanation: Sensible heat exchange is the most common type involving the transfer of heat between two fluids without a change in phase.

4. Heat Exchanger Layout Consideration

Why should provision be made for the thermal expansion of heat exchangers in their layout?

Explanation: Provision should be made for the thermal expansion of heat exchangers to prevent issues related to thermal expansion.

5. Heat Exchanger Application Image

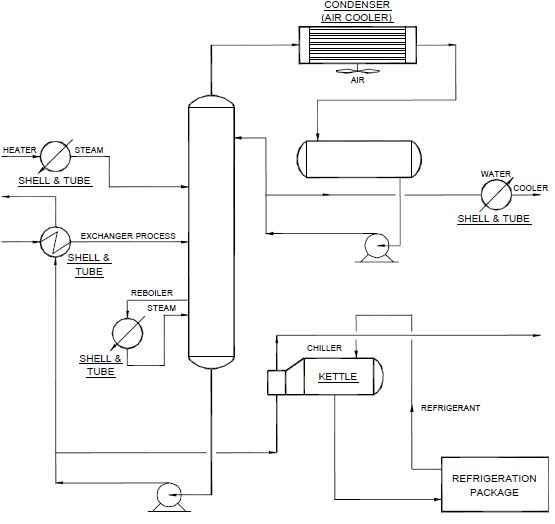

Which type of heat exchanger is depicted in the provided image?

Explanation: The image depicts a Shell and Tube Heat Exchanger.

6. Layout Consideration – Piping

Why should heat exchanger piping be as direct and simple as possible?

Explanation: Heat exchanger piping should be as direct and simple as possible to enhance efficiency and simplify maintenance.

7. Heat Exchanger Type – Air Cooler

What type of heat exchanger is depicted in the provided image?

Explanation: The image depicts an Air Cooler.

Short Article on Introduction to Heat Exchangers

Introduction to Heat Exchangers

Heat exchangers are widely used equipment in the chemical, petrochemical, and refinery industries. They are used to transfer heat from one fluid to another. This can be done by direct contact between the two fluids, or by indirect contact through a solid wall.

There are many different types of heat exchangers, but some of the most common are:

- Shell and tube heat exchangers: These are the most common type of heat exchanger. They consist of a bundle of tubes that are enclosed in a shell. The hot fluid flows through the tubes, and the cold fluid flows around the tubes.

- Plate heat exchangers: These are made up of a series of thin plates that are stacked together. The hot fluid flows between the plates, and the cold fluid flows on the other side of the plates.

- Air coolers: These use air to cool a fluid. They consist of a bundle of tubes that are finned to increase the surface area. Air is blown over the fins to cool the fluid.

- Coil heat exchangers: These are made up of a coil of tubing that is wrapped around a tank or vessel. The hot fluid flows through the coil, and the cold fluid surrounds the coil.

The type of heat exchanger that is used depends on the specific application. Some factors that are considered when selecting a heat exchanger include:

- The fluids that are being exchanged

- The temperature difference between the fluids

- The flow rate of the fluids

- The pressure of the fluids

- The cost of the heat exchanger

Process Duties of Heat Exchangers

Heat exchangers are used for a variety of process duties, including:

- Sensible heat exchange: This is the most common type of heat exchange. It involves the transfer of heat between two fluids without a change in phase.

- Condensation: This is the process of converting a vapor into a liquid by cooling it.

- Vaporization: This is the process of converting a liquid into a vapor by heating it.

- Sublimation: This is the process of converting a solid directly into a vapor without passing through the liquid phase.

Layout Considerations for Heat Exchangers

The layout of heat exchangers can have a significant impact on their performance and efficiency. Some factors that are considered when laying out heat exchangers include:

- Access: Adequate space should be provided around heat exchangers for access for maintenance and inspection.

- Aesthetics: Heat exchangers should be arranged in a way that is aesthetically pleasing.

- Thermal expansion: Provision should be made for the thermal expansion of heat exchangers.

- Piping: Heat exchanger piping should be as direct and simple as possible.

- Mounting: Heat exchangers can be mounted on structures, process columns, or other equipment. Special arrangements should be made for maintenance and tube cleaning in these cases.

By following these guidelines, you can ensure that your heat exchangers are operating efficiently and safely.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.