Introduction

Pipes are the unsung heroes of modern infrastructure, transporting fluids like water, oil, and gas across industries and homes. But what keeps these conduits functioning efficiently and safely? The answer lies in understanding pipe dimensions and sizes. In this comprehensive guide, we embark on a journey through the intricate world of pipes, from the basics of dimensions to the complexities of calculations, applications, challenges, and future trends. So, let’s dive in and demystify the critical aspects of pipe sizing.

Table of Contents

Do not miss the detailed course on What is Pipe II Schedule II Plastic II Jacketed II Tracing

Enrollment Link

I. Basics of Pipe Dimensions

Nominal Pipe Size (NPS) and Outside Diameter (OD)

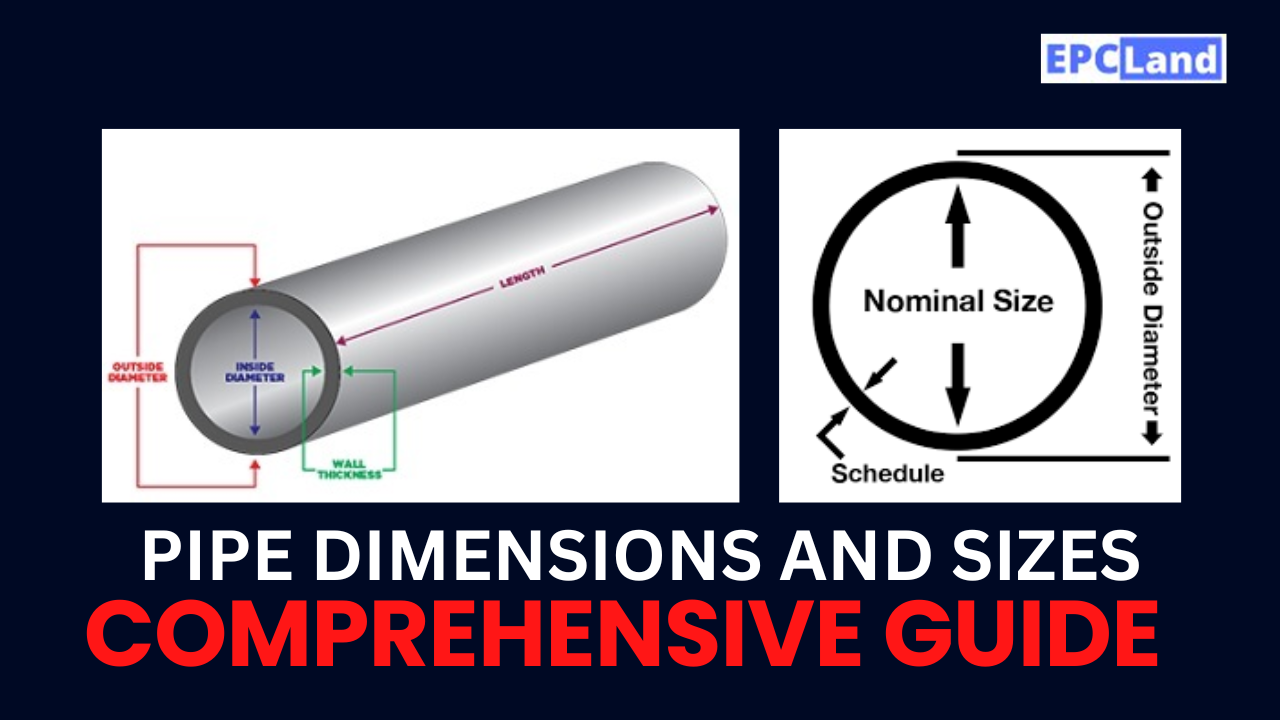

At the heart of pipe dimensions lies the concept of Nominal Pipe Size (NPS). It’s a numerical representation that indicates the approximate inside diameter of the pipe. However, the NPS doesn’t necessarily correspond to the actual pipe dimensions. The true outer measurement is the Outside Diameter (OD), which varies based on the pipe’s schedule (thickness). Understanding the distinction between NPS and OD is fundamental in interpreting pipe sizing specifications.

Wall Thickness and Its Role

Wall thickness is a silent determinant of a pipe’s structural integrity, pressure capacity, and weight. Pipes with thicker walls possess the strength to handle higher pressure loads, rendering them suitable for applications where robustness is paramount. Conversely, pipes with thinner walls are lighter and more cost-effective, but they might have limitations in terms of pressure containment.

Similar Articles related to Pipe

| Topic | Weblink | Topic | Weblink |

|---|---|---|---|

| Pipe Insulation Materials | Link | ASME B36.10 | Link |

| Piping Codes & Standards | Link | Non-Metallic Pipes | Link |

| Pressure-Temperature Ratings | Link | Pipe Standards & Specifications | Link |

| Pipes for Different Fluids | Link | Pipe Coatings & Linings | Link |

| Pipe Materials Selection Guidelines | Link | Corrosion & Pipe Protection | Link |

| High-Temperature Pipes | Link | Pipe Dimensions & Sizes | Link |

| Pipe Manufacturing Processes | Link | Types of Pipes in Piping Systems | Link |

| Pipe Thickness Calculations | Link | Pipe Inspection & Testing | Link |

II. Common Pipe Sizing Standards

ASME B36.10 and ASME B36.19

When it comes to pipe sizing standards, the American Society of Mechanical Engineers (ASME) shines with two prominent standards: B36.10 for welded and seamless wrought steel pipes, and B36.19 for stainless steel pipes. These standards offer meticulous guidelines for dimensions such as NPS, OD, and wall thickness, serving as a beacon for engineers and manufacturers to ensure accurate pipe sizing.

ISO 6708 and API 5L

On the global stage, the International Organization for Standardization (ISO) contributes ISO 6708, a guide to the terms and symbols employed in pipe specifications. In the oil and gas sector, the American Petroleum Institute (API) introduces API 5L, a revered standard for line pipes. API 5L encompasses specifications for both seamless and welded pipes, accentuating material attributes and dimensions.

III. Factors Influencing Pipe Sizing

Fluid Flow Requirements

In the world of pipes, the flow of fluids is paramount. Factors such as the volume, pressure, and velocity of the transported fluid exert significant influence on pipe sizing. Elevated flow rates or pressure requirements necessitate larger pipes to accommodate the increased load. Calculations take into account parameters like the Reynolds number, which determines whether the flow is laminar or turbulent, dictating the selection of pipe diameter.

Material Compatibility

The marriage between the pipe material and sizing is a critical one, profoundly influenced by factors such as corrosion and erosion. Corrosive fluids demand pipes with thicker walls or materials resistant to corrosion to ensure longevity. High-velocity flows induce erosion, necessitating durable materials and precise sizing to stave off premature wear and tear.

Do not miss the detailed course on What is Pipe II Schedule II Plastic II Jacketed II Tracing

Enrollment Link

IV. Types of Pipe Dimensions

Inside Diameter (ID) vs. Outside Diameter (OD)

Distinguishing between Inside Diameter (ID) and Outside Diameter (OD) is pivotal. The Inside Diameter affects flow capacity, determining how much fluid can pass through the pipe. Meanwhile, the Outside Diameter influences the pipe’s structural integrity and weight. Manufacturers provide specifications for both dimensions, empowering engineers to select the appropriate pipe for their intended application.

Wall Thickness and Schedule Number

Wall thickness receives categorization through schedule numbers, such as Sch 40, Sch 80, and so on. These numbers are indicators of the thickness of the pipe’s walls and wield significant influence in determining pressure containment capabilities. Thicker schedules bolster the pipe’s resistance to higher pressures, making them ideal for applications demanding robust performance under stress.

V. Pipe Sizing Calculations

Fluid Properties and Flow Conditions

Akin to a symphony, fluid properties like density and viscosity play melodious roles in the harmony of pipe sizing calculations. Viscous fluids necessitate larger pipes to minimize pressure drop. Flow conditions, whether laminar or turbulent, govern the choice of pipe diameter, thereby influencing pressure loss along the pipe’s length.

Flow Rate Calculations

At the heart of pipe sizing lies the calculation of the required flow rate. Considerations encompass desired flow velocity and the available pressure head. Engineers wield various equations—such as the Hazen-Williams equation or the Darcy-Weisbach equation—to unravel the optimal pipe diameter, ensuring the fluid’s journey is both efficient and effective.

Pressure Drop Considerations

As fluids traverse pipes, friction between the fluid and the pipe walls begets pressure drop, also known as head loss. Engineers must account for pressure drop to ensure the system functions with efficiency. Accurate pipe sizing serves as a mitigating force against pressure drop, safeguarding the desired flow characteristics.

VI. Pipe Sizing in Practice

Plumbing Applications

In the domain of plumbing systems, pipe sizing orchestrates the symphony of water distribution efficiency. An oversized pipe might squander precious water, while an undersized counterpart could orchestrate a symphony of frustrated residents due to diminished water pressure. Precise pipe sizing ensures a harmonious distribution of water flow and consistent pressure throughout residential and commercial spaces.

Oil and Gas Pipelines

In the realm of hydrocarbons, accurate pipe sizing is akin to orchestrating a symphony of energy transport. For oil and gas pipelines spanning vast distances, optimal sizing isn’t just a technicality—it’s an imperative. Deviating from proper sizing can yield energy losses, inefficiencies, and, potentially, safety hazards. API 5L’s comprehensive specifications for line pipes serve as a conductor’s baton, guiding engineers toward harmonious energy transport.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems dance to the rhythm of properly sized pipes. These pipes are conduits of thermal comfort, distributing heated or cooled air to interior spaces. Proper pipe sizing, akin to an astute choreographer, minimizes energy consumption and orchestrates a ballet of consistent indoor comfort levels.

Do not miss the detailed course on What is Pipe II Schedule II Plastic II Jacketed II Tracing

Enrollment Link

VII. Pipe Expansion and Contraction

Effects of Temperature Variations

Temperature fluctuations inject a dynamic note into the world of pipe sizing. As temperatures oscillate, pipes expand and contract, creating the need for precise sizing to prevent issues like buckling or excessive stress. Engineering harmonious pipe systems requires accounting for the thermal fluctuations that could influence the pipes’ dimensions.

Expansion Joints

Enter expansion joints—the virtuoso of pipe systems. These flexible connectors elegantly handle thermal expansion and contraction, ensuring structural harmony in the face of temperature variations. By absorbing the strains of temperature-induced movements, expansion joints preserve mechanical harmony and extend the symphonic lifespan of pipes.

VIII. Standards for Pipe Fittings and Compatibility

Pipe Fittings and Dimensional Consistency

Pipe fittings, akin to musical notes, compose the harmonious union of pipes. These connectors direct fluid flow, enabling the intricate choreography of pipe systems. Their dimensions must harmonize with pipe sizing standards to ensure compatibility. Dissonant fittings could rupture the flow’s melody, introducing leaks and compromising the system’s harmonious resonance.

Adherence to Industry Standards

In the grand orchestra of pipe systems, adherence to industry standards is the conductor’s baton. Employing fittings that align with standards ensures that the performance is harmonious and consistent. Standardized fittings are akin to playing in tune, ensuring that connections are secure, and the system resonates with reliability.

IX. Challenges and Pitfalls

Unexpected Pressure Drops

In the symphony of fluid transport, unexpected pressure drops play the role of discordant notes. Incorrect pipe sizing can give rise to unanticipated pressure drops, resulting in suboptimal flow rates and operational inefficiencies. Engineers must wield their calculative batons adeptly to ensure the symphony maintains its intended rhythm.

Consequences of Incorrect Sizing

Imagine a symphony wherein the instruments play out of tune. Similar dissonance arises when pipes are either undersized or oversized. Undersized pipes labor to meet demand, rendering inadequate flow rates and compromised functionality. Conversely, oversized pipes yield an opulent waste of energy, material, and space, affecting efficiency and financial harmony.

Do not miss the detailed course on What is Pipe II Schedule II Plastic II Jacketed II Tracing

Enrollment Link

X. Tools and Software for Pipe Sizing

Modern Pipe Sizing Tools

In the contemporary era, technological marvels extend their hands to the realm of pipe sizing. Sophisticated software and tools step into the limelight, gracefully accommodating complex fluid dynamics and intricate calculations. These tools, the virtuosi of the digital age, execute calculations with the precision of a maestro, guiding engineers toward the harmonious realm of accurate pipe sizing.

Benefits of Digital Solutions

Embracing digital pipe sizing tools isn’t just a technical choice—it’s a strategic one. These tools amplify speed, accuracy, and versatility. They fluidly navigate complex calculations, enabling engineers to explore myriad scenarios without succumbing to the tedium of manual calculations. Digital solutions are akin to an ensemble of virtuoso performers, breathing life into the technical symphony of pipe sizing.

XI. Future Trends in Pipe Sizing

Integration of AI and Machine Learning

The future of pipe sizing beckons with the allure of artificial intelligence (AI) and machine learning (ML). These technologies act as avant-garde composers, orchestrating predictive models that decipher optimal pipe dimensions. By analyzing historical data, fluid properties, and an array of influencing factors, AI and ML algorithms draft harmonious designs that resonate with unparalleled accuracy.

Simulation and Virtual Prototyping

As we peer into the horizon, the sun rises on the realm of simulation and virtual prototyping. This avant-garde approach thrusts engineers into a virtual concert hall, allowing them to experiment with pipe dimensions within a digital soundscape. Simulating fluid flow, pressure dynamics, and temperature variations, this approach curates a virtual symphony of accurate pipe sizing, minimizing trial and error and orchestrating flawless designs.

Conclusion

In the intricate symphony of pipes, understanding dimensions and sizes is paramount. Accurate pipe sizing governs the harmonious flow of fluids, underpinning efficient and safe operations across industries. From plumbing to oil and gas, from HVAC to advanced manufacturing, proper sizing conducts the performance of each system, orchestrating efficiency, reliability, and cost-effectiveness.

As you traverse the landscape of pipe dimensions, keep in mind that you’re not merely crunching numbers or selecting materials—you’re composing a symphony. Your orchestration of accurate dimensions ensures fluids flow melodiously, pressures are contained harmoniously, and operations resonate seamlessly.

So, whether you’re a seasoned engineer whose fingers dance over calculations like a pianist on keys, or a curious novice eager to learn the rhythm of pipe systems, remember that the journey of understanding pipe dimensions and sizes is a continuous one. By honing your skills, embracing technology’s virtuosity, and harmonizing with evolving trends, you’ll play a pivotal role in the symphony that underpins our modern world’s infrastructure.

Do not miss the detailed course on What is Pipe II Schedule II Plastic II Jacketed II Tracing

Enrollment Link

FAQs

1. What is the significance of Nominal Pipe Size (NPS) in pipe dimensions?

Answer: Nominal Pipe Size (NPS) is a standard used to describe the approximate inside diameter of a pipe. It provides a common reference point for pipe sizing, allowing manufacturers, engineers, and users to communicate effectively about pipe dimensions. However, it’s important to note that NPS doesn’t directly reflect the actual dimensions of the pipe, as the actual outside diameter (OD) and wall thickness can vary based on the pipe’s schedule.

2. How does fluid flow affect pipe sizing decisions?

Answer: Fluid flow requirements have a substantial impact on pipe sizing decisions. Factors such as flow rate, pressure, and fluid velocity influence the choice of pipe diameter. Higher flow rates or pressure requirements often necessitate larger pipes to accommodate the increased load and prevent excessive pressure drops. Calculations involving Reynolds numbers help engineers determine whether the flow will be laminar or turbulent, which, in turn, guides the selection of the appropriate pipe diameter.

3. What role does material compatibility play in pipe sizing?

Answer: Material compatibility is a critical consideration in pipe sizing due to factors like corrosion and erosion. Corrosive fluids can lead to pipe degradation over time, necessitating pipes with thicker walls or corrosion-resistant materials. Similarly, high-velocity flows can cause erosion, which requires durable materials and proper sizing to prevent premature wear and tear. Selecting the right material and sizing ensures the longevity and safety of the piping system.

4. How does wall thickness impact pipe sizing?

Answer: Wall thickness is a fundamental component of pipe sizing, directly affecting a pipe’s strength, pressure capacity, and weight. Thicker-walled pipes are capable of handling higher pressure loads, making them suitable for applications that demand durability. Thinner-walled pipes are lighter and more cost-effective but may have limitations in terms of pressure containment. Engineers must balance these considerations based on the specific requirements of the system.

5. What are the advantages of using modern pipe sizing tools and software?

Answer: Modern pipe sizing tools and software offer numerous advantages. These digital solutions leverage complex fluid dynamics and calculations to provide accurate sizing recommendations quickly. They enable engineers to explore various scenarios, optimizing pipe dimensions for efficiency and performance. These tools enhance accuracy, reduce human error, and expedite the design process, making them indispensable in complex piping systems, where precision and optimization are paramount.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What is the standard unit of measurement for pipe dimensions?

Explanation: The standard unit of measurement for pipe dimensions is inches, which is commonly used to specify the nominal size and wall thickness of pipes.

Question 2:

What does “Nominal Pipe Size” (NPS) refer to?

Explanation: “Nominal Pipe Size” (NPS) refers to a standardized designation used to indicate the approximate inside diameter of a pipe, although it is not an exact measurement of the actual diameter.

Question 3:

What is the purpose of “Schedule” in pipe dimensions?

Explanation: “Schedule” in pipe dimensions refers to a standardized system that indicates the wall thickness of pipes. It helps ensure compatibility between pipes and fittings.

Question 4:

What is the relationship between NPS and actual pipe dimensions?

Explanation: NPS is larger than the actual inside diameter of the pipe due to the inclusion of wall thickness. The relationship between NPS and actual dimensions varies based on the pipe’s schedule.

Question 5:

What does “Outside Diameter” (OD) refer to in pipe dimensions?

Explanation: “Outside Diameter” (OD) refers to the diameter of the pipe measured from the outer edge of the pipe. It is an important dimension used in various pipe applications.