1. Introduction

Diaphragm valves are indispensable components in various industries, serving as crucial elements in fluid control systems. Unlike conventional valves, diaphragm valves offer unique advantages, making them ideal choices for applications requiring precise flow control, resistance to corrosive substances, and handling of abrasive media. This comprehensive guide delves into the intricate world of diaphragm valves, exploring their history, fundamental principles, types, applications, advantages, and associated codes and standards.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

2. Brief History

The origins of diaphragm valves can be traced back to ancient civilizations, where rudimentary forms of these valves were used to control the flow of water and other liquids. However, the modern diaphragm valve, as we recognize it today, has undergone significant advancements over the centuries. In the mid-20th century, with the rise of industrialization, diaphragm valves became more sophisticated, incorporating innovative materials and designs to meet the demands of various industries.

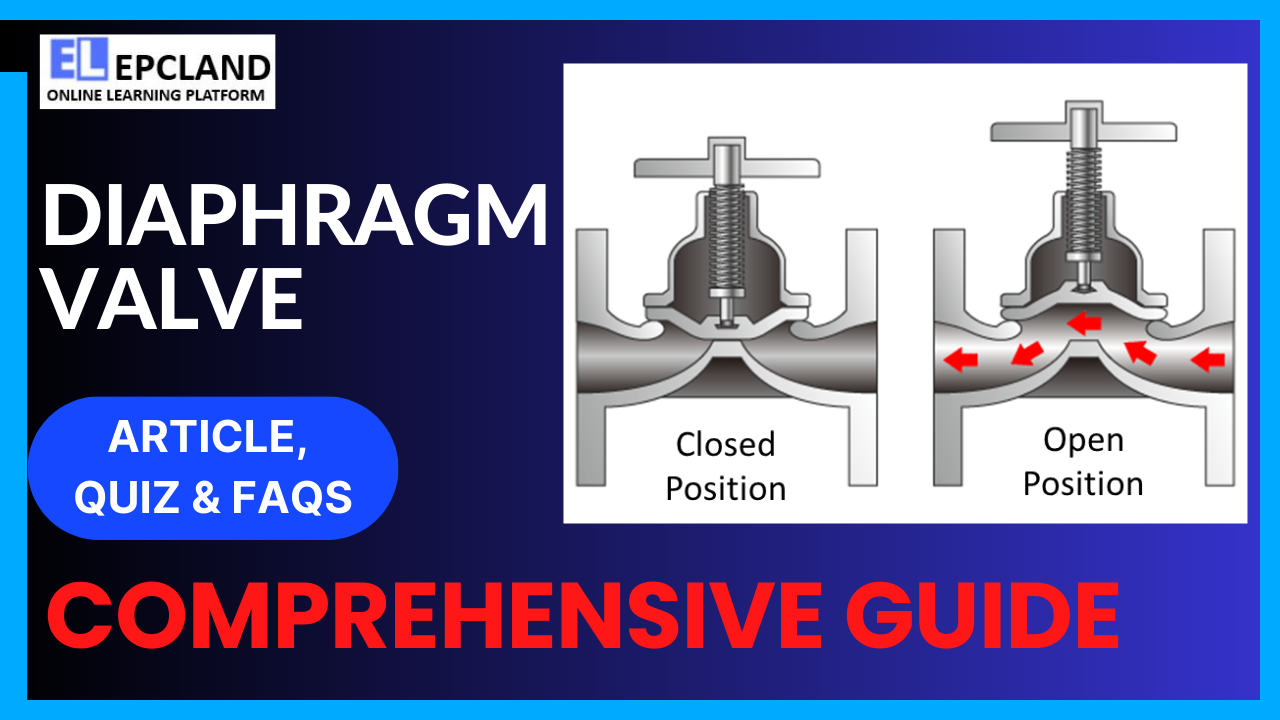

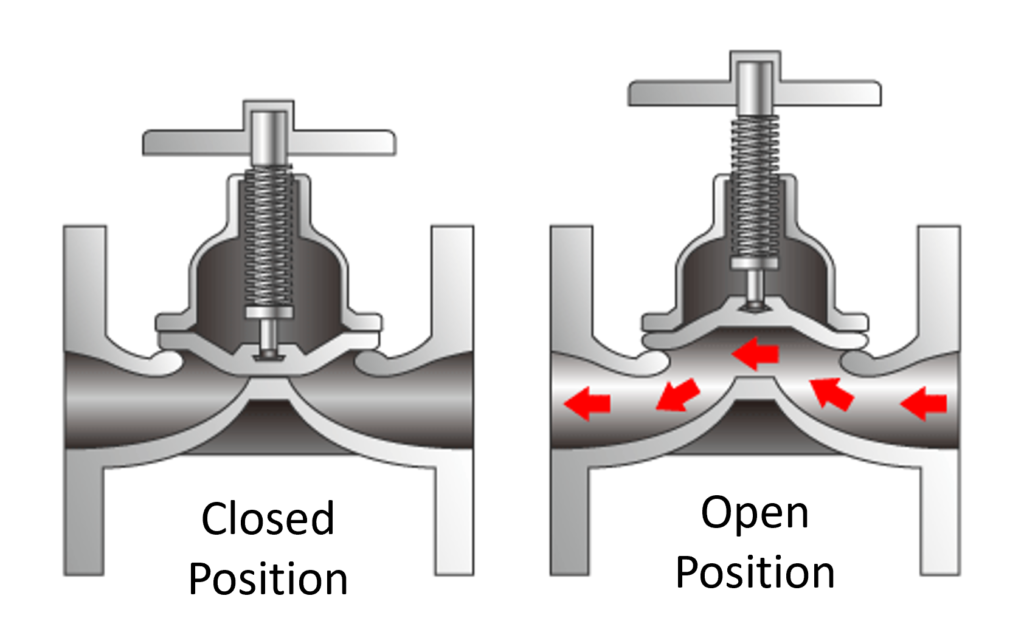

3. Basic Function and Working Principle

Diaphragm valves operate based on a straightforward yet effective principle. The valve consists of a flexible diaphragm, which, when actuated, either allows or restricts the flow of the fluid. This movement of the diaphragm is controlled by an actuator, which can be manual, pneumatic, or electric. When the diaphragm is pressed against the valve seat, it stops the flow. Conversely, releasing the pressure on the diaphragm permits the fluid to pass through the valve.

Compared to traditional valves, diaphragm valves offer superior control over the flow rate due to the direct correlation between the position of the diaphragm and the flow passage. This unique characteristic makes diaphragm valves highly desirable in applications where precise regulation of flow is essential.

4. Main Components

Diaphragm valves consist of several key components, each playing a crucial role in their operation:

- Diaphragm: Typically made of rubber, elastomers, or other flexible materials, the diaphragm is the central component that moves to control the flow of the fluid.

- Body: The body of the valve provides structural support and houses the diaphragm. It is constructed using materials compatible with the fluid being handled and the operating conditions.

- Actuator: The actuator is responsible for moving the diaphragm. Manual valves are operated by hand, while pneumatic and electric valves utilize compressed air or electricity, respectively, to actuate the diaphragm.

- Supporting Components: These include seals, nuts, bolts, and other fastening elements that ensure the valve remains leak-proof and functions efficiently.

5. Types of Diaphragm Valves

Diaphragm valves come in various types, each designed to cater to specific applications:

- Weir Type Diaphragm Valves: These valves have a raised weir around the valve seat, allowing for better control of the flow, especially in applications where slurries or viscous fluids are involved.

- Straightway Type Diaphragm Valves: Straightway valves have a simple linear flow path, making them suitable for applications requiring unobstructed flow without significant pressure drops.

- Two-Way and Three-Way Diaphragm Valves: Two-way valves control the flow between two points, whereas three-way valves can divert the flow between three different paths, offering enhanced versatility.

- Pinch Valves: Pinch valves use a flexible diaphragm, pinched by a mechanism to control the flow. They are particularly useful in applications involving slurries and corrosive media.

6. Applications of Diaphragm Valves

Diaphragm valves find extensive applications across diverse industries due to their unique characteristics:

- Pharmaceutical Industry: Diaphragm valves play a vital role in the pharmaceutical sector, where maintaining sterile conditions is paramount. They are used for controlling the flow of various liquids and gases in drug manufacturing processes.

- Water Treatment: Diaphragm valves are integral to water treatment plants, where they are used to handle corrosive chemicals and control sludge flow. Their resistance to chemical corrosion makes them ideal for such applications.

- Chemical Industry: In the chemical industry, diaphragm valves are employed for handling corrosive and abrasive fluids. Their ability to withstand aggressive chemicals and abrasive media makes them indispensable in chemical processing plants.

- Food and Beverage Industry: Diaphragm valves are widely used in the food and beverage industry for hygienic applications. They are employed in processes such as bottling, brewing, and dairy production, where maintaining sanitary conditions is crucial.

- Other Industries: Diaphragm valves also find applications in mining, oil, and gas industries, where they are used for controlling the flow of abrasive slurries and corrosive substances.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

7. Advantages & Disadvantages

Diaphragm valves offer several advantages, making them preferred choices in various industrial applications. However, they also have limitations that need to be considered:

| Advantages | Disadvantages |

|---|---|

| Resistant to corrosive substances | Limited in high-pressure applications |

| Precise flow control | Diaphragm wear over time |

| Minimal maintenance required | Limited temperature and pressure range |

| Suitable for abrasive media | Initial installation cost might be high |

| Easy to clean and sterilize (for some) | Limited in size for large-scale operations |

8. Associated Codes & Standards

Diaphragm valves are governed by specific codes and standards to ensure their quality, performance, and safety. Some of the notable codes and standards include:

- API 599: This standard covers Metal Plug, and Seat, and Ball Valves for Industrial Applications, providing guidelines for the design and manufacturing of these valves.

- ASME B16.34: ASME B16.34 outlines the requirements for Valves-Flanged, Threaded, and Welding End, ensuring the compatibility and interchangeability of various valve components.

- ISO 9001: ISO 9001 sets the standards for Quality Management Systems, emphasizing the importance of quality control and continuous improvement in valve manufacturing processes.

- ASTM D4895: ASTM D4895 is a standard test method for determining the percentage of air retained by a plaster, ensuring the integrity and quality of diaphragm valve components.

9. Conclusion

In conclusion, diaphragm valves have revolutionized fluid control systems across diverse industries. Their unique design, precise control capabilities, and resistance to corrosive and abrasive media make them indispensable in applications where other valves might fall short. As technology continues to advance, diaphragm valves are likely to see further innovations, leading to even more efficient and reliable fluid control solutions. Understanding their principles, types, applications, advantages, and associated codes and standards is essential for engineers, technicians, and professionals working in fluid control and process industries. By harnessing the power of diaphragm valves, industries can achieve greater efficiency, safety, and reliability in their operations, ensuring the seamless flow of fluids in various processes.

FAQs

1. What distinguishes diaphragm valves from other types of valves, and what are their primary advantages in industrial applications?

Diaphragm valves are unique in their design, featuring a flexible diaphragm that controls the flow of fluids. Unlike traditional valves, they offer precise flow control, resistance to corrosive substances, and the ability to handle abrasive media. These qualities make them highly desirable in industries where accurate flow regulation is essential, such as pharmaceuticals, chemicals, and water treatment.

2. What are the key considerations for selecting the appropriate diaphragm valve for a specific application?

Selecting the right diaphragm valve involves evaluating factors such as the nature of the fluid being handled, pressure and temperature requirements, flow rate, and the presence of corrosive or abrasive elements. Additionally, understanding the specific needs of the industry, such as hygienic standards in the food and beverage sector, is crucial in making an informed choice.

3. How are diaphragm valves maintained, and what are the common issues that might arise during their operational lifespan?

Diaphragm valves are relatively low maintenance, but regular inspections are essential to ensure their proper functioning. Common issues include wear and tear of the diaphragm, which might affect its flexibility, leading to leakage. Additionally, accumulation of debris or corrosion can hinder the valve’s performance. Routine checks and timely replacements are vital to prevent these issues.

4. What role do diaphragm valves play in ensuring the safety and efficiency of industrial processes, especially in applications involving hazardous chemicals or sterile environments?

In industries dealing with hazardous chemicals, diaphragm valves act as crucial safety components. Their resistance to corrosive substances prevents leaks, ensuring the safety of both personnel and the surrounding environment. In sterile environments, such as pharmaceutical cleanrooms, diaphragm valves maintain the necessary hygienic conditions, preventing contamination and ensuring the integrity of the products being processed.

5. How are diaphragm valves evolving with advancements in technology, and what can we expect in terms of future innovations in this field?

As technology continues to advance, diaphragm valves are likely to benefit from innovations in materials, design, and actuation systems. Miniaturization and the integration of smart technologies, such as sensors and automation, might enhance their efficiency and precision further. Additionally, research into new materials that offer superior resistance to extreme conditions could expand the applications of diaphragm valves in industries with demanding environments.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Related Video

Attempt Quiz

Question 1:

What is the primary function of a diaphragm valve?

Explanation: Diaphragm valves are primarily used to regulate fluid flow by opening, closing, or throttling the passage through the valve.

Question 2:

What is the main advantage of diaphragm valves in handling corrosive fluids?

Explanation: Diaphragm valves are advantageous in handling corrosive fluids because they are resistant to corrosion, ensuring the integrity of the valve even with aggressive substances.

Question 3:

Which material is commonly used for diaphragms in diaphragm valves?

Explanation: Diaphragms in diaphragm valves are commonly made of rubber due to its flexibility and resistance to various chemicals.

Question 4:

What is the function of the diaphragm in a diaphragm valve?

Explanation: The diaphragm in a diaphragm valve isolates the valve body from the fluid, preventing contact between the fluid and the valve components.

Question 5:

Which industry commonly uses diaphragm valves for controlling various fluids?

Explanation: Diaphragm valves are commonly used in the pharmaceutical industry for controlling various fluids due to their corrosion resistance and ability to maintain purity.

Question 6:

What is the typical actuation method for diaphragm valves?

Explanation: Diaphragm valves are typically actuated using pneumatic or electric methods for precise and automated control.

Question 7:

What is the advantage of weir-type diaphragm valves?

Explanation: Weir-type diaphragm valves provide better flow control due to their design, making them advantageous in various applications.

Question 8:

What is the main limitation of diaphragm valves?

Explanation: Diaphragm valves have a limited temperature range, which can be a limitation in applications requiring extreme temperature conditions.

Question 9:

Which of the following industries commonly uses diaphragm valves for precise control?

Explanation: The food and beverage industry commonly uses diaphragm valves for precise control of fluids, ensuring accuracy in the production process.

Question 10:

What is the primary benefit of diaphragm valves in pharmaceutical applications?

Explanation: Diaphragm valves in pharmaceutical applications help maintain product purity by preventing contamination, ensuring the quality and safety of pharmaceutical products.