1. Single-Stage vs. Multi-Stage: Types of Centrifugal Pumps

What distinguishes a single-stage centrifugal pump from a multi-stage pump?

Explanation: A single-stage pump has one impeller, while a multi-stage pump features multiple impellers arranged in series for higher pressure capabilities.

2. Axial vs. Radial Flow

In an axial flow centrifugal pump, how does the fluid flow in relation to the shaft axis?

Explanation: In an axial flow pump, the fluid flows predominantly parallel to the axis of the shaft.

3. Open vs. Closed Impeller

What distinguishes an open impeller from a closed impeller in a centrifugal pump?

Explanation: An open impeller has vane openings, allowing visual inspection and cleaning, while a closed impeller is fully enclosed and suitable for handling liquids with solids or abrasives.

4. Horizontal vs. Vertical

What is a common application area for a horizontal centrifugal pump?

Explanation: Horizontal centrifugal pumps are commonly used for above-ground applications with easy access for maintenance.

5. Factors for Choosing Centrifugal Pump

Which factor is NOT typically considered when choosing the right centrifugal pump?

Explanation: Motor power is not typically considered when choosing a centrifugal pump; instead, factors like flow rate, pressure head, and liquid properties are crucial considerations.

6. Benefits of Diverse Centrifugal Pump Options

How do diverse centrifugal pump options contribute to pumping operations?

Explanation: Diverse centrifugal pump options contribute to pumping operations by minimizing energy consumption, reducing wear and tear, and enhancing versatility.

7. Conclusion

Why is understanding the different types of centrifugal pumps important for industrial applications?

Explanation: Understanding the different types of centrifugal pumps is important for making informed choices to meet the specific needs of each application, ensuring efficient, reliable, and cost-effective pumping operations across diverse industries.

Don’t Miss the Relevant Topics on Centrifugal Pumps

| Topics on Centrifugal Pumps | Topics on Centrifugal Pumps |

| Working Principle of Centrifugal Pumps | Centrifugal Pump Mechanical Seals |

| Centrifugal Pump Bearings | Centrifugal Pump Shaft |

| Types of Centrifugal Pumps | Centrifugal Pump Impellers |

| Centrifugal Pump Casing |

Short Article on Types of Centrifugal Pumps

Unveiling the Diversity: Exploring Various Types of Centrifugal Pumps

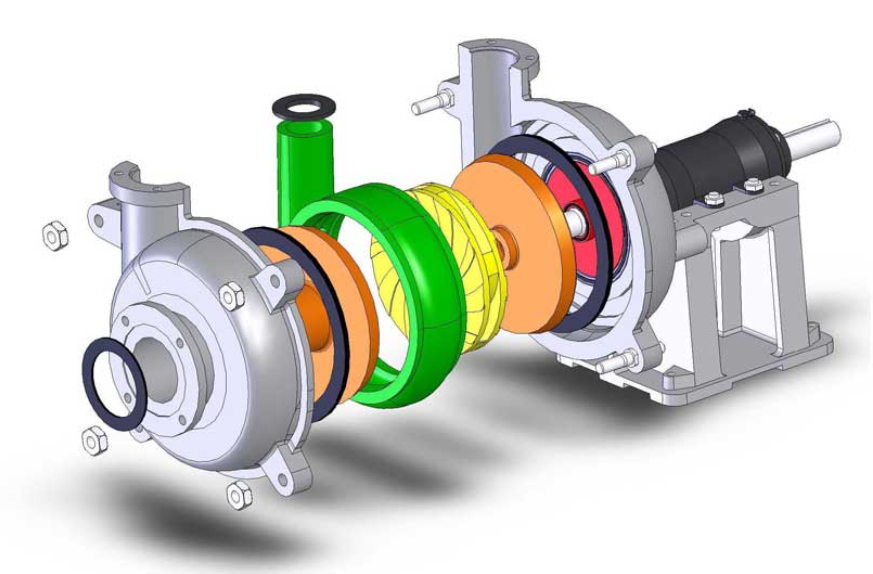

Centrifugal pumps are omnipresent in our modern world, driving the flow of liquids across diverse industries. Their versatility stems from the different types available, each with unique characteristics tailored to specific applications.

Delving into the Types:

- Single-Stage vs. Multi-Stage:

- Single-Stage: Ideal for low-pressure applications, featuring one impeller and offering simple design and ease of maintenance.

- Multi-Stage: Employ multiple impellers arranged in series, providing higher pressure capabilities for demanding applications.

- Axial vs. Radial Flow:

- Axial: Fluid flows predominantly parallel to the axis of the shaft, suitable for high flow rates at low pressure.

- Radial: Fluid flows primarily perpendicular to the axis, delivering moderate flow rates at high pressure.

- Open vs. Closed Impeller:

- Open: Vane openings allow for visual inspection and cleaning, ideal for clear liquids.

- Closed: Fully enclosed vanes handle liquids with solids or abrasives.

- Horizontal vs. Vertical:

- Horizontal: Commonly used for above-ground applications with easy access for maintenance.

- Vertical: Suitable for limited space and submerged installations, requiring minimal floor space.

Matching the Pump to the Need:

Choosing the right type of centrifugal pump requires considering various factors:

- Flow rate: The desired rate of fluid transfer.

- Pressure head: The required pressure to deliver the fluid to its destination.

- Liquid properties: Viscosity, abrasiveness, and presence of solids.

- Space constraints: Available space for installation and maintenance.

Benefits of Diverse Options:

The wide variety of centrifugal pumps ensures optimal solutions for specific applications:

- Increased efficiency: Matching the pump type to the duty point minimizes energy consumption and maximizes performance.

- Improved reliability: Selecting the appropriate pump for the fluid and operating conditions reduces wear and tear, leading to a longer lifespan.

- Enhanced versatility: Diverse options cater to various needs, from low-pressure applications to demanding industrial processes.

Conclusion:

By understanding the different types of centrifugal pumps and their unique characteristics, we can make informed choices to meet the specific needs of each application. This understanding ensures efficient, reliable, and cost-effective pumping operations across diverse industries.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.