1. Introduction

Eccentric butterfly valves have emerged as pivotal components in industrial fluid control systems. These valves, with their innovative design and versatile functionality, have become indispensable in various industries such as water treatment, oil and gas, HVAC systems, and food processing. This article delves into the intricacies of eccentric butterfly valves, exploring their evolution, working principles, types, applications, advantages, and associated standards.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

2. Brief History

Butterfly valves have a rich history dating back to ancient times, where rudimentary forms of these valves were used for controlling water flow in aqueducts. However, it was in the 20th century that significant advancements led to the development of eccentric butterfly valves. Technological innovations and materials engineering played a vital role in enhancing their performance and reliability, making them a preferred choice in modern industrial applications.

3. Basic Function and Working Principle

Eccentric butterfly valves operate on a simple yet effective principle. The valve consists of a flat circular disc, mounted on a rotating shaft. When the valve is in the closed position, the disc completely blocks the flow, ensuring a tight shut-off. To open the valve, the disc rotates a quarter turn, allowing fluid to pass through. The offset design of eccentric butterfly valves ensures minimal friction during operation, resulting in quick and efficient control of flow rates.

4. Main Components & Their Functions

4.1 Disc

The disc, typically made of metal or a durable composite material, is the key component responsible for regulating the flow. Its shape and placement determine the efficiency of the valve in controlling the fluid stream.

4.2 Stem

The stem connects the actuator to the disc, facilitating the rotational movement required for opening and closing the valve. Precision engineering of the stem is crucial to ensure smooth operation and prevent leakage.

4.3 Seat

The seat forms a tight seal around the disc perimeter when the valve is closed, preventing any leakage. Materials with excellent wear and corrosion resistance are utilized for the seat to enhance the valve’s durability.

4.4 Actuator

The actuator serves as the driving force behind the valve’s movement. It can be manual, electric, pneumatic, or hydraulic, allowing for remote and automated operation. Actuators provide precise control, making these valves suitable for a wide range of applications.

5. Types of Eccentric Butterfly Valves

5.1 Concentric vs. Eccentric Designs

Concentric butterfly valves have the stem in the center, whereas eccentric valves have the stem offset from the centerline. Eccentric designs reduce wear on the seat, enhancing the valve’s longevity.

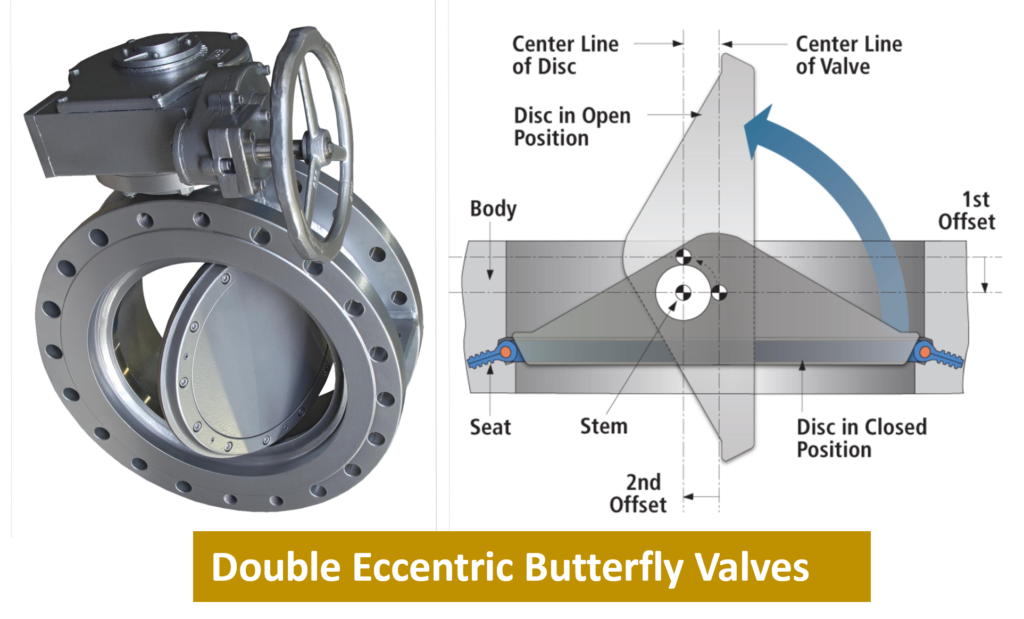

5.2 Offset and Double Offset Configurations

Offset and double offset refer to the eccentricity of the stem concerning the centerline of the valve. Double offset designs offer superior sealing performance, making them ideal for applications where a tight shut-off is crucial.

5.3 High-Performance and Resilient Seated Variants

High-performance eccentric butterfly valves are engineered to handle high-pressure and high-temperature conditions, ensuring reliable operation in challenging environments. Resilient seated valves feature elastomer seats, providing excellent sealing and durability, especially in low-pressure applications.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

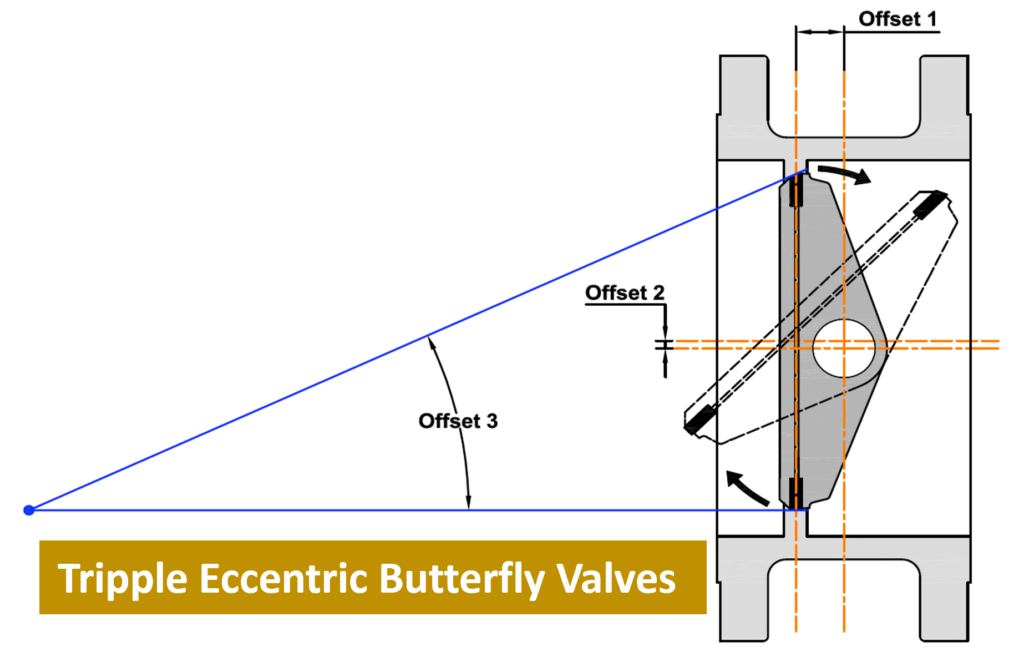

6. Double Eccentric vs Tripple Eccentric Butterfly Valves

| Aspect | Double Eccentric Butterfly Valve | Triple Eccentric Butterfly Valve |

|---|---|---|

| Number of Offsets | Two offsets – stem and disc offsets | Three offsets – stem, disc, and seat offsets |

| Sealing Performance | Good sealing performance due to two offsets | Excellent sealing performance due to three offsets |

| Shut-Off Capability | Limited in high-pressure applications | Superior shut-off capability, suitable for high-pressure systems |

| Friction and Wear | Moderate friction and wear, longer lifespan | Reduced friction and wear, extended lifespan |

| Applications | Suitable for general applications | Ideal for critical applications such as high-pressure pipelines |

| Torque Requirement | Moderate torque requirement for operation | Higher torque requirement due to the triple offset design |

| Price | Relatively lower cost | Higher cost due to the complexity of the design |

| Maintenance | Requires regular maintenance and inspections | Requires less frequent maintenance due to superior design |

7. Applications of Eccentric Butterfly Valves

Eccentric butterfly valves find diverse applications across various industries:

7.1 Water and Wastewater Treatment Plants

In water treatment facilities, these valves are used for regulating the flow of water, chemicals, and sludge. Their quick response and precise control are invaluable for maintaining efficient processes.

7.2 Oil and Gas Industry

Eccentric butterfly valves play a vital role in the oil and gas sector, controlling the flow of crude oil, natural gas, and refined products. Their robust construction and ability to handle high pressures make them essential in pipelines and refineries.

7.3 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on these valves to regulate the flow of air and water within buildings. Their compact size and cost-effectiveness make them popular choices in HVAC applications.

7.4 Pharmaceutical and Food Processing

In industries where hygiene and precision are paramount, eccentric butterfly valves are used for controlling the flow of pharmaceuticals, food products, and chemicals. Their smooth operation and easy maintenance contribute to the efficiency of these processes.

8. Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Cost-Effectiveness | Limited in High-Pressure Systems |

| Low Maintenance | Sensitivity to Contaminants |

| Quick Operation | Potential for Cavitation |

| Space Efficiency | |

| Versatility in Applications |

Eccentric butterfly valves offer significant advantages, including cost-effectiveness, low maintenance requirements, quick operation, space efficiency, and versatility in various applications. However, they have limitations in high-pressure systems and can be sensitive to contaminants, potentially leading to cavitation issues.

9. Associated Codes & Standards

| Standard | Description |

|---|---|

| ANSI/ASME B16.34 | Standard for valves, flanges, fittings, and gaskets |

| API 609 | Standard for butterfly valves |

| ISO 10631 | Standard for industrial valves – Butterfly valves with metallic seats |

| MSS SP-67 | Standard for butterfly valves |

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

These standards ensure the quality, performance, and compatibility of eccentric butterfly valves in various industrial settings. Adhering to these standards guarantees the valves’ reliability and safety in operation.

10. Conclusion

Eccentric butterfly valves have undoubtedly revolutionized flow control in diverse industries. Their simplicity, efficiency, and adaptability make them indispensable components in fluid handling systems. As technology continues to advance, these valves are expected to evolve further, addressing current challenges and expanding their applications. By understanding their design, functionality, and applications, industries can harness the full potential of eccentric butterfly valves, ensuring seamless and reliable fluid control processes.

FAQs

1. What is the main advantage of using an eccentric butterfly valve over other types of valves?

- Eccentric butterfly valves offer a significant advantage in terms of quick operation. Their quarter-turn design allows for rapid opening and closing, making them ideal for applications where fast response is essential.

2. Can eccentric butterfly valves handle high-pressure systems effectively?

- While double and triple eccentric butterfly valves are designed to handle higher pressures than concentric ones, it’s crucial to choose the right type and ensure it meets the specific pressure requirements of the system. Triple eccentric valves, in particular, are better suited for high-pressure applications due to their superior sealing capabilities.

3. How do I select the right type of eccentric butterfly valve for my application?

- Choosing the right valve depends on factors such as the fluid being handled, pressure and temperature requirements, the level of shut-off capability needed, and the overall system specifications. Consulting with valve experts or manufacturers can help in selecting the most suitable type and design for your specific application.

4. What are the common maintenance practices for eccentric butterfly valves?

- Regular maintenance practices include inspecting the valve for wear, checking the sealing components for damage, lubricating moving parts, and ensuring that the actuator functions correctly. It’s also essential to follow the manufacturer’s recommended maintenance schedule and guidelines to prolong the valve’s lifespan and ensure optimal performance.

5. Are eccentric butterfly valves suitable for handling abrasive or corrosive fluids?

- The suitability of eccentric butterfly valves for handling abrasive or corrosive fluids depends on the materials used in their construction. Valves made from corrosion-resistant alloys or lined with suitable materials can effectively handle corrosive fluids. For abrasive media, choosing valves with robust sealing components and durable materials can enhance their longevity in such applications. It’s essential to consult with valve manufacturers to select valves specifically designed for handling abrasive or corrosive substances.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Attempt Quiz

Question 1:

What is the primary function of an eccentric butterfly valve?

Explanation: Eccentric butterfly valves are primarily used for shutting off the flow completely in pipelines.

Question 2:

Which material is commonly used for the construction of eccentric butterfly valves?

Explanation: Stainless steel is commonly used for the construction of eccentric butterfly valves due to its corrosion resistance and durability.

Question 3:

What is the characteristic feature of an eccentric butterfly valve?

Explanation: An eccentric butterfly valve has its stem off-center from the disc, which gives it the characteristic eccentric design.

Question 4:

What is the advantage of an eccentric butterfly valve over a concentric one?

Explanation: Eccentric butterfly valves provide better sealing performance compared to concentric ones.

Question 5:

What is the typical application of high-performance eccentric butterfly valves?

Explanation: High-performance eccentric butterfly valves are typically used in high-pressure systems.

Question 6:

What is the purpose of the offset shaft in an eccentric butterfly valve?

Explanation: The offset shaft in an eccentric butterfly valve provides stability to the disc during operation.

Question 7:

What is the function of the rubber seat in an eccentric butterfly valve?

Explanation: The rubber seat in an eccentric butterfly valve creates a seal, ensuring proper closure.

Question 8:

Which industry commonly uses triple-offset eccentric butterfly valves?

Explanation: Triple-offset eccentric butterfly valves are commonly used in the oil and gas industry.

Question 9:

What is the purpose of the eccentric disc in the valve?

Explanation: The eccentric disc in the valve enhances sealing performance, ensuring tight closure.

Question 10:

Which type of media is a high-performance eccentric butterfly valve suitable for?

Explanation: High-performance eccentric butterfly valves are suitable for abrasive and corrosive media, making them versatile for various applications.