1. What is the primary function of centrifugal pump impellers?

Choose the correct statement:

Explanation: Centrifugal pump impellers convert rotational energy from the motor into kinetic energy of the fluid, driving the pumping process.

2. What is a key feature of open impellers?

Select the correct characteristic:

Explanation: Open impellers have open vanes at the front, making them ideal for clear liquids and easy inspection and cleaning.

3. What is the advantage of semi-open impellers?

Choose the correct statement:

Explanation: Semi-open impellers offer a compromise between open and closed designs, allowing for cleaning while handling small solids in the fluid.

4. What type of impellers is preferred for handling liquids with solids or abrasives?

Select the correct option:

Explanation: Closed impellers with fully enclosed vanes are preferred for handling liquids with solids or abrasives.

5. What factors influence the pump’s performance related to the impeller?

Choose the correct statement:

Explanation: The number of vanes, diameter, and width of the impeller are crucial factors influencing the pump’s performance.

6. What is the impact of vane shape, angle, and diameter on the pump’s performance?

Choose the correct statement:

Explanation: The specific design and dimensions of the impeller, including vane shape, angle, and diameter, directly influence flow rate, pressure head, and efficiency.

7. Why is understanding centrifugal pump impellers crucial for pump selection?

Choose the correct statement:

Explanation: Understanding centrifugal pump impellers is crucial for choosing the right pump for specific applications and ensuring efficient pumping operations.

Don’t Miss the Relevant Topics on Centrifugal Pumps

| Topics on Centrifugal Pumps | Topics on Centrifugal Pumps |

| Working Principle of Centrifugal Pumps | Centrifugal Pump Mechanical Seals |

| Centrifugal Pump Bearings | Centrifugal Pump Shaft |

| Types of Centrifugal Pumps | Centrifugal Pump Impellers |

| Centrifugal Pump Casing |

Short Article on Centrifugal Pump Impellers

Understanding Centrifugal Pump Impellers: The Heart of the Pump’s Performance

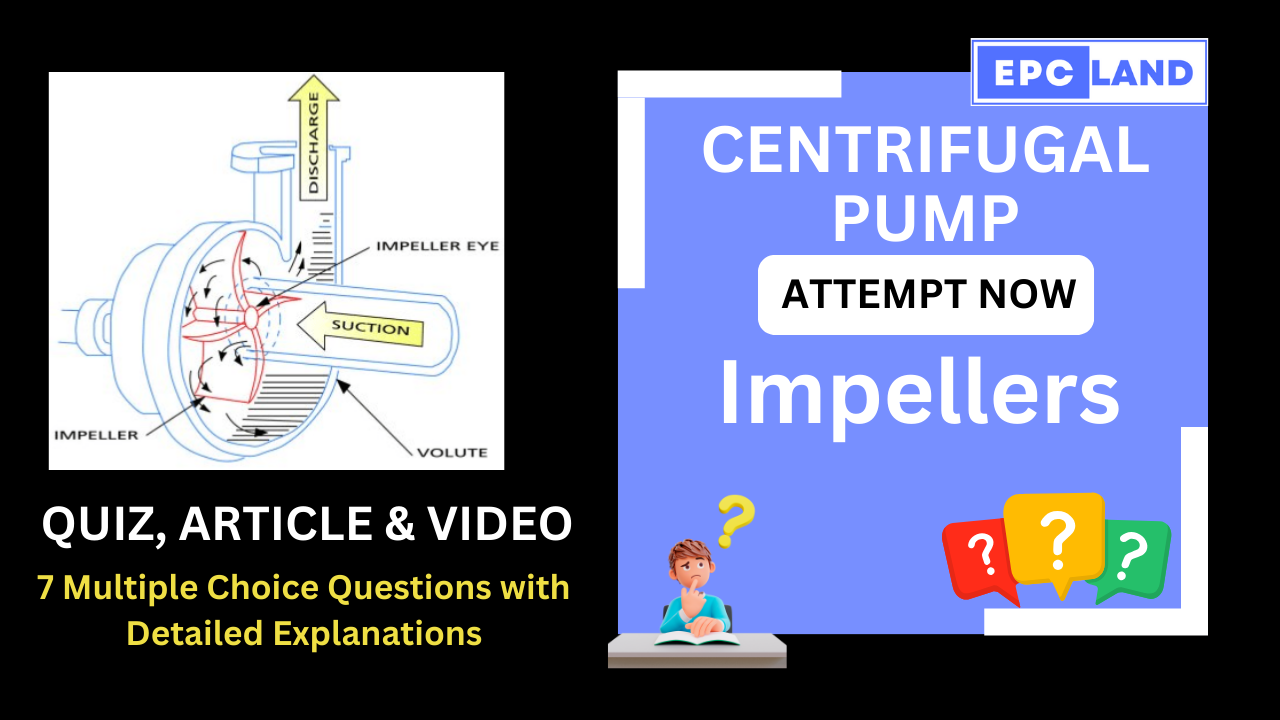

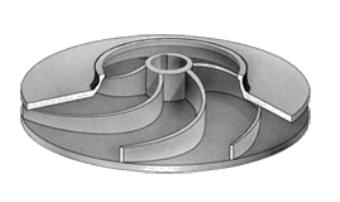

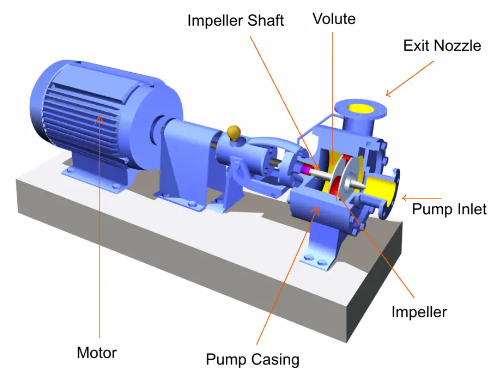

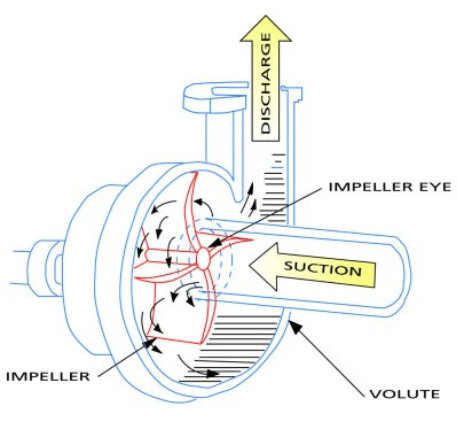

Centrifugal pumps are the workhorses of various industries, relying heavily on their impellers for efficient operation. These rotating components, often described as the “heart” of the pump, convert rotational energy from the motor into kinetic energy of the fluid, driving the entire pumping process.

Delving into Impeller Design:

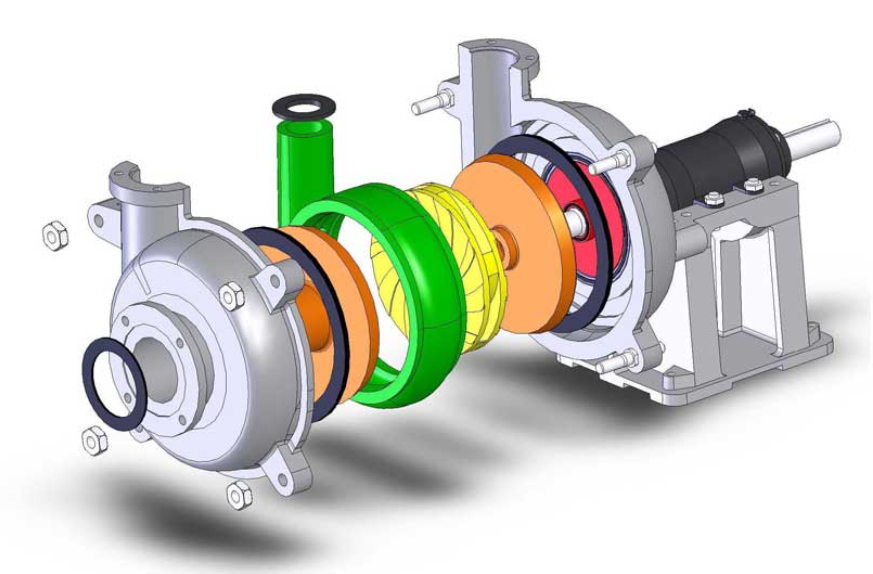

Two main types of impellers are commonly used:

- Open Impellers: Featuring open vanes at the front, these impellers offer easy inspection and cleaning, making them ideal for clear liquids.

- Semi-Open Impellers: These offer a compromise between open and closed designs, allowing for cleaning while handling small solids in the fluid.

For handling liquids with solids or abrasives, closed impellers with fully enclosed vanes become the preferred choice.

Unveiling Key Characteristics:

The number of vanes, diameter, and width of the impeller are crucial factors influencing the pump’s performance.

- Number of Vanes: Varies based on the pump type and desired performance. More vanes generally translate to higher pressure head but lower flow rate.

- Diameter and Width: Determined by the pump’s duty requirements, directly impacting its flow rate and pressure.

- Material: Typically cast iron or stainless steel, chosen based on the fluid being pumped and its corrosive properties.

Impeller’s Impact on Performance:

The specific design and dimensions of the impeller significantly influence the overall performance of the pump. Factors like vane shape, angle, and diameter directly affect flow rate, pressure head, and efficiency.

Conclusion:

Understanding the design, types, and characteristics of centrifugal pump impellers is crucial for choosing the right pump for specific applications and ensuring efficient and effective pumping operations. By focusing on the impeller, we gain valuable insights into the heart of the pump’s functionality.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.