I. Introduction

In an era defined by the relentless pursuit of sustainable energy solutions, the “Power of Hydrogen” stands out as a promising and transformative force. As humanity grapples with the pressing need to reduce carbon emissions, transition away from fossil fuels, and power a more environmentally-conscious future, hydrogen takes center stage. This article serves as a comprehensive expedition into the remarkable world of hydrogen, with a laser focus on its diverse production methods, burgeoning growth trends, and its pivotal role in the reduction of carbon emissions.

We’ll also navigate through its potential as a clean and efficient fuel source, confront the financial obstacles it confronts, and shine a spotlight on the rise of ammonia as an alternative energy carrier. From the tried-and-true processes of steam reforming, to the innovative realms of coal gasification and oil reforming, we’ll explore the diverse techniques that bring hydrogen to life.

The “Power of Hydrogen” is vividly exemplified in its remarkable Compound Annual Growth Rate (CAGR) within the hydrogen production industry, fuelled by an evolving global energy landscape that’s increasingly environmentally conscious. We’ll delve deep into its dynamic impact, notably within the steel industry, where it plays a transformative role in reducing carbon emissions.

Furthermore, we’ll unravel the intricate comparison between hydrogen and electric vehicles, scrutinizing their unique advantages and hurdles, and navigate through the complex challenges surrounding the cost of fuel cells. As we navigate the “Power of Hydrogen,” we’ll cast a discerning eye on the intriguing emergence of ammonia as a more cost-effective energy carrier. It becomes evident that this humble element is poised to redefine how we harness the power of sustainable energy for a brighter and cleaner future.

Table of Contents

II. Hydrogen Production Methods

A. Steam Reforming

Understanding Steam Reforming

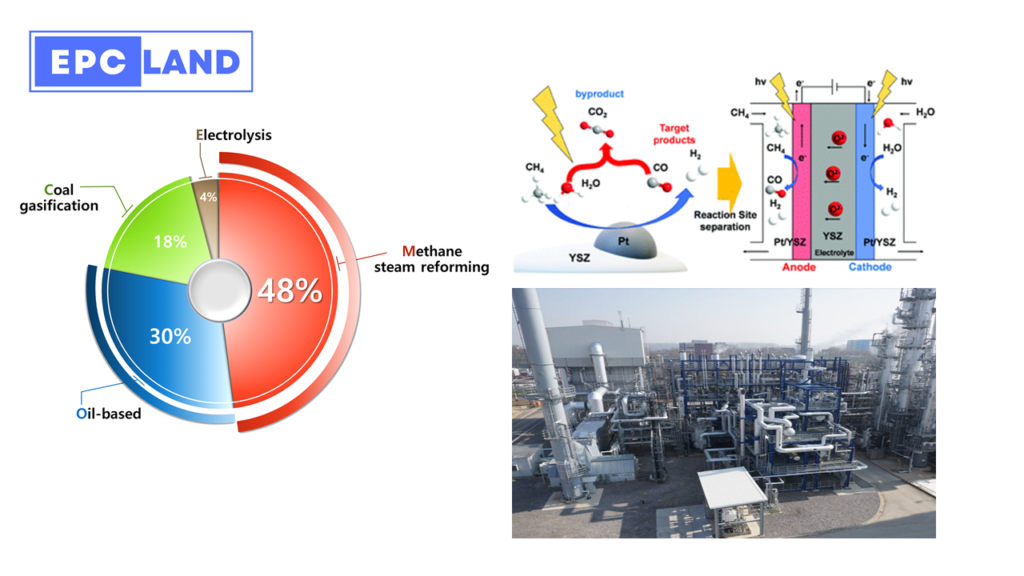

Steam reforming is a widely adopted method for hydrogen production. It involves a chemical reaction that converts hydrocarbons and water vapor into hydrogen and carbon dioxide. The process relies on catalysts and offers high efficiency, making it a cost-effective and popular choice for producing hydrogen.

Advantages and Disadvantages of Steam Reforming

While steam reforming boasts a high hydrogen yield and cost-effectiveness, it’s not without drawbacks. One significant concern is the production of carbon dioxide, a greenhouse gas. Additionally, the method depends on non-renewable feedstocks. These advantages and disadvantages make it essential to weigh the pros and cons of steam reforming in the broader context of sustainable energy production.

| Advantages of Steam Reforming | Disadvantages of Steam Reforming |

|---|---|

| High hydrogen yield | Production of carbon dioxide, a greenhouse gas |

| Cost-effective | Dependence on non-renewable feedstocks |

| Widely adopted and established method | Potential environmental impact |

| Well-developed infrastructure | Energy-intensive process |

| Compatibility with various feedstocks |

This table provides a clear side-by-side comparison of the pros and cons of steam reforming as a hydrogen production method.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

B. Coal Gasification

The Mechanism of Coal Gasification

Coal gasification is an innovative method that transforms coal into synthesis gas, consisting primarily of hydrogen and carbon monoxide. This gas can then be processed to yield hydrogen. While coal gasification holds promise in utilizing coal resources more cleanly, it presents several technological and environmental challenges.

Environmental Implications and Technological Challenges

Coal gasification raises concerns about emissions, waste management, and water usage. The carbon emissions associated with coal gasification demand innovative solutions. Overcoming these technological and environmental challenges is vital for the sustainable use of coal in hydrogen production.

C. Oil Reforming

Oil Reforming: A Hydrogen Production Method

Oil reforming involves the conversion of hydrocarbons from oil into hydrogen gas, making it crucial for industries reliant on oil-based feedstocks. This method’s significance lies in its contribution to the diversification of hydrogen production sources.

Impact on Carbon Emissions and Energy Security

As the world shifts towards cleaner energy sources, the role of oil reforming becomes essential. It influences carbon emissions and energy security, and it presents an opportunity to transform the oil industry in a more sustainable direction.

Here’s a table comparing Steam Reforming, Coal Gasification, and Oil Reforming as methods of hydrogen production:

| Aspect | Steam Reforming | Coal Gasification | Oil Reforming |

|---|---|---|---|

| Primary Feedstock | Hydrocarbons and water vapor | Coal | Hydrocarbons (usually from oil) |

| Hydrogen Yield | High | Moderate to High | Moderate to High |

| Environmental Impact | Carbon dioxide emissions, a greenhouse gas, and energy-intensive process | Carbon dioxide emissions, environmental concerns, and water usage | Carbon dioxide emissions, reliance on non-renewable resources |

| Technological Maturity | Well-established | Ongoing advancements | Well-established |

| Infrastructure | Well-developed infrastructure | Developing infrastructure | Well-developed infrastructure |

| Energy Efficiency | Energy-intensive | Energy-intensive | Energy-intensive |

| Applications | Diverse industrial applications | Potential for power generation and industrial processes | Industrial and energy production applications |

| Carbon Capture Potential | Possible with additional technologies | Possible but challenging | Possible but challenging |

This table offers a side-by-side comparison of the power of hydrogen & three hydrogen production methods, highlighting key aspects including feedstock, hydrogen yield, environmental impact, technological maturity, infrastructure, energy efficiency, applications, and carbon capture potential. Each method has its unique advantages and challenges, making them suitable for different applications and contexts.

III. Hydrogen Production Growth

The global hydrogen production industry is expected to grow at a compound annual growth rate (CAGR) of 57% between 2019 and 2030. This remarkable growth is being driven by a number of factors, including:

- Environmental consciousness: As the world becomes more aware of the dangers of climate change, there is a growing demand for clean and sustainable energy sources. Hydrogen is a clean-burning fuel that produces only water vapor when combusted, making it an ideal alternative to fossil fuels.

- Governmental support: Governments around the world are providing financial and policy support to the hydrogen industry in an effort to reduce carbon emissions and promote clean energy development.

- Technological advancements: Technological breakthroughs in hydrogen production, storage, and transportation are making hydrogen more affordable and accessible.

B. Factors Driving Hydrogen Production Growth

The following are the key factors driving hydrogen production growth:

- Supportive policies and incentives: Governments around the world are providing financial and policy support to the hydrogen industry in an effort to reduce carbon emissions and promote clean energy development. These incentives can include tax breaks, subsidies, and investment grants.

- Technological breakthroughs: Technological breakthroughs in hydrogen production, storage, and transportation are making hydrogen more affordable and accessible. For example, the cost of electrolyzers, which are used to produce power of hydrogen using electricity and water, has fallen significantly in recent years.

- Global transition towards green energy: The world is transitioning to a clean energy economy, and hydrogen is playing a major role in this transition. Hydrogen can be used in a variety of applications, including transportation, power generation, and industrial processes, without producing greenhouse gas emissions.

The global hydrogen production industry is experiencing remarkable growth due to a number of factors, including environmental consciousness, governmental support, and technological advancements. Hydrogen is a versatile and clean-burning fuel with the potential to play a major role in the global transition to a clean energy economy.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

IV. Carbon Emissions and Power of Hydrogen

A. Contribution of Various Sectors to Carbon Emissions

The following are the major sectors that contribute to carbon emissions:

- Energy: The energy sector is the largest contributor to carbon emissions, accounting for about 60% of global emissions. This includes emissions from power generation, transportation, and heating and cooling.

- Industry: The industrial sector is the second-largest contributor to carbon emissions, accounting for about 20% of global emissions. This includes emissions from manufacturing, mining, and construction.

- Agriculture: The agriculture sector is the third-largest contributor to carbon emissions, accounting for about 10% of global emissions. This includes emissions from livestock production, crop cultivation, and deforestation.

B. Steelmaking: A Key Sector Reducing Carbon Emissions

The steel industry is a major source of carbon emissions, accounting for about 8% of global emissions. The traditional steelmaking process involves the use of coal and other fossil fuels to reduce iron ore to pig iron, which is then converted into steel. This process produces a significant amount of carbon dioxide.

Hydrogen can be used to reduce carbon emissions in the steel industry in a number of ways. One way is to use hydrogen to produce direct reduced iron (DRI), which is a semi-finished steel product that can be used to produce steel without the use of coal. Another way to use hydrogen is to use it in the blast furnace process to replace some of the coal used.

The use of hydrogen in steelmaking is still in its early stages, but there are a number of projects underway to develop and commercialize these technologies. If these technologies are successful, they could significantly reduce carbon emissions from the steel industry.

In addition to the steel industry, power of hydrogen can also be used to reduce carbon emissions in other sectors, such as power generation, transportation, and industry. For example, hydrogen can be used to generate electricity in fuel cells, which are more efficient and cleaner than traditional combustion engines. Hydrogen can also be used to produce synthetic fuels for use in conventional vehicles.

Overall, hydrogen has the potential to play a major role in reducing global carbon emissions. As hydrogen production technologies continue to improve and the cost of hydrogen comes down, we can expect to see even more innovative and groundbreaking applications for this versatile energy carrier.

V. Power of Hydrogen as a Fuel

A. Coexistence with Electric Vehicles

Electric vehicles (EVs) and hydrogen fuel cell vehicles (HFCEVs) represent the evolving landscape of transportation, each harnessing the power of hydrogen in its unique way. Both technologies offer a number of advantages over traditional gasoline-powered vehicles, including zero emissions, reduced operating costs, and improved performance.

However, there are also some key differences between EVs and HFCEVs. One of the biggest differences is the way they store energy. EVs store energy in batteries, while HFCEVs store energy in hydrogen. This difference has a number of implications for the performance, refueling times, and infrastructure requirements of these vehicles.

B. Hydrogen vs. Electric Vehicles: A Comparative Analysis

Energy efficiency: HFCEVs are generally more energy-efficient than EVs. This is because hydrogen has a higher energy density than lithium-ion batteries, meaning that it can store more energy in a smaller volume.

Infrastructure: EV infrastructure is currently more developed than HFCEV infrastructure. There are more EV charging stations than hydrogen refueling stations worldwide.

Environmental impact: Both EVs and HFCEVs have a lower environmental impact than gasoline-powered vehicles. However, HFCEVs produce some water vapor when they operate, while EVs produce no emissions at all.

C. Hydrogen’s Energy-to-Weight Ratio and Long-Range Capabilities

Hydrogen has a very high energy-to-weight ratio, meaning that it has a lot of energy for its weight. This makes power of hydrogen an ideal fuel for applications where long range is important, such as aviation and long-haul transportation.

For example, a hydrogen-powered airplane could fly much further than a battery-powered airplane. Hydrogen-powered trucks could also travel much further without refueling than battery-powered trucks.

D. Charging Times: Hydrogen vs. Lithium-Ion Batteries

Hydrogen fuel cell vehicles can be refueled in a matter of minutes, similar to gasoline-powered vehicles. Lithium-ion battery-powered electric vehicles, on the other hand, can take several hours to recharge.

The fast refueling times of hydrogen fuel cell vehicles are a major advantage, especially for applications where vehicles need to be on the road for long periods of time, such as commercial trucks and taxis.

Hence we can conclude the section by saying, Hydrogen fuel cell vehicles and electric vehicles are two pioneering technologies that harness the power of hydrogen to reduce our dependence on fossil fuels. While each technology has its own advantages and disadvantages, they are complementary rather than competitive.

Hydrogen fuel cell vehicles are better suited for applications where long range and fast refueling are important. Electric vehicles are better suited for applications where short range and low cost are important.

As both technologies continue to develop and mature, we can expect to see them play an increasingly important role in the global transportation sector.

VI. The Cost of Fuel Cells

A. The Expense of Fuel Cells

Fuel cells are a critical component of hydrogen-based energy systems. They convert hydrogen and oxygen into electricity, producing water as the only byproduct. Fuel cells are efficient, clean, and quiet, making them ideal for a variety of applications, including transportation, power generation, and portable electronics.

However, fuel cells are often considered more expensive than traditional combustion engines. This is due to a number of factors, including the high cost of platinum, which is used as a catalyst in fuel cells.

B. The Role of Platinum in Fuel Cell Costs

Platinum is a precious metal that is essential for the operation of fuel cells. Platinum acts as a catalyst, helping to speed up the reaction between hydrogen and oxygen.

Platinum is a relatively rare metal, and its price can fluctuate significantly. This makes fuel cell costs more volatile than the costs of traditional combustion engines.

Efforts to Reduce Fuel Cell Costs

Researchers and industry are working on a number of ways to reduce the cost of fuel cells. One approach is to reduce the amount of platinum used in fuel cells. Another approach is to develop new catalysts that are just as effective as platinum but less expensive.

In addition, researchers are working on improving the durability of fuel cells so that they can last longer. This would reduce the operating costs of fuel cells and make them more cost-competitive with traditional combustion engines.

Hence we can say, The high cost of fuel cells is one of the main barriers to their widespread adoption. However, researchers and industry are making progress in reducing the cost of fuel cells. As fuel cell costs continue to come down, we can expect to see them used in a wider range of applications.

Additional Thoughts

In addition to the efforts mentioned above, governments are also playing a role in making fuel cells more affordable. For example, the US Department of Energy has a number of programs in place to support the development and commercialization of fuel cell technologies.

With the support of governments and industry, fuel cells have the potential to become a more cost-competitive alternative to traditional combustion engines in the near future.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

VII. Ammonia as an Energy Carrier

A. The Potential of Ammonia

Ammonia is a compound of nitrogen and hydrogen, and it can be easily converted back to hydrogen when needed. Ammonia has a number of advantages over power of hydrogen as an energy carrier, including:

- It is easier to store and transport than hydrogen.

- It is less expensive than hydrogen.

- It is less flammable than hydrogen.

Potential Advantages of Ammonia as an Energy Carrier

Ammonia has a number of potential advantages as an energy carrier, including:

- Cost efficiency: Ammonia is less expensive to produce and transport than hydrogen.

- Storage density: Ammonia has a higher energy density than liquid hydrogen, meaning that it can store more energy in a smaller volume.

- Safety: Ammonia is less flammable than hydrogen, making it safer to store and transport.

- Versatility: Ammonia can be used in a variety of applications, including transportation, power generation, and industry.

B. Cost Efficiency: Ammonia vs. Hydrogen

Ammonia is generally less expensive to produce and transport than hydrogen. This is because ammonia is a liquid at room temperature and pressure, while hydrogen must be liquefied at very low temperatures or compressed to very high pressures.

Additionally, ammonia has a higher energy density than liquid hydrogen, meaning that more energy can be stored in a given volume of ammonia. This reduces the cost of transporting and storing ammonia.

Hence it can be concluded that Ammonia is a promising alternative to traditional hydrogen storage methods. It is less expensive, easier to store and transport, and less flammable than hydrogen. Ammonia also has the potential to be used in a variety of applications, including transportation, power generation, and industry.

As the world transitions to a clean energy future, ammonia is expected to play an increasingly important role as an energy carrier.

VIII. Conclusion

A. Key Takeaways

In understanding the “Power of Hydrogen,” several key insights emerge:

- Hydrogen, though the most abundant element in the universe, is rarely found in its pure form on Earth.

- Diverse methods, including steam reforming, coal gasification, and electrolysis, enable hydrogen production.

- Hydrogen’s applicability spans various sectors, encompassing transportation, power generation, and industry.

- Hydrogen fuel cell vehicles offer advantages such as extended range and rapid refueling, setting them apart from battery electric vehicles.

- The emergence of ammonia as an alternative to traditional hydrogen storage methods presents cost-efficiency and safety benefits.

B. The Growing Importance of Hydrogen in a Sustainable Energy Future

As we recognize the “Power of Hydrogen,” its burgeoning significance in steering us toward a sustainable energy future becomes evident. Hydrogen is a clean fuel, yielding only water vapor when burned, and its utility extends to renewable energy storage and transport.

Hydrogen holds the potential to curtail greenhouse gas emissions across diverse sectors, including transportation, power generation, and industry. Moreover, it can facilitate the production of synthetic fuels compatible with existing infrastructure.

This growing significance of hydrogen translates into substantial investment in production and applications. Governments and enterprises worldwide are channeling resources into hydrogen projects, ushering in a period of rapid growth within the hydrogen industry.

C. The Need for Continued Research and Innovation

While the “Power of Hydrogen” promises a pivotal role in the transition to a sustainable energy future, challenges remain. The cost of hydrogen production and the development of hydrogen infrastructure are pressing issues.

The solution lies in perpetuating research and innovation, addressing these challenges, and devising inventive ways to harness the potential of hydrogen. Governments and businesses must persist in their investments in hydrogen research and development.

In conclusion, the “Power of Hydrogen” offers a clean and versatile path to a sustainable energy future. To fully realize this potential, ongoing investment in research and development, along with the resolution of production and infrastructure challenges, is imperative.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

FAQs on Power of Hydrogen

here are five frequently asked questions (FAQs) related to the article “The Power of Hydrogen: Production, Applications, and Challenges,” along with their respective answers:

1. What is the primary advantage of hydrogen fuel cell vehicles over traditional gasoline-powered vehicles?

Answer: The primary advantage of hydrogen fuel cell vehicles (HFCEVs) is their zero emissions. Unlike gasoline-powered vehicles, HFCEVs produce no harmful tailpipe emissions, making them a cleaner and more environmentally friendly transportation option.

2. How does the energy efficiency of hydrogen fuel cell vehicles compare to electric vehicles (EVs)?

Answer: Hydrogen fuel cell vehicles are generally more energy-efficient than electric vehicles. This is because hydrogen has a higher energy density than lithium-ion batteries, allowing it to store more energy in a smaller volume.

3. Are there more charging stations for electric vehicles (EVs) or hydrogen refueling stations for hydrogen fuel cell vehicles (HFCEVs) worldwide?

Answer: Currently, there are more EV charging stations than hydrogen refueling stations around the world. This discrepancy highlights the need for further development of hydrogen refueling infrastructure to match the convenience of EV charging.

4. What is the main environmental difference between hydrogen fuel cell vehicles (HFCEVs) and electric vehicles (EVs)?

Answer: While both HFCEVs and EVs significantly reduce environmental impact compared to gasoline-powered vehicles, HFCEVs produce water vapor as their only emissions during operation, whereas EVs produce no emissions at all.

5. In what types of applications does hydrogen’s high energy-to-weight ratio and long-range capabilities make it particularly advantageous?

Answer: Hydrogen’s high energy-to-weight ratio makes it ideal for applications where extended range is crucial, such as aviation and long-haul transportation. Hydrogen-powered vehicles, like airplanes and trucks, can cover significantly greater distances compared to their battery-powered counterparts, making them more suitable for long-range applications.

Quiz on Hydrogen

II. Hydrogen Production Methods

Which of the following is a common method of hydrogen production?

Explanation: Steam methane reforming is a common method for hydrogen production.

III. Hydrogen Production Growth

What has driven the recent growth in hydrogen production?

Explanation: Increased interest in renewable energy sources has driven recent growth in hydrogen production.

B. Factors Driving Hydrogen Production Growth

What is one of the key factors driving the growth of hydrogen production?

Explanation: Government incentives and policies are key factors driving the growth of hydrogen production.

IV. Carbon Emissions and Power of Hydrogen

How does hydrogen production contribute to reducing carbon emissions?

Explanation: Hydrogen production contributes to reducing carbon emissions by producing hydrogen from renewable sources, which do not emit carbon.

V. Power of Hydrogen as a Fuel

What makes hydrogen a valuable fuel source?

Explanation: Hydrogen is valuable as a fuel source due to clean energy production and high energy density.

VI. The Cost of Fuel Cells

What impacts the cost of fuel cells?

Explanation: The cost of fuel cells is impacted by the price of platinum used in fuel cells.

VII. Ammonia as an Energy Carrier

How is ammonia used as an energy carrier?

Explanation: Ammonia is used as an energy carrier by storing hydrogen in liquid form.