1. Introduction

Check valves play a crucial role in fluid control systems, ensuring the unidirectional flow of fluids and preventing backflow. Among the various types of check valves available, piston lift check valves stand out for their efficiency and reliability. In this comprehensive guide, we will delve into the history, functioning, components, applications, advantages, and standards of piston lift check valves.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

2. Brief History

The history of check valves dates back centuries, with ancient civilizations using rudimentary designs to regulate the flow of water. However, it was during the Industrial Revolution that check valves saw significant advancements. The invention of piston lift check valves marked a milestone in fluid control technology. These valves, characterized by a piston mechanism, offered superior performance, making them indispensable in various industrial applications.

3. Basic Function and Working Principle

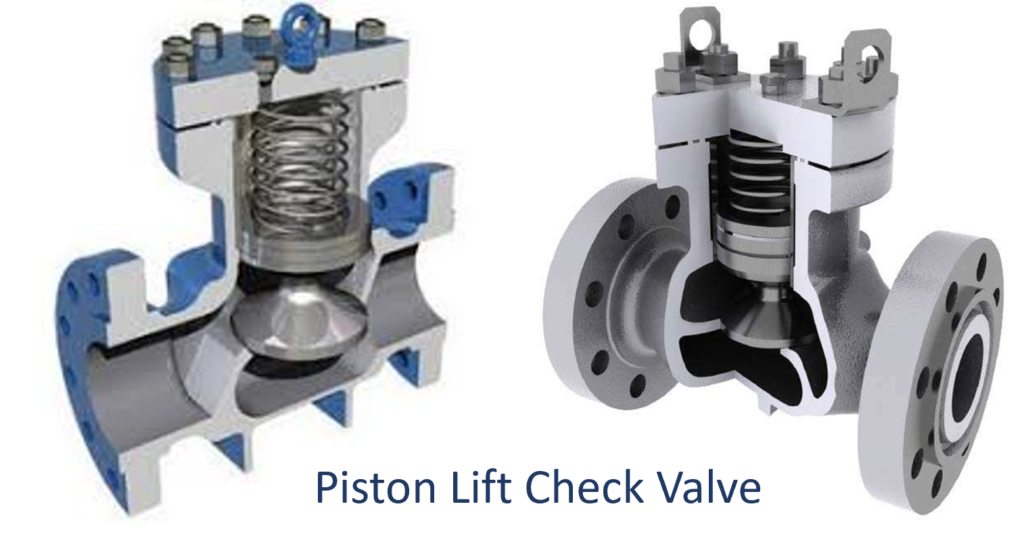

At its core, a piston lift check valve functions to allow fluid to flow in one direction while preventing reverse flow. The working principle involves the movement of a piston within the valve body. When there is forward flow, the piston is lifted, allowing fluid passage. During backflow, the piston is forced back onto the seat, sealing the valve and preventing reverse flow. This mechanism ensures the efficiency and reliability of fluid systems, making piston lift check valves a popular choice in industries requiring precise fluid control.

4. Main Components & Their Functions

Piston lift check valves consist of several essential components, each playing a specific role in ensuring proper valve operation.

- Piston: The piston is the central component responsible for regulating the flow of fluids. It moves up and down based on the direction of flow, allowing or blocking the passage of fluids.

- Seat: The seat provides a sealing surface for the piston. When the piston is in the closed position, it fits snugly against the seat, preventing any fluid from passing through.

- Body: The body of the valve houses the piston and seat, providing structural support and guiding the movement of the piston.

- Spring (Optional): In some designs, a spring is incorporated to assist the piston in returning to the closed position after the flow stops. The spring adds resilience to the valve, ensuring effective sealing.

5. Applications of Piston Lift Check Valves

Piston lift check valves find extensive applications across various industries due to their efficiency and reliability. Some notable applications include:

- Oil and Gas Industry: Piston lift check valves are used in pipelines to prevent backflow of oil and gas, ensuring the safety and integrity of the entire system.

- Water Treatment Plants: These valves are employed in water treatment facilities to control the flow of treated water and prevent contamination from backflow.

- Manufacturing Sector: Piston lift check valves are integral to manufacturing processes, where precise control of fluids is essential for product quality and consistency.

- HVAC Systems: Heating, ventilation, and air conditioning systems utilize these valves to regulate the flow of refrigerants and prevent reverse flow, ensuring efficient operation.

6. Advantages and Disadvantages

Advantages:

- Efficient Flow Control: Piston lift check valves provide precise control over fluid flow, ensuring optimal performance of industrial processes.

- Prevention of Backflow: These valves effectively prevent backflow, maintaining the integrity of pipelines and preventing contamination.

- Low Pressure Drop: The design of piston lift check valves minimizes pressure drop, allowing fluids to flow with minimal resistance.

- Suitable for Various Fluids: They can handle a wide range of fluids, including liquids and gases, making them versatile in different applications.

Disadvantages:

- Limited in High-Pressure Applications: Piston lift check valves may have limitations in high-pressure systems, where specialized high-pressure valves might be required.

- Sensitive to Particulate Contamination: The piston and seat mechanism can be sensitive to particulate contamination, requiring regular maintenance and cleaning.

- Higher Initial Installation Cost: Compared to basic check valves, piston lift check valves can have a higher initial installation cost due to their complex design.

7. Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| – Efficient Flow Control | – Limited in High-Pressure Applications |

| – Prevention of Backflow | – Sensitive to Particulate Contamination |

| – Low Pressure Drop | – Require Regular Maintenance and Cleaning |

| – Suitable for Various Fluids | – Higher Initial Installation Cost |

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

8. Codes and Standards

Piston lift check valves are governed by several industry standards to ensure their quality, performance, and safety. Some of the relevant codes and standards include:

- API 6D (Specification for Pipeline Valves): This standard outlines the requirements for pipeline valves, including piston lift check valves, ensuring their reliability and durability in various applications.

- ASME B16.34 (Valves-Flanged, Threaded, and Welding End): ASME B16.34 provides specifications for valves, including materials, dimensions, and testing procedures, ensuring uniformity and quality across different valve types.

- ISO 5208 (Industrial Valves-Pressure Testing of Valves): ISO 5208 standardizes the testing methods for industrial valves, including piston lift check valves, to assess their performance under different pressure conditions.

9. Conclusion

In conclusion, piston lift check valves play a vital role in ensuring the smooth operation of fluid systems across diverse industries. Their efficient flow control, ability to prevent backflow, and versatility in handling various fluids make them indispensable components in modern industrial processes. While they have certain limitations, such as sensitivity to particulate contamination and higher initial costs, their advantages far outweigh the drawbacks.

Understanding the working principles, components, applications, and industry standards associated with piston lift check valves is essential for engineers, technicians, and professionals involved in fluid control systems. As technology continues to advance, piston lift check valves are likely to undergo further innovations, enhancing their performance and expanding their applications.

FAQs

1. What is a piston lift check valve, and how does it differ from other types of check valves?

A piston lift check valve is a type of check valve used in fluid control systems to prevent backflow and ensure unidirectional flow. Unlike other check valves, it employs a piston mechanism to control the flow, allowing for efficient and reliable fluid regulation.

2. In which industries are piston lift check valves commonly used, and what specific applications do they serve?

Piston lift check valves find widespread applications in industries such as oil and gas, water treatment, manufacturing, and HVAC systems. They are used in pipelines, water treatment plants, manufacturing processes, and HVAC systems to regulate the flow of fluids, prevent backflow, and maintain system integrity.

3. What are the advantages of using piston lift check valves in fluid control systems?

Piston lift check valves offer several advantages, including efficient flow control, prevention of backflow, low pressure drop, and suitability for handling various fluids. These valves are known for their precise regulation of fluid flow and their ability to maintain system efficiency and safety.

4. What are the limitations or disadvantages of piston lift check valves, and how can these challenges be addressed?

Piston lift check valves have limitations, including sensitivity to particulate contamination, limitations in high-pressure applications, and higher initial installation costs. Regular maintenance and cleaning can address issues related to particulate contamination, while selecting valves designed for high-pressure environments can overcome limitations in high-pressure applications.

5. What industry standards and codes govern the manufacturing and use of piston lift check valves, and why are these standards important?

Piston lift check valves are governed by industry standards such as API 6D, ASME B16.34, and ISO 5208. These standards ensure the quality, performance, and safety of the valves. Compliance with these standards is essential to guarantee the reliability and durability of piston lift check valves in various industrial applications.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Attempt Quiz

Question 1:

What is the primary function of a piston lift check valve?

Explanation: A piston lift check valve is designed to prevent backflow in a pipeline.

Question 2:

What is the main advantage of a piston lift check valve over other types of check valves?

Explanation: Piston lift check valves provide better sealing performance compared to other types of check valves.

Question 3:

Where are piston lift check valves commonly used?

Explanation: Piston lift check valves are commonly used in oil and gas pipelines.

Question 4:

What type of motion allows a piston lift check valve to open and close?

Explanation: Piston lift check valves operate based on linear motion.

Question 5:

What is the typical material used for the piston in a piston lift check valve?

Explanation: Stainless steel is a common material used for the piston in piston lift check valves due to its durability and corrosion resistance.

Question 6:

What is the purpose of the piston in a piston lift check valve?

Explanation: The piston in a piston lift check valve is designed to prevent backflow in a pipeline.

Question 7:

What is the typical pressure rating for piston lift check valves?

Explanation: The pressure rating for piston lift check valves can vary widely, depending on the specific application and design.

Question 8:

What is the role of the spring in some piston lift check valves?

Explanation: The spring in some piston lift check valves enhances sealing and assists in the valve’s operation.

Question 9:

What is the advantage of piston lift check valves in vertical piping systems?

Explanation: Piston lift check valves help prevent water hammer in vertical piping systems.

Question 10:

What is the typical installation orientation of a piston lift check valve?

Explanation: Piston lift check valves can be installed in any orientation.