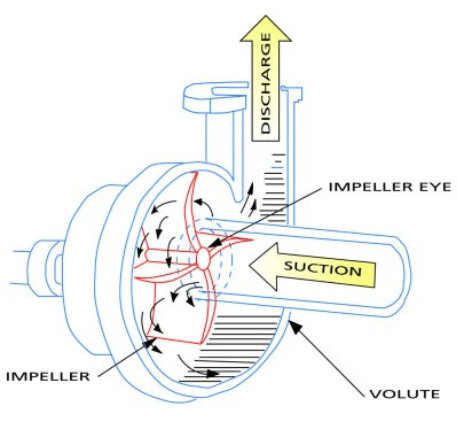

1. Working Principle

How do centrifugal pumps work based on their working principle?

Explanation: Centrifugal pumps work by using a rotating impeller to create centrifugal force, which propels the fluid outwards and increases its pressure.

2. Centrifugal Pump Types

What distinguishes multi-stage pumps from single-stage pumps?

Explanation: Multi-stage pumps have multiple impellers arranged in series, distinguishing them from single-stage pumps with a single impeller.

3. Centrifugal Pump Components

Which component of a centrifugal pump creates the centrifugal force to propel the fluid?

Explanation: The impeller is the component that creates the centrifugal force to propel the fluid in a centrifugal pump.

4. Applications of Centrifugal Pumps

In which application are centrifugal pumps commonly used to pump water from wells, rivers, and lakes?

Explanation: Centrifugal pumps are commonly used for water supply applications, pumping water from wells, rivers, and lakes.

5. Advantages of Centrifugal Pumps

What is one of the advantages of centrifugal pumps related to their design and maintenance?

Explanation: One advantage of centrifugal pumps is their simplicity in design and ease of maintenance.

6. Disadvantages of Centrifugal Pumps

What is a critical requirement for the proper operation of centrifugal pumps, and insufficient levels can lead to cavitation?

Explanation: Centrifugal pumps require a minimum net positive suction head (NPSH) for proper operation, and insufficient levels can lead to cavitation.

7. Conclusion

What knowledge about centrifugal pumps can help you choose the right pump for specific needs?

Explanation: Understanding the working principle, types, components, applications, advantages, and disadvantages of centrifugal pumps can help in choosing the right pump for specific needs.

List of Topics on Centrifugal Pumps

| Topics on Centrifugal Pumps | Topics on Centrifugal Pumps |

| Working Principle of Centrifugal Pumps | Centrifugal Pump Mechanical Seals |

| Centrifugal Pump Bearings | Centrifugal Pump Shaft |

| Types of Centrifugal Pumps | Centrifugal Pump Impellers |

| Centrifugal Pump Casing |

Short Article on Centrifugal Pumps

Working Principle: Centrifugal pumps work by using a rotating impeller to create centrifugal force, which propels the fluid outwards and increases its pressure. The fluid then exits the pump through the outlet with increased pressure and velocity.

Types of Centrifugal Pumps:

- Single-stage pumps: These pumps have a single impeller and are suitable for low-pressure applications.

- Multi-stage pumps: These pumps have multiple impellers arranged in series and are used for high-pressure applications.

- End-suction pumps: These pumps have the suction port located at the end of the shaft and are commonly used in industrial and commercial applications.

- In-line pumps: These pumps have the suction and discharge ports located on the same side of the pump and are often used in residential and light commercial applications.

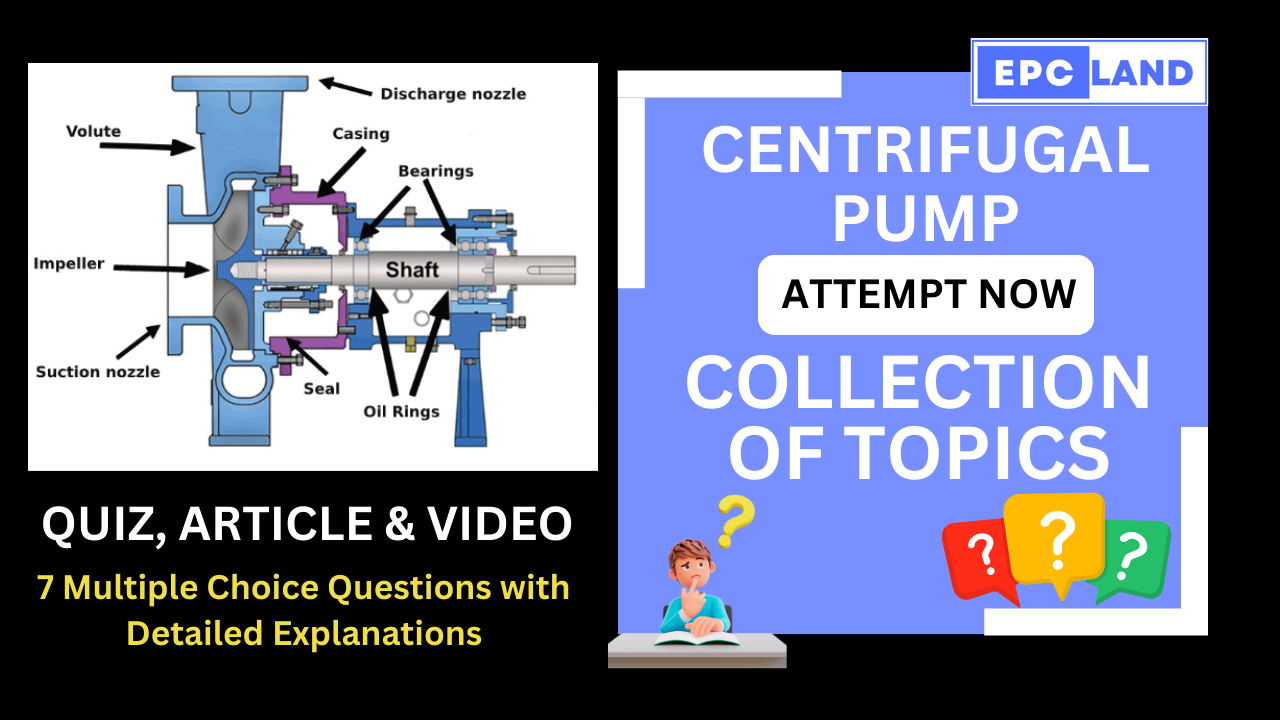

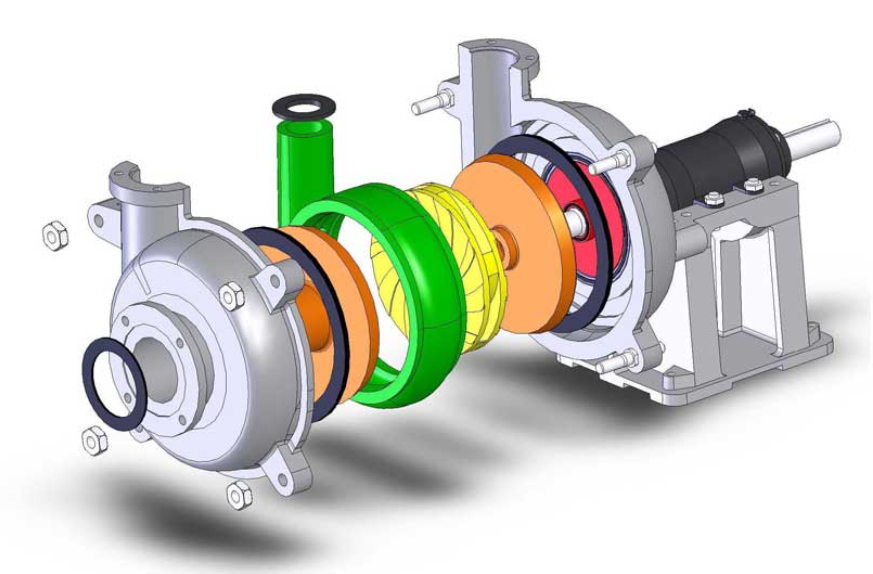

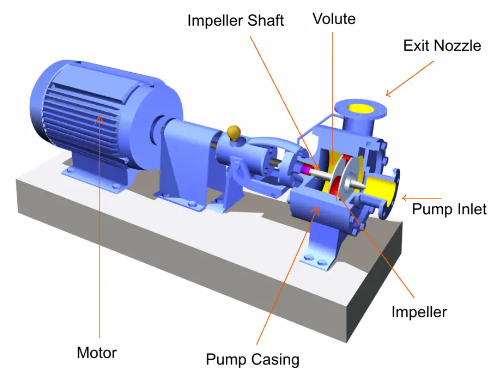

Centrifugal Pump Components:

- Impeller: The impeller is the rotating component that creates the centrifugal force that propels the fluid.

- Casing: The casing is the housing that surrounds the impeller and contains the fluid.

- Shaft: The shaft is the rotating rod that connects the impeller to the motor.

- Bearings: The bearings support the shaft and reduce friction.

- Seals: The seals prevent the fluid from leaking out of the pump.

Applications of Centrifugal Pumps:

Centrifugal pumps are used in a wide variety of applications, including:

- Water supply: Centrifugal pumps are used to pump water from wells, rivers, and lakes to homes, businesses, and industries.

- Sewerage: Centrifugal pumps are used to pump wastewater from homes, businesses, and industries to treatment plants.

- Irrigation: Centrifugal pumps are used to pump water from rivers and lakes to agricultural fields.

- Industrial processes: Centrifugal pumps are used in a variety of industrial processes, such as chemical processing, food processing, and manufacturing.

Advantages of Centrifugal Pumps:

Centrifugal pumps offer a number of advantages, including:

- Simplicity: Centrifugal pumps are relatively simple in design and easy to maintain.

- Versatility: Centrifugal pumps are available in a wide range of sizes and capacities, making them suitable for a variety of applications.

- Efficiency: Centrifugal pumps are generally very efficient, especially when operating at near-design conditions.

- Durability: Centrifugal pumps are well-built and can withstand a wide range of operating conditions.

Disadvantages of Centrifugal Pumps:

Centrifugal pumps also have some disadvantages, including:

- NPSH requirement: Centrifugal pumps require a minimum net positive suction head (NPSH) to operate properly. If the NPSH is too low, the pump may cavitate, which can damage the pump and reduce its performance.

- Sensitive to flow changes: Centrifugal pumps are sensitive to changes in flow rate. If the flow rate is too low, the pump may overheat. If the flow rate is too high, the pump may cavitate.

- Cost: Centrifugal pumps can be expensive, especially for large pumps and pumps made of exotic materials.

Conclusion:

Centrifugal pumps are versatile and efficient pumps that are used in a wide variety of applications. By understanding the working principle, types, components, applications, advantages, and disadvantages of centrifugal pumps, you can choose the right pump for your specific needs.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.