Introduction to ASME B36.10

In the world of engineering, standards play a pivotal role in ensuring safety, compatibility, and reliability across various industries. The American Society of Mechanical Engineers (ASME) stands at the forefront of developing and maintaining these standards. One such critical standard is ASME B36.10, which focuses on defining the dimensions, sizes, and specifications for pipes used in industries.

Table of Contents

Don’t miss the Detailed course on 7 Modules for Piping Codes & Standards

Enrollment Link

Background and Evolution of ASME B36.10

Engineering standards have a rich history, shaped by the need for consistency and compatibility in various industrial applications. ASME B36.10, often referred to as the “Welded and Seamless Wrought Steel Pipe” standard, has been a cornerstone of these efforts. Over time, the standard has evolved to keep up with technological advancements and changing industry requirements. ASME B36.10 has undergone revisions and updates to address emerging challenges and to incorporate new materials and manufacturing techniques, making it an integral part of modern engineering practices.

Similar Articles related to Pipe

| Topic | Weblink | Topic | Weblink |

|---|---|---|---|

| Pipe Insulation Materials | Link | ASME B36.10 | Link |

| Piping Codes & Standards | Link | Non-Metallic Pipes | Link |

| Pressure-Temperature Ratings | Link | Pipe Standards & Specifications | Link |

| Pipes for Different Fluids | Link | Pipe Coatings & Linings | Link |

| Pipe Materials Selection Guidelines | Link | Corrosion & Pipe Protection | Link |

| High-Temperature Pipes | Link | Pipe Dimensions & Sizes | Link |

| Pipe Manufacturing Processes | Link | Types of Pipes in Piping Systems | Link |

| Pipe Thickness Calculations | Link | Pipe Inspection & Testing | Link |

Understanding Piping Dimensions and Sizes

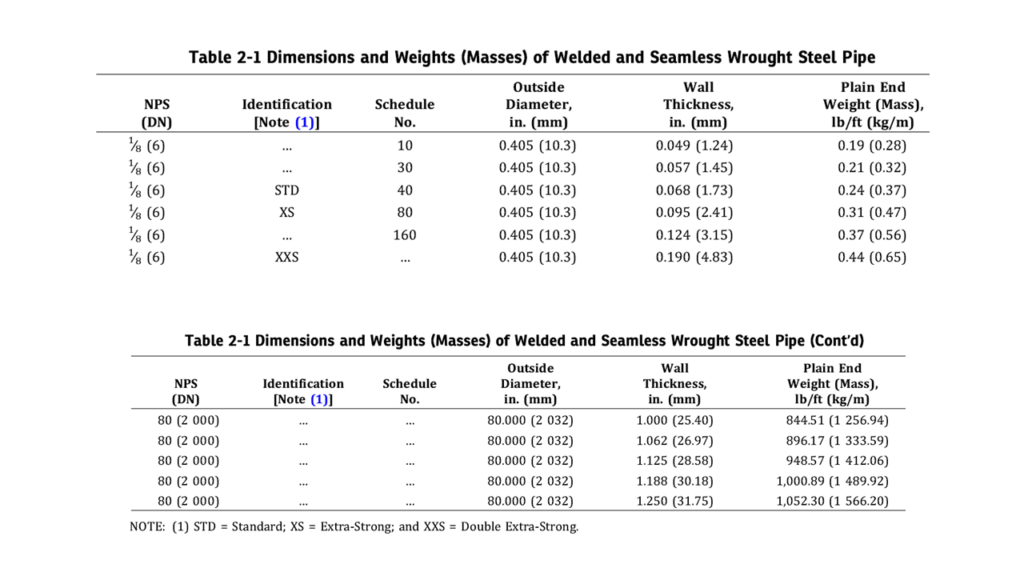

The foundation of ASME B36.10 lies in its meticulous approach to defining pipe dimensions and sizes. This standard provides a clear understanding of critical components, such as nominal size, outer diameter, and wall thickness. The primary goal of this standardization is to ensure compatibility and ease of integration across different systems. By following the guidelines laid out in ASME B36.10, engineers can confidently select and install pipes that fit seamlessly into their projects. The standard’s pipe size charts are valuable tools that simplify decision-making and promote uniformity across the industry.

Types of Pipes and Materials

ASME B36.10 encompasses a wide variety of pipes catering to different applications and industries. These pipes can be broadly categorized as seamless, welded, electric resistance welded (ERW), and submerged arc welded (SAW), each possessing unique characteristics suited for specific use cases. The choice of material is equally crucial, as it dictates the pipe’s durability, resistance to corrosion, and overall performance. Materials like carbon steel, stainless steel, and alloy steel are commonly employed in ASME B36.10-compliant pipes, each offering distinct advantages based on the application’s demands.

Don’t miss the Detailed course on 7 Modules for Piping Codes & Standards

Enrollment Link

ASME B36.10 Pipe Schedule

Pipe schedules are integral to understanding pipe dimensions and wall thicknesses in ASME B36.10. These schedules are designated by numbers and determine the pipe’s pressure and temperature handling capabilities. The higher the schedule number, the thicker the wall of the pipe. This classification system simplifies the selection process, as engineers can identify pipes suitable for specific pressure and temperature requirements with ease. ASME B36.10‘s pipe schedule system ensures that pipes are designed to withstand the conditions they are subjected to, contributing to the overall safety and efficiency of industrial operations.

Manufacturing Process and Tolerances

The manufacturing process of pipes compliant with ASME B36.10 involves a series of carefully orchestrated steps. These include forming, welding, heat treatment, and inspection to ensure consistent quality. Tolerances, as defined by the standard, outline acceptable deviations in dimensions and surface quality. Adhering to these tolerances is crucial to maintaining the integrity of the pipes and ensuring their seamless integration within various systems. Quality control throughout the manufacturing process is paramount to achieving compliance with ASME B36.10 standards and delivering pipes that meet stringent industry requirements.

Testing and Inspection Requirements

The reliability and safety of piping systems heavily depend on the quality of the pipes used. ASME B36.10 mandates thorough testing and inspection procedures to verify the pipes’ integrity. Hydrostatic testing, non-destructive examination, and dimensional checks are among the key methods employed. These processes not only ensure that pipes meet the specified standards but also detect any defects or irregularities that could compromise their performance. Adherence to ASME B36.10‘s testing and inspection requirements is non-negotiable in industries where the consequences of pipe failure can be catastrophic.

Applications and Industries

ASME B36.10-compliant pipes find their way into a myriad of industries, each with its unique set of challenges and demands. The oil and gas sector relies heavily on these pipes for the transportation of fluids over vast distances. In the petrochemical industry, they are instrumental in conveying chemicals safely. Power generation facilities utilize ASME B36.10 pipes for steam and water transport. The standard’s versatility ensures that regardless of the application, engineers have a reliable reference point for selecting the appropriate pipes that adhere to quality and safety benchmarks.

Don’t miss the Detailed course on 7 Modules for Piping Codes & Standards

Enrollment Link

Advantages and Challenges of ASME B36.10

ASME B36.10 brings several advantages to the table, making it a preferred choice in engineering projects. Interchangeability is a significant benefit; the standard ensures that pipes from different manufacturers can be seamlessly integrated, reducing compatibility concerns. Reliability is another key advantage—pipes adhering to ASME B36.10 are designed to meet stringent quality standards, minimizing the risk of failures. However, challenges do exist. Compliance costs can be substantial, particularly for small-scale projects. Additionally, adapting to evolving technologies and materials can pose challenges as the standard continues to evolve.

| Advantages of ASME B36.10 | Challenges of ASME B36.10 |

|---|---|

| 1. Interchangeability: ASME B36.10 ensures that pipes from different manufacturers can be seamlessly integrated into various systems, promoting compatibility. | 1. Compliance Costs: Adhering to ASME B36.10 standards may involve significant expenses, particularly for small-scale projects, due to material selection, testing, and inspection requirements. |

| 2. Reliability: Pipes conforming to ASME B36.10 meet stringent quality standards, reducing the risk of failures and ensuring safe and efficient operations. | 2. Technological Adaptation: Keeping up with evolving technologies and materials, while adhering to ASME B36.10, can be challenging as the standard continues to evolve over time. |

| 3. Global Acceptance: ASME B36.10 is widely recognized and accepted, making it easier to communicate specifications and requirements across international projects. | 3. Complex Decision-Making: Selecting the appropriate pipe type, size, and material while adhering to ASME B36.10 can be complex, requiring careful consideration of various factors. |

| 4. Enhanced Safety: The standard’s rigorous testing and inspection requirements ensure the quality and integrity of pipes, contributing to safer industrial operations. | 4. Limited Flexibility: ASME B36.10’s standardized specifications might not be optimal for certain unique applications, limiting design flexibility in some cases. |

| 5. Simplified Selection: Pipe schedules in ASME B36.10 aid engineers in choosing pipes based on pressure and temperature requirements, simplifying the selection process. | 5. Continuous Updates: Frequent revisions and updates to ASME B36.10 might necessitate constant monitoring to stay informed about the latest changes and requirements. |

Implementation and Compliance

Implementing ASME B36.10 standards requires a collaborative effort among manufacturers, engineers, and inspectors. It begins with the careful selection of materials and manufacturing processes that align with the standard’s specifications. Clear communication between stakeholders is essential to ensure that the final product meets the required standards. Maintaining compliance throughout a pipe’s lifecycle is equally crucial, involving regular inspections, monitoring, and maintenance. Adhering to ASME B36.10 not only ensures operational safety but also bolsters the overall efficiency and longevity of piping systems.

Future Trends and Developments

As industries advance, so do the standards that govern them. ASME B36.10 is no exception. Anticipated developments include updates to accommodate emerging materials, such as advanced alloys and composites, as well as the integration of digital technologies for enhanced monitoring and predictive maintenance. The principles of Industry 4.0, including automation and data-driven decision-making, are likely to influence the evolution of ASME B36.10. Furthermore, sustainability considerations may lead to the incorporation of eco-friendly materials and practices within the standard, contributing to more environmentally conscious engineering practices.

Don’t miss the Detailed course on 7 Modules for Piping Codes & Standards

Enrollment Link

Conclusion

In the complex world of industrial engineering, ASME B36.10 stands as a beacon of consistency, safety, and reliability. Through its meticulous definition of dimensions, sizes, and specifications, the standard ensures that pipes seamlessly integrate into various applications. ASME B36.10‘s journey from its historical roots to its modern significance reflects its adaptability to changing times. While challenges and complexities persist, the benefits of adhering to this standard are undeniable—interchangeability, reliability, and global acceptance. As industries evolve, so will ASME B36.10, continuing to shape the way we design, implement, and maintain piping systems for a safer and more efficient future.

Frequently Asked Questions (FAQs) About ASME B36.10

1. What is ASME B36.10 and why is it important in the engineering industry?

ASME B36.10 is a widely recognized standard developed by the American Society of Mechanical Engineers (ASME) that defines the dimensions, sizes, and specifications for pipes used in various industries. It plays a crucial role in ensuring compatibility, safety, and reliability across piping systems, making it an essential reference for engineers and manufacturers.

2. How does ASME B36.10 ensure compatibility across different piping systems?

ASME B36.10 provides a comprehensive framework for defining pipe dimensions, sizes, and tolerances. By adhering to these standardized specifications, engineers can confidently select and install pipes that seamlessly integrate into different applications. This promotes compatibility across various piping systems, regardless of the manufacturer or industry.

3. What is the significance of pipe schedules in ASME B36.10?

Pipe schedules in ASME B36.10 indicate the wall thickness of pipes and play a vital role in determining the pressure and temperature handling capabilities of the pipes. Higher schedule numbers correspond to thicker walls, allowing pipes to withstand higher pressures and temperatures. This classification simplifies the selection process, ensuring that the right pipes are chosen for specific operating conditions.

4. What are the key testing and inspection requirements outlined by ASME B36.10?

ASME B36.10 mandates rigorous testing and inspection procedures to ensure the quality and integrity of pipes. These include hydrostatic testing, non-destructive examination, and dimensional checks. These processes help identify defects, irregularities, or weaknesses in the pipes that could compromise their performance or safety. Adhering to these requirements is crucial for maintaining reliable and safe piping systems.

5. How does ASME B36.10 contribute to the future of piping systems?

ASME B36.10 continues to evolve to accommodate emerging technologies, materials, and industry trends. As industries embrace digitalization and automation, ASME B36.10 is likely to integrate these advancements to enhance monitoring, maintenance, and predictive capabilities of piping systems. Additionally, the standard’s role in promoting sustainability through eco-friendly materials and practices could shape the future of engineering for a more environmentally conscious world.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What does ASME B36.10 refer to?

Explanation: ASME B36.10 is the standard that covers the dimensions and tolerances of welded and seamless wrought steel pipe for high or low temperatures and pressures.

Question 2:

What is the nominal pipe size (NPS) of a pipe with an outside diameter of 10.75 inches?

Explanation: A pipe with an outside diameter of 10.75 inches corresponds to nominal pipe size (NPS) 10.

Question 3:

Which wall thickness schedule is commonly used for pipes in ASME B36.10?

Explanation: Schedule 40 is a common wall thickness schedule used for pipes in ASME B36.10. It provides a balance between strength and cost.

Question 4:

What does “NPS” stand for in ASME B36.10?

Explanation: “NPS” stands for Nominal Pipe Size in ASME B36.10. It is a standard way to refer to the size of a pipe.

Question 5:

What is the primary purpose of ASME B36.10?

Explanation: The primary purpose of ASME B36.10 is to specify the dimensions, tolerances, and materials for welded and seamless wrought steel pipes, ensuring compatibility and quality in various applications.