1. Introduction

Globe valves are fundamental components in various industries, playing a crucial role in regulating fluid flow. Their significance lies in their ability to precisely control the flow rate of liquids and gases within pipelines. This article provides an in-depth exploration of Y-pattern globe valves, from their historical origins to their modern applications, components, advantages, and associated codes and standards.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

2. Brief History

Globe valves have a rich history dating back centuries. The earliest globe valves were simple devices used by ancient civilizations to control the flow of water. Over time, these valves evolved, incorporating innovations such as the globe-shaped body, which led to more precise control of fluid flow. In the 19th century, with the advent of the industrial revolution, globe valves became essential components in steam engines and other machinery, further driving their development.

3. Basic Function and Working Principle

At its core, a Y-pattern globe valve is designed to regulate fluid flow by moving a disk or plug against the flow stream. This movement is controlled by a stem, which is connected to an actuator. When the valve is open, the disk is lifted, allowing fluid to pass through the valve. Conversely, closing the valve presses the disk against the seat, stopping the flow completely. The unique Y-shaped design of these valves minimizes pressure drop, making them ideal for applications where pressure loss must be minimized.

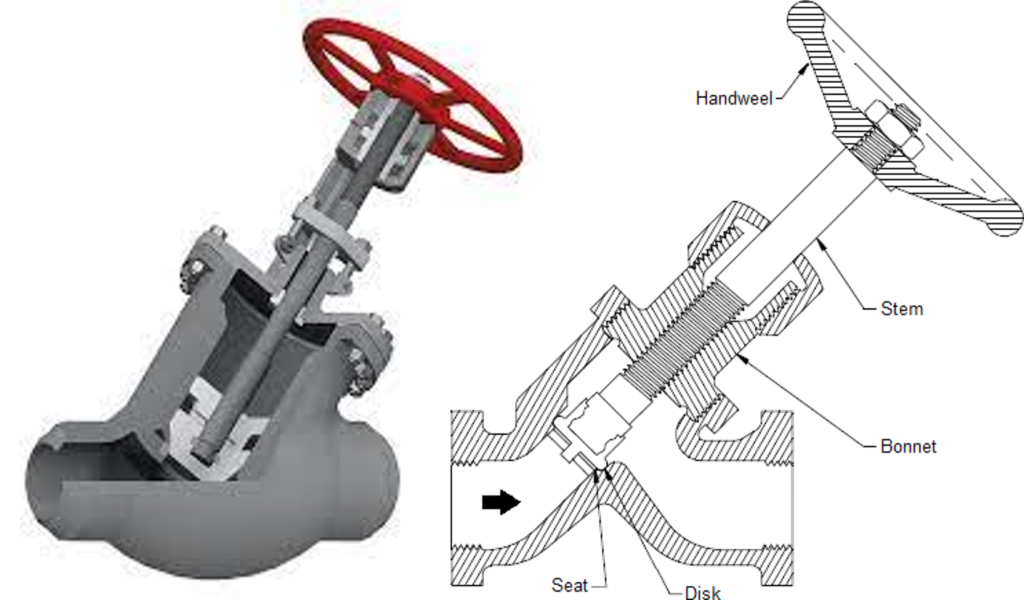

4. Main Components & Their Functions

- Valve Body: The body of the globe valve contains the passage for fluid flow. It is designed to withstand high pressures and temperatures, ensuring the valve’s durability and safety.

- Disc or Plug: This component regulates the flow by opening and closing within the valve body. It is the primary element responsible for controlling the fluid flow rate.

- Stem: The stem connects the actuator to the disc or plug. When the actuator is activated, the stem moves, allowing the disc to lift or press against the seat, thereby controlling the flow.

- Bonnet: The bonnet serves as a cover for the valve body, housing the internal components. It provides a leak-proof seal, preventing fluid from escaping the valve.

- Seat: The seat is a crucial component that ensures proper sealing when the valve is closed. It forms a tight seal with the disc, preventing any leakage.

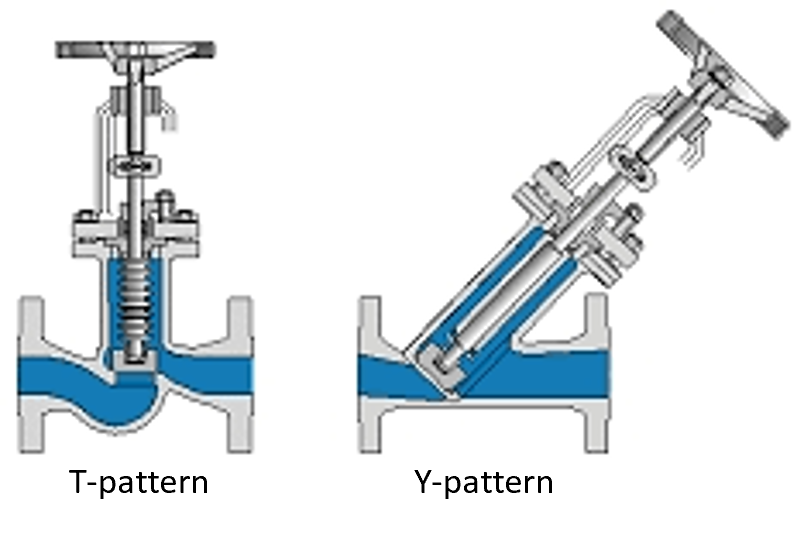

5. Y-pattern Globe Valve vs Straight-pattern Globe Valve

| Criteria | Y-pattern Globe Valve | Straight-pattern Globe Valve |

|---|---|---|

| Flow Path | Y-shaped, minimizes pressure drop and enhances flow | Straight, causes higher pressure drop due to sharp turns |

| Pressure Drop | Lower pressure drop due to streamlined flow path | Higher pressure drop due to abrupt changes in flow direction |

| Flow Control Precision | Highly precise flow control, ideal for throttling | Less precise compared to Y-pattern, better for on-off service |

| Applications | Suitable for applications requiring precise control, such as throttling in various industries | Often used in simpler applications where precise control is not critical |

| Installation | Requires careful alignment for optimal performance | Easier to install due to straight-line flow path |

| Space Efficiency | Requires more space due to the Y-shaped design | More compact design, suitable for tight spaces |

| Maintenance | May require more frequent maintenance due to complex internal structure | Generally easier to maintain due to simpler internal configuration |

6. Application of Y-pattern Globe Valves

Y-pattern globe valves find extensive applications across various industries due to their precision in flow control. In the oil and gas sector, these valves are used to regulate the flow of crude oil and natural gas, ensuring safe and efficient transportation. Water treatment plants utilize globe valves to manage water flow and pressure, essential for providing clean and potable water to communities. In the petrochemical industry, these valves are employed to handle a wide range of chemical fluids and gases. Additionally, Y-pattern globe valves play a vital role in HVAC systems, maintaining optimal temperatures by controlling the flow of heating and cooling fluids.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

7. Advantages & Disadvantages

| Advantages | Disadvantages |

|---|---|

| Precise Flow Control | High Pressure Drop |

| Good Shut-off Capability | Slower Operation |

| Versatility in Applications | Higher Maintenance Requirements |

| Suitable for Throttling Applications | Limited in High-Pressure Systems |

Y-pattern globe valves offer precise flow control, making them ideal for applications where accurate regulation is essential. However, they come with certain limitations, including a relatively high pressure drop and slower operation compared to other valve types. Additionally, their maintenance requirements can be more demanding, especially in applications with corrosive fluids.

8. Associated Codes & Standards

| Codes | Standards |

|---|---|

| ASME B16.34: Valve Flanges and Fittings | API 602: Compact Steel Gate Valves |

| ASME B16.10: Face-to-Face and End-to-End | API 598: Valve Inspection and Testing |

| API 600: Steel Gate Valves – Flanged and Buttwelding Ends | MSS SP-25: Standard Marking System for Valves, Fittings, Flanges and Unions |

| API 603: Corrosion-Resistant, Bolted Bonnet Gate Valves | MSS SP-55: Quality Standard for Steel Castings for Valves, Flanges, Fittings, and Other Piping |

9. Conclusion

In conclusion, Y-pattern globe valves have a rich history and continue to be vital components in numerous industries. Their precise flow control capabilities make them indispensable in applications where accuracy is paramount. Despite certain disadvantages, their advantages far outweigh the limitations, making them a preferred choice for engineers and industries globally. As technology advances, these valves are expected to evolve further, ensuring even more efficient and reliable performance in diverse applications. Understanding their working principles and adhering to relevant codes and standards is essential for harnessing their full potential in various industrial processes.

By delving into the intricacies of Y-pattern globe valves, engineers and professionals can make informed decisions regarding their selection, installation, and maintenance, thereby ensuring the seamless operation of industrial systems across the globe.

FAQs

1. Q: What is the main advantage of using a Y-pattern globe valve over other types of globe valves?

A: The main advantage of a Y-pattern globe valve lies in its streamlined, Y-shaped flow path. This design minimizes pressure drop, making it ideal for applications where pressure loss needs to be minimized, and allows for more precise flow control, especially in throttling applications.

2. Q: What industries commonly use Y-pattern globe valves, and for what specific applications?

A: Y-pattern globe valves find extensive use in industries such as oil and gas, water treatment, petrochemical, and HVAC. They are employed for applications such as regulating the flow of crude oil and natural gas, managing water flow and pressure in treatment plants, handling various chemical fluids and gases, and controlling heating and cooling fluids in HVAC systems.

3. Q: How do Y-pattern globe valves differ from other types of globe valves in terms of construction and internal components?

A: Y-pattern globe valves have a distinct Y-shaped internal configuration, which reduces pressure drop and allows for precise control. In contrast, straight-pattern globe valves have a simpler straight-line flow path, which results in higher pressure drop. The internal components of Y-pattern valves are carefully designed to enable efficient flow control, especially in applications requiring throttling.

4. Q: What are the key considerations for selecting the right Y-pattern globe valve for a specific application?

A: When selecting a Y-pattern globe valve, factors such as the required flow rate, pressure drop tolerance, fluid type, and system pressure and temperature should be considered. Additionally, the material of construction, compatibility with the fluid being handled, and adherence to relevant industry standards and codes play a crucial role in choosing the appropriate valve for a given application.

5. Q: How can Y-pattern globe valves be maintained to ensure optimal performance and longevity?

A: Proper maintenance of Y-pattern globe valves involves regular inspections, lubrication of moving parts, and checking for signs of wear or leakage. Routine testing for proper functioning, especially in throttling applications, is essential. Additionally, following manufacturer-recommended maintenance schedules and promptly addressing any issues that arise can help ensure the longevity and optimal performance of Y-pattern globe valves.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Attempt Quiz

Question 1:

What is the primary purpose of a Y-pattern globe valve?

Explanation: A Y-pattern globe valve is primarily used to control the flow of fluids in pipelines.

Question 2:

What is the shape of the flow path in a Y-pattern globe valve?

Explanation: The flow path in a Y-pattern globe valve is Y-shaped, hence the name.

Question 3:

Which component of a Y-pattern globe valve controls the flow of fluids?

Explanation: The disc or plug, often controlled by the stem, is the component of a Y-pattern globe valve that controls the flow of fluids.

Question 4:

What is the typical application of a Y-pattern globe valve?

Explanation: A typical application of a Y-pattern globe valve is regulating steam flow in a power plant.

Question 5:

What is the advantage of using a Y-pattern globe valve over other valve types?

Explanation: One advantage of using a Y-pattern globe valve is precise flow control.

Question 6:

What material is commonly used for the construction of Y-pattern globe valve bodies?

Explanation: Cast iron or steel is commonly used for the construction of Y-pattern globe valve bodies.

Question 7:

What is the function of the bonnet in a Y-pattern globe valve?

Explanation: The bonnet in a Y-pattern globe valve serves to hold the valve stem.

Question 8:

What is the maximum pressure that a Y-pattern globe valve can typically handle?

Explanation: Y-pattern globe valves can handle high pressures, making them suitable for many industrial applications.

Question 9:

What is the typical temperature range for the operation of Y-pattern globe valves?

Explanation: Y-pattern globe valves can operate in high-temperature environments, making them suitable for various industrial processes.

Question 10:

What is the common industry where Y-pattern globe valves are extensively used?

Explanation: Y-pattern globe valves are extensively used in the oil and gas industry.