1. Introduction

Concentric butterfly valves are vital components in various industrial processes, regulating the flow of fluids with precision and efficiency. Unlike their predecessors, these valves have undergone significant advancements, making them indispensable in diverse sectors. This article delves into the intricate world of concentric butterfly valves, exploring their history, functionality, components, applications, advantages, disadvantages, and adherence to standards.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

2. Brief History

The concept of butterfly valves dates back to ancient times when engineers and inventors sought ingenious ways to control fluid flow. The earliest versions were rudimentary, lacking the precision and efficiency of modern designs. It wasn’t until the industrial revolution that significant strides were made in valve technology. The concentric butterfly valve, characterized by a disk rotating on an axis perpendicular to the flow, emerged as a breakthrough.

3. Basic Function and Working Principle

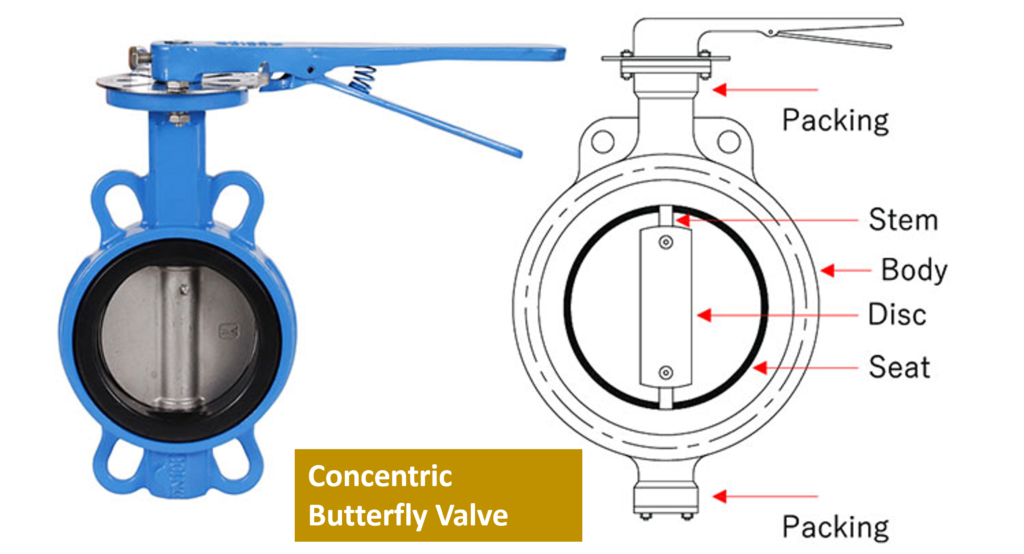

Butterfly valves operate on a simple yet effective principle. A flat circular plate, known as the disc, is positioned in the center of the pipe. When the valve is open, the disc is turned parallel to the flow, allowing unrestricted passage for fluids. Conversely, when the valve is closed, the disc is rotated perpendicular to the flow, obstructing the passage of fluids. This ingenious design ensures quick and efficient flow control, making these valves ideal for various applications.

4. Main Components & Its Function

Understanding the components of a concentric butterfly valve is crucial for appreciating its functionality. The primary components include the valve body, disc, stem, seat, and actuator. The valve body provides the housing for other components, while the disc, attached to the stem, controls the flow. The seat forms a seal around the disc, preventing leakage. The actuator, which can be manual, electric, or pneumatic, facilitates the movement of the disc. Each component plays a vital role in ensuring smooth operation and reliability.

5. Application of Concentric Butterfly Valves

Concentric butterfly valves find applications across a wide range of industries due to their versatility and efficiency. They are commonly used in water treatment plants, HVAC systems, chemical processing, and food and beverage production. In water treatment plants, these valves regulate the flow of water and chemicals, ensuring precise mixing and distribution. In HVAC systems, they control the passage of air and water, maintaining optimal temperatures. Additionally, their corrosion-resistant materials make them ideal for chemical processing, where exposure to harsh chemicals is common.

6. Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Low pressure drop | Limited in high-pressure applications |

| Compact and lightweight | Prone to cavitation |

| Quick operation | Limited throttling capability |

| Cost-effective | |

| Low maintenance |

Concentric butterfly valves offer several advantages. Their low pressure drop minimizes energy loss, making them energy-efficient choices. Moreover, their compact and lightweight design simplifies installation and reduces the overall weight of the system. Quick operation ensures rapid response to changing flow requirements, enhancing process efficiency. From a financial perspective, these valves are cost-effective, both in terms of initial investment and long-term maintenance. However, they do have limitations, particularly in high-pressure applications where their structural integrity might be compromised. Additionally, they are susceptible to cavitation, a phenomenon where rapid changes in fluid pressure create vapor bubbles that can damage the valve. Furthermore, their limited throttling capability makes them unsuitable for applications requiring precise flow control.

7. Concentric Butterfly Valves in Practice

To illustrate the practicality of concentric butterfly valves, consider their application in a municipal water treatment plant. In this scenario, these valves play a pivotal role in regulating the flow of water and chemicals. The valve’s quick response to changes in flow requirements ensures optimal mixing of chemicals, maintaining the water’s quality. Additionally, their low maintenance requirements translate to reduced downtime and operational costs, making them the preferred choice for such critical applications.

8. Associated Codes & Standards

| Standard | Description |

|---|---|

| API 609 | Standard for butterfly valves: Double-flanged, lug, wafer |

| ASME B16.34 | Valves – Flanged, Threaded, and Welding End |

| AWWA C504 | Rubber-Seated Butterfly Valves |

| ISO 5752-20 | Metal valves for use in flanged pipe systems – Part 20 |

Concentric butterfly valves adhere to various industry standards to ensure their quality and reliability. API 609 provides specifications for different types of butterfly valves, including double-flanged, lug, and wafer designs. ASME B16.34 outlines the standards for flanged, threaded, and welding end valves, ensuring compatibility with different piping systems. AWWA C504 specifically focuses on rubber-seated butterfly valves, emphasizing the importance of proper sealing mechanisms. Furthermore, ISO 5752-20 provides guidelines for metal valves used in flanged pipe systems, guaranteeing their performance and longevity.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

9. Concentric Butterfly Valve vs Eccentric Butterfly Valve

| Aspect | Concentric Butterfly Valve | Eccentric Butterfly Valve |

|---|---|---|

| Disk Offset | No offset, disk centered within the pipe bore | Offset, disk is positioned away from the center |

| Sealing | More vulnerable to wear due to central position | Better sealing due to eccentric design |

| Flow Performance | Lower pressure drop, ideal for low-pressure systems | Higher pressure drop, suitable for high-pressure applications |

| Torque Requirement | Lower torque required for operation | Higher torque needed due to offset disk |

| Applications | Wide range of general applications | Suitable for applications requiring tight shut-off |

| Cost | Generally more cost-effective | Higher cost due to complex design and materials |

| Maintenance | Easier maintenance due to simpler design | Requires more maintenance due to offset and wear |

| Installation | Easier to install due to straightforward design | More complex installation due to offset and size |

| Cavitation Resistance | More susceptible to cavitation in high-velocity applications | Better resistance to cavitation in specific applications |

| Throttling Capability | Limited throttling capability due to design | Better throttling capability due to eccentricity |

| Common Industries | HVAC, water treatment, general industrial usage | Oil & gas, chemical processing, high-pressure systems |

10. Future Trends and Innovations

The future of concentric butterfly valves is marked by continuous innovation and integration with digital technologies. Internet of Things (IoT) capabilities are being incorporated into these valves, allowing real-time monitoring and remote control. Predictive maintenance algorithms, powered by artificial intelligence, enable proactive identification of potential issues, minimizing downtime and enhancing reliability. Additionally, advancements in materials and manufacturing techniques are paving the way for valves capable of withstanding extreme conditions, expanding their applicability in diverse industries.

11. Conclusion

Concentric butterfly valves have come a long way since their inception, evolving into indispensable components in various industrial processes. Their efficient functionality, coupled with advancements in materials and technology, ensures their relevance in the ever-changing landscape of industrial applications. By adhering to stringent standards and embracing emerging technologies, these valves continue to play a pivotal role in regulating fluid flow, contributing significantly to the efficiency and reliability of industrial systems.

FAQs

1. What are Concentric Butterfly Valves and How Do They Differ from Other Valve Types?

Concentric butterfly valves are devices used to regulate the flow of fluids in various industrial applications. Unlike other valves, their design involves a flat circular plate, or disc, positioned in the center of the pipe, allowing for efficient control of fluid flow. Understanding their unique design and operation is crucial for selecting the right valve for specific applications.

2. What Are the Key Advantages of Using Concentric Butterfly Valves in Industrial Systems?

Concentric butterfly valves offer several advantages, including low pressure drop, compact design, quick operation, cost-effectiveness, and low maintenance requirements. These features make them popular choices in industries where efficient flow control is essential. Exploring these advantages in detail helps businesses understand why these valves are preferred in various applications.

3. What Are the Limitations of Concentric Butterfly Valves, and How Can These Challenges Be Mitigated?

While concentric butterfly valves have numerous advantages, they also come with limitations, such as susceptibility to cavitation and limited use in high-pressure applications. Understanding these limitations is vital for mitigating potential challenges. Exploring techniques and technologies to overcome these limitations ensures the optimal performance and longevity of these valves in diverse industrial settings.

4. How Are Concentric Butterfly Valves Integrated with Modern Technologies, Such as IoT and Artificial Intelligence?

In recent years, concentric butterfly valves have been integrated with modern technologies like the Internet of Things (IoT) and artificial intelligence (AI). These integrations allow for real-time monitoring, remote control, and predictive maintenance, enhancing the efficiency and reliability of industrial processes. Exploring these advancements provides insights into the future of valve technology and its impact on industrial automation.

5. What Standards and Regulations Govern the Manufacturing and Use of Concentric Butterfly Valves, and Why Are They Important?

Concentric butterfly valves must adhere to specific industry standards and regulations to ensure their quality, reliability, and safety. Understanding the standards, such as API 609, ASME B16.34, AWWA C504, and ISO 5752-20, is crucial for manufacturers, engineers, and operators. Exploring the significance of compliance with these standards provides clarity on the importance of maintaining high-quality valve systems in industrial applications.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Attempt Quiz

Question 1:

What is the primary function of a concentric butterfly valve?

Explanation: Concentric butterfly valves are primarily used for isolating or regulating the flow of fluids in pipelines.

Question 2:

What is the disc of a concentric butterfly valve made of?

Explanation: The disc of a concentric butterfly valve can be made of metal or plastic, depending on the specific application requirements.

Question 3:

What is the advantage of a concentric butterfly valve over other valve types?

Explanation: Concentric butterfly valves are advantageous due to their low cost, suitability for high-pressure applications, and compact design.

Question 4:

Which type of fluid is a concentric butterfly valve NOT suitable for?

Explanation: Concentric butterfly valves are not suitable for handling abrasive fluids due to potential damage to the valve components.

Question 5:

How does a concentric butterfly valve operate?

Explanation: A concentric butterfly valve operates by rotating the disc 90 degrees to control the flow of fluids.

Question 6:

What is the sealing material used in concentric butterfly valves?

Explanation: The sealing material used in concentric butterfly valves is often rubber, providing effective sealing and preventing leaks.

Question 7:

Which factor determines the flow capacity of a concentric butterfly valve?

Explanation: The flow capacity of a concentric butterfly valve is determined by the size and shape of the disc.

Question 8:

What is the most common application of concentric butterfly valves?

Explanation: Concentric butterfly valves are commonly used in water and wastewater treatment applications.

Question 9:

What is the advantage of a concentric butterfly valve’s compact design?

Explanation: The compact design of concentric butterfly valves requires less space, making them advantageous in installations with limited space.

Question 10:

What should be considered when selecting a concentric butterfly valve for a specific application?

Explanation: When selecting a concentric butterfly valve, it is essential to consider factors such as size, pressure rating, and material compatibility to ensure it meets the specific application requirements.