I. Introduction to Double Pipe Heat Exchangers

Table of Contents

Similar Articles on other Exchangers

| Heat Exchanger Type | Check Article Link |

|---|---|

| Helical Coil Heat Exchanger | Link |

| Tube-in-Tube Heat Exchanger | Link |

| Spiral Heat Exchanger | Link |

| U-Tube Heat Exchanger | Link |

| Shell and Tube Heat Exchanger | Link |

| Plate Heat Exchanger | Link |

| Double Pipe Heat Exchanger | Link |

| Finned Tube Heat Exchanger | Link |

Don’t miss the Complete Course on Piping Engineering: Check Now

By EPCLand.com

A. Brief Overview of Heat Exchangers and Their Importance

Heat exchangers play a vital role in various industries by facilitating the efficient transfer of thermal energy between two fluids while keeping them physically separated. This process is essential for processes like heating, cooling, and condensation in industries such as chemical processing, power generation, HVAC systems, and more. Heat exchangers improve energy efficiency, reduce operating costs, and promote sustainable practices by recovering waste heat and optimizing temperature management.

B. Introduction to Double Pipe Heat Exchangers as a Specific Type

Among the diverse types of heat exchangers, the double pipe heat exchanger stands out for its simplicity and versatility. It consists of two concentric pipes or tubes, one within the other, through which the hot and cold fluids flow. This design provides a compact structure that is relatively easy to manufacture, install, and maintain. The simplicity of the double pipe heat exchanger design makes it suitable for various applications, especially when space and cost considerations are important factors.

C. Importance of Studying Double Pipe Heat Exchangers and Their Applications

Studying double pipe heat exchangers is crucial due to their widespread use and the potential for optimizing heat transfer processes. Understanding their working principles, design considerations, and performance characteristics can lead to more efficient industrial operations and improved energy conservation. Engineers and researchers strive to enhance the performance of double pipe heat exchangers by exploring different materials, flow arrangements, and operational strategies. By delving into the intricacies of double pipe heat exchangers, we can uncover opportunities for innovation and contribute to the advancement of heat exchanger technology.

In the following sections of the article, we will delve deeper into the various aspects of double pipe heat exchangers, including their design, heat transfer principles, applications, challenges, recent developments, and future trends. By exploring these topics, we aim to provide a comprehensive understanding of double pipe heat exchangers and their significance in the field of thermal engineering.

II. Types of Heat Exchangers

A. Classification Based on Design and Construction

Heat exchangers come in various designs and configurations to suit different applications. They are typically classified into several categories based on their design and construction. These categories include shell-and-tube heat exchangers, plate heat exchangers, and finned-tube heat exchangers, among others. Each type has its own advantages, disadvantages, and ideal use cases.

B. Overview of Shell-and-Tube Heat Exchangers, Plate Heat Exchangers, and Finned-Tube Heat Exchangers

1. Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchangers are among the most common and widely used types. They consist of a shell (a large outer vessel) with a bundle of tubes inside. One fluid flows through the tubes, while the other flows around them in the shell. This design allows for efficient heat transfer and is suitable for high-pressure and high-temperature applications.

2. Plate Heat Exchangers

Plate heat exchangers use a series of corrugated plates to create a series of channels through which the hot and cold fluids flow. These plates maximize the surface area available for heat transfer, making them compact and efficient. Plate heat exchangers are commonly used in applications where space is limited, and close temperature approaches are required.

3. Finned-Tube Heat Exchangers

Finned-tube heat exchangers have tubes with extended surfaces (fins) attached to them. These fins increase the heat transfer surface area, which enhances heat exchange efficiency. Finned-tube heat exchangers are often used in air-cooling applications, such as in HVAC systems and radiators.

C. Focus on the Working Principle and Advantages of Double Pipe Heat Exchangers

Amidst the various types of heat exchangers, double pipe heat exchangers stand out for their simplicity and ease of design. The concept of having two pipes, one within the other, allows for efficient heat transfer between fluids. This section will further explore the working principles of double pipe heat exchangers and delve into the advantages they offer in terms of design simplicity, versatility, and cost-effectiveness.

In the subsequent sections, we will delve deeper into the design and components of double pipe heat exchangers, the heat transfer principles they rely on, their performance evaluation, applications in various industries, and more. By comprehensively studying these aspects, we aim to provide a comprehensive understanding of the role and significance of double pipe heat exchangers in the field of heat transfer and thermal management.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

III. Double Pipe Heat Exchanger Design and Components

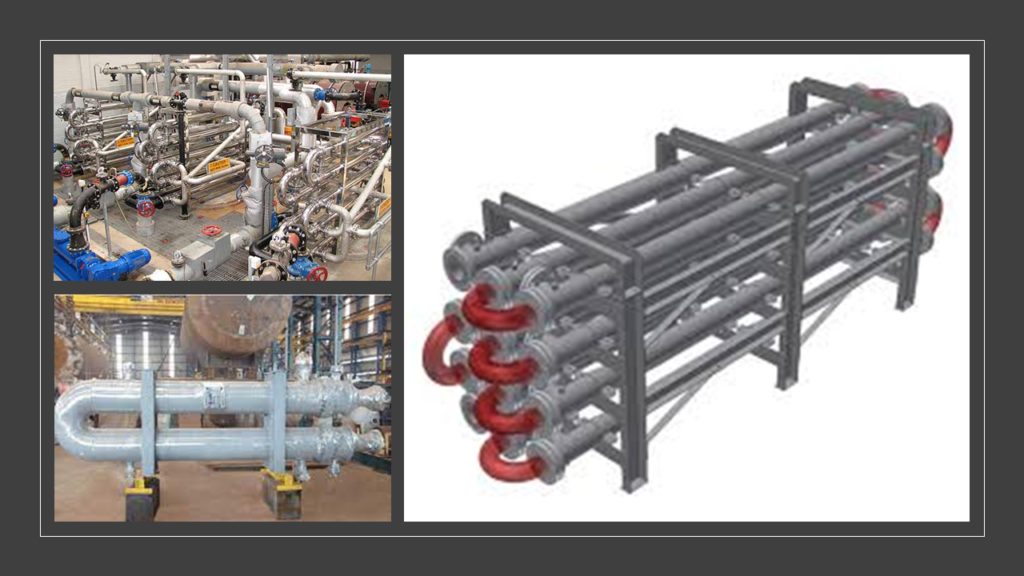

A. Basic Components and Structure of a Double Pipe Heat Exchanger

A double pipe heat exchanger consists of straightforward components that contribute to its efficient heat transfer capabilities. The primary components include an inner tube, an outer shell, inlet and outlet ports for both hot and cold fluids, and appropriate fittings for connections. The simplicity of the design makes it easy to fabricate, install, and maintain, which is particularly advantageous for various industrial applications.

B. Inner and Outer Pipe Arrangements and Configurations

The inner and outer pipes of a double pipe heat exchanger can be arranged in different configurations depending on the heat transfer requirements. Common arrangements include concentric tubes, where one pipe is nested inside the other, and eccentric tubes, where the inner tube is positioned off-center within the outer tube. These arrangements impact factors such as heat transfer efficiency and pressure drop.

C. Types of Flow Arrangements: Parallel Flow, Counterflow, and Crossflow

In double pipe heat exchangers, the flow paths of the hot and cold fluids determine the overall heat transfer efficiency. There are three main flow arrangements: parallel flow, counterflow, and crossflow. Parallel flow involves both fluids moving in the same direction, counterflow involves fluids moving in opposite directions, and crossflow involves fluids moving perpendicular to each other. Each arrangement has its advantages and limitations in terms of heat transfer effectiveness.

D. Materials Used in Double Pipe Heat Exchanger Construction

The choice of materials for constructing double pipe heat exchangers depends on factors such as the nature of the fluids being exchanged, temperature, pressure, and corrosion resistance requirements. Common materials include stainless steel, carbon steel, copper, and various alloys. Proper material selection ensures longevity, performance, and safety in diverse operational conditions.

In the upcoming sections, we will delve into the heat transfer principles that underlie the operation of double pipe heat exchangers, methods for evaluating their performance, applications in different industries, and the challenges associated with their maintenance and operation. By understanding the core design components and considerations, we can gain insights into how double pipe heat exchangers contribute to efficient heat transfer processes.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

IV. Heat Transfer Principles in Double Pipe Heat Exchangers

A. Conduction, Convection, and Radiation: Fundamental Heat Transfer Modes

Heat transfer in double pipe heat exchangers relies on three fundamental modes: conduction, convection, and radiation. Conduction is the transfer of heat through direct contact between solids. Convection involves the transfer of heat through the movement of fluids. Radiation is the transfer of heat through electromagnetic waves. Each mode contributes to the overall heat transfer process within the heat exchanger.

B. Analysis of Heat Transfer Mechanisms Within Double Pipe Heat Exchangers

The design of double pipe heat exchangers promotes efficient heat transfer by creating a large surface area for interaction between the hot and cold fluids. The temperature difference between the fluids drives the heat transfer process. Hot fluid loses heat as it flows through the inner pipe, while cold fluid gains heat as it flows through the outer pipe. This temperature gradient enables the exchange of thermal energy between the fluids.

C. Heat Transfer Equations and Calculations for Different Flow Arrangements

The efficiency of double pipe heat exchangers can be quantified using various heat transfer equations and calculations. For parallel flow, counterflow, and crossflow arrangements, different equations are used to determine parameters such as the heat transfer rate, overall heat transfer coefficient, and temperature profiles. These calculations play a crucial role in designing and optimizing the performance of the heat exchanger.

In the following sections, we will explore methods for evaluating the performance of double pipe heat exchangers using concepts like the logarithmic mean temperature difference (LMTD) method and the effectiveness-NTU (Number of Transfer Units) method. These methods provide valuable insights into the efficiency of heat transfer processes and help engineers make informed decisions regarding heat exchanger design and operation.

V. Performance Evaluation and Analysis

A. Overall Heat Transfer Coefficient (U) and Its Significance

The overall heat transfer coefficient (U) is a critical parameter in assessing the performance of double pipe heat exchangers. U represents the rate of heat transfer per unit area of the heat exchanger’s surface and accounts for all modes of heat transfer. It considers factors like the thermal conductivities of the materials, the fluid properties, and the heat exchanger’s design. A higher U value indicates more efficient heat transfer.

B. Logarithmic Mean Temperature Difference (LMTD) Method

The Logarithmic Mean Temperature Difference (LMTD) method is a widely used technique for analyzing heat exchanger performance, including double pipe heat exchangers. LMTD considers the temperature difference between the hot and cold fluids at various points along their paths. This method simplifies complex temperature profiles into a single value, making it easier to calculate heat transfer rates and assess efficiency.

C. Effectiveness-NTU (Number of Transfer Units) Method for Performance Evaluation

The Effectiveness-NTU method is another approach to evaluate the performance of double pipe heat exchangers and other types of heat exchangers. It uses the concept of the NTU, which represents the capacity of the exchanger to transfer heat. The effectiveness of the heat exchanger is calculated by comparing the actual heat transfer to the maximum possible heat transfer. This method provides insights into how well the exchanger performs relative to its ideal performance.

D. Factors Influencing the Performance of Double Pipe Heat Exchangers

Several factors impact the performance of double pipe heat exchangers, including fluid properties, flow rates, surface area, temperature differences, and the choice of materials. Properly understanding and controlling these factors are crucial for optimizing heat transfer efficiency and ensuring that the heat exchanger operates at its maximum potential.

In the subsequent sections of the article, we will explore the applications of double pipe heat exchangers in various industries, design considerations, maintenance challenges, recent advancements, and future trends. By comprehensively understanding the principles of performance evaluation, we can appreciate the impact of double pipe heat exchangers on enhancing energy efficiency and thermal management processes.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

VI. Applications of Double Pipe Heat Exchangers

A. Industrial Applications Across Various Sectors

Double pipe heat exchangers find versatile applications across a wide range of industries. They are utilized in chemical processing, petroleum refining, power generation, HVAC systems, food and beverage production, and more. The simplicity and compact design of these heat exchangers make them suitable for both large-scale industrial operations and smaller processes.

B. Case Studies Showcasing the Use of Double Pipe Heat Exchangers in Different Processes

Exploring specific case studies highlights how double pipe heat exchangers contribute to efficient heat transfer and energy management. Examples could include their use in recovering waste heat from exhaust gases in industrial processes, preheating fluids in power plants, or cooling applications in chemical reactors. These case studies demonstrate the practical impact of double pipe heat exchangers across diverse industries.

C. Advantages and Limitations in Specific Application Scenarios

While double pipe heat exchangers offer numerous advantages, such as their simple design and ease of maintenance, they also have limitations. These limitations could include lower heat transfer rates compared to more complex designs or potential challenges with fouling in certain applications. Understanding both the advantages and limitations helps engineers make informed decisions about when to utilize double pipe heat exchangers based on specific process requirements.

In the upcoming sections, we will explore the design considerations, maintenance challenges, recent innovations, and future trends related to double pipe heat exchangers. By gaining insights into their applications and real-world use cases, we can appreciate the significant role these heat exchangers play in optimizing thermal processes across industries.

VII. Design Considerations and Optimization

A. Importance of Proper Design for Efficient Heat Transfer

The efficiency of double pipe heat exchangers is heavily influenced by their design. A well-thought-out design ensures that the heat exchanger can effectively transfer heat between the hot and cold fluids while minimizing pressure drop and other inefficiencies. Proper design considerations result in improved energy utilization and reduced operational costs.

B. Factors Influencing the Design Process

The design of double pipe heat exchangers takes into account various factors, including fluid properties, flow rates, temperature differences, and the desired heat transfer rate. The choice of materials is also crucial, considering compatibility with the fluids being exchanged and resistance to corrosion and fouling. Additionally, considerations about maintenance accessibility and space constraints play a role in determining the final design.

C. Optimization Techniques for Enhancing Heat Exchanger Performance

Engineers continually strive to optimize the performance of double pipe heat exchangers by employing various techniques. This includes optimizing the surface area of the heat exchanger to maximize heat transfer, improving fluid flow patterns to minimize fouling, and utilizing advanced computational tools for simulation and analysis. Optimization aims to achieve the best possible heat transfer efficiency while minimizing energy consumption and operational costs.

D. Computational Tools and Software Used in Double Pipe Heat Exchanger Design

Advancements in computational fluid dynamics (CFD) and heat transfer simulation software have significantly enhanced the design process of double pipe heat exchangers. Engineers can create virtual models to simulate fluid flow, heat transfer, and temperature profiles, enabling them to predict the performance of different design configurations. These tools facilitate the evaluation of multiple scenarios before physical construction, reducing the need for trial and error.

In the following sections, we will explore the maintenance challenges associated with double pipe heat exchangers, recent developments and innovations in heat exchanger technology, as well as the future trends shaping the field. By understanding the design considerations and optimization strategies, we can appreciate the engineering behind efficient heat transfer processes.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

VIII. Maintenance and Operational Challenges

A. Common Issues Affecting Heat Exchanger Operation

The reliable operation of double pipe heat exchangers can be hindered by various challenges. These include fouling, corrosion, scaling, and mechanical issues. Fouling involves the accumulation of deposits on heat exchanger surfaces, reducing heat transfer efficiency. Corrosion occurs due to the interaction between the fluid and the heat exchanger material, leading to material degradation. Scaling results from the precipitation of minerals from the fluid, forming a layer that impedes heat transfer.

B. Strategies for Cleaning, Maintenance, and Extending Lifespan

To address operational challenges, maintenance strategies are employed to ensure the longevity and efficiency of double pipe heat exchangers. Regular cleaning, such as chemical treatments and mechanical cleaning methods, helps prevent fouling and scaling. Corrosion-resistant materials and protective coatings are used to mitigate the effects of corrosion. Additionally, adopting preventive maintenance schedules and monitoring systems aids in identifying and addressing issues before they escalate.

C. Impact of Maintenance on Overall System Efficiency

Efficient maintenance practices directly impact the overall efficiency of industrial systems. Properly maintained double pipe heat exchangers ensure consistent heat transfer performance, reducing energy consumption and associated costs. Efficient heat exchangers contribute to stable processes and improve the overall reliability of industrial operations, thereby enhancing productivity and minimizing downtime.

In the upcoming sections, we will explore recent developments and innovations in double pipe heat exchanger technology, as well as the future trends shaping the field. By understanding the challenges associated with maintenance and operational reliability, we can appreciate the importance of robust maintenance strategies in ensuring the continuous and effective operation of heat exchangers.

IX. Recent Developments and Innovations

A. Advances in Materials and Fabrication Techniques

The field of double pipe heat exchangers has witnessed significant advancements in materials and fabrication methods. Novel materials with improved thermal conductivity, corrosion resistance, and mechanical properties are being explored. Additionally, advancements in additive manufacturing techniques are allowing for more intricate and customized heat exchanger designs, optimizing performance for specific applications.

B. Enhanced Surface Treatments and Coatings for Improved Heat Transfer

Innovations in surface treatments and coatings are enhancing the heat transfer capabilities of double pipe heat exchangers. Nanocoatings, microstructured surfaces, and hydrophobic coatings are being applied to heat exchanger surfaces to minimize fouling and improve fluid flow characteristics. These advancements contribute to higher efficiency and reduced maintenance requirements.

C. Integration of Double Pipe Heat Exchangers with Renewable Energy Systems

The global push toward sustainability has led to the integration of double pipe heat exchangers with renewable energy systems. These heat exchangers are playing a crucial role in processes such as geothermal heat pumps, solar thermal systems, and biomass energy production. By effectively transferring and managing thermal energy, double pipe heat exchangers are helping to harness renewable energy sources more efficiently.

D. Role of Digitalization and IoT in Monitoring and Optimizing Performance

The rise of digitalization and the Internet of Things (IoT) has revolutionized the monitoring and optimization of double pipe heat exchangers. Sensors and data analytics tools are being employed to monitor heat exchanger performance in real-time, allowing for early detection of issues and predictive maintenance. These technologies enhance efficiency, reduce downtime, and contribute to overall operational excellence.

In the subsequent sections, we will explore future trends and the outlook for double pipe heat exchangers in various industries. By understanding recent innovations and technological advancements, we can grasp the evolving landscape of heat exchanger technology and its potential to shape more sustainable and efficient processes.

X. Future Trends and Outlook

A. Emerging Applications in Response to Evolving Industrial Needs

As industries evolve and new challenges arise, double pipe heat exchangers are likely to find innovative applications. With increased focus on sustainability, heat exchangers may play a key role in enhancing energy efficiency and reducing greenhouse gas emissions. Emerging fields such as waste heat recovery, advanced manufacturing processes, and sustainable energy systems could leverage the advantages of double pipe heat exchangers.

B. Potential Areas for Further Research and Development

The field of heat exchanger technology, including double pipe heat exchangers, offers ample room for further research and development. Exploration into new materials, advanced coatings, and innovative design configurations could lead to improved performance and efficiency. Additionally, investigating new methods for fouling mitigation, corrosion resistance, and enhancing heat transfer rates remains a priority.

C. Role of Sustainability and Energy Efficiency in Shaping the Future

The overarching trend of sustainability and energy efficiency will continue to shape the future of double pipe heat exchangers. Industries are under increasing pressure to reduce their environmental footprint and optimize energy usage. Heat exchangers, being integral components of various processes, will play a pivotal role in achieving these goals by enabling efficient thermal management and heat recovery.

In conclusion, double pipe heat exchangers are poised to be instrumental in driving advancements in heat transfer technology. By anticipating emerging applications, fostering research, and embracing sustainable practices, the field will contribute to more energy-efficient and environmentally conscious industrial processes.

In the final section of the article, we will recap the key points discussed throughout the article, emphasizing the importance of double pipe heat exchangers in various industries and encouraging further exploration and innovation in the realm of heat exchanger design and technology.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

XI. Conclusion

In this comprehensive exploration of double pipe heat exchangers, we’ve delved into their significance, design principles, heat transfer mechanisms, performance evaluation, applications, maintenance challenges, recent innovations, and future trends. These heat exchangers, known for their simplicity and efficiency, play a crucial role in various industries by facilitating optimal heat transfer and energy management.

Through understanding the fundamental heat transfer modes of conduction, convection, and radiation, as well as the impact of factors like fluid properties and flow arrangements, we’ve gained insights into the intricate processes that occur within double pipe heat exchangers. We’ve learned how their performance is evaluated using parameters like the overall heat transfer coefficient (U) and methods like the Logarithmic Mean Temperature Difference (LMTD) and the Effectiveness-NTU approach.

Furthermore, we’ve explored the practical applications of double pipe heat exchangers across diverse sectors, ranging from chemical processing to renewable energy systems. We’ve examined the importance of proper design and optimization techniques, considering factors like materials, fabrication methods, and computational tools. The challenges of maintenance, including fouling, corrosion, and scaling, have also been addressed, highlighting the significance of robust maintenance strategies.

Innovation remains a driving force in the field of double pipe heat exchangers, with advancements in materials, coatings, and integration with renewable energy systems. The role of digitalization and IoT has revolutionized monitoring and optimization practices, enhancing overall system efficiency.

Looking ahead, emerging applications, further research, and sustainability considerations are poised to shape the future of double pipe heat exchangers. With the global focus on energy efficiency and environmental responsibility, these heat exchangers will continue to play a pivotal role in achieving these goals across industries.

In conclusion, double pipe heat exchangers represent a cornerstone of heat transfer technology, offering efficiency, versatility, and potential for innovation. By recognizing their significance and embracing ongoing advancements, we can drive the evolution of heat exchanger design and contribute to more sustainable and efficient industrial processes.

FAQs

- What is a double pipe heat exchanger?A double pipe heat exchanger is a type of heat exchanger that consists of two concentric pipes or tubes, one within the other. Hot and cold fluids flow through these pipes, allowing for efficient heat transfer between the fluids without direct mixing. This design is known for its simplicity, ease of maintenance, and cost-effectiveness.

- What are the advantages of using double pipe heat exchangers?Double pipe heat exchangers offer several advantages, including:

- Simplicity in design and construction, leading to ease of maintenance.

- Versatility in handling a wide range of fluid types and temperature differences.

- Cost-effectiveness, making them suitable for various applications.

- Compact size, making them suitable for limited space installations.

- What are the common applications of double pipe heat exchangers?Double pipe heat exchangers are used in various industries, including chemical processing, HVAC systems, power generation, and food production. They are employed for tasks such as heating, cooling, condensation, and waste heat recovery. Their adaptability and efficiency make them suitable for both industrial processes and everyday applications.

- What is the significance of the logarithmic mean temperature difference (LMTD) method in double pipe heat exchangers?The LMTD method is used to analyze the performance of heat exchangers, including double pipe heat exchangers. It simplifies complex temperature profiles along the length of the exchanger into a single value, aiding in heat transfer calculations and efficiency assessments. The LMTD method is especially useful when dealing with counterflow and parallel flow arrangements.

- How do advancements in materials impact double pipe heat exchangers?Advances in materials impact double pipe heat exchangers by offering improved thermal conductivity, corrosion resistance, and mechanical properties. These advancements lead to enhanced heat transfer efficiency, extended lifespan, and the ability to handle more challenging fluids. Novel materials also enable the design of heat exchangers that can operate under higher temperatures and pressures, expanding their potential applications.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What is a Double Pipe Heat Exchanger primarily used for?

Explanation: A Double Pipe Heat Exchanger is primarily used for heat transfer between two fluids, often with one fluid being heated while the other is cooled.

Question 2:

What is the advantage of a Double Pipe Heat Exchanger?

Explanation: A Double Pipe Heat Exchanger offers advantages such as a high heat transfer rate, low cost, and ease of maintenance, making it suitable for various applications.

Question 3:

How are the fluids typically arranged in a Double Pipe Heat Exchanger?

Explanation: Double Pipe Heat Exchangers typically use a counterflow arrangement, where the hot and cold fluids flow in opposite directions for efficient heat transfer.

Question 4:

What is the purpose of the inner pipe in a Double Pipe Heat Exchanger?

Explanation: The purpose of the inner pipe in a Double Pipe Heat Exchanger is to increase the heat transfer area, allowing for more efficient heat exchange between the two fluids.

Question 5:

What type of applications are well-suited for Double Pipe Heat Exchangers?

Explanation: Double Pipe Heat Exchangers are well-suited for a range of applications, including high-temperature industrial processes that require efficient heat transfer between fluids.