Introduction to Plate Heat Exchanger

In the world of industrial processes and thermal management, plate heat exchangers have emerged as a revolutionary technology, enabling efficient heat transfer across a wide range of applications. These compact and versatile devices play a pivotal role in industries such as HVAC, chemical processing, power generation, and more. This article delves into the intricate workings of plate heat exchangers, their advantages, design considerations, applications, and future trends.

Table of Contents

Similar Articles on other Exchangers

| Heat Exchanger Type | Check Article Link |

|---|---|

| Helical Coil Heat Exchanger | Link |

| Tube-in-Tube Heat Exchanger | Link |

| Spiral Heat Exchanger | Link |

| U-Tube Heat Exchanger | Link |

| Shell and Tube Heat Exchanger | Link |

| Plate Heat Exchanger | Link |

| Double Pipe Heat Exchanger | Link |

| Finned Tube Heat Exchanger | Link |

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

Working Principles of Plate Heat Exchangers

Heat Transfer Mechanisms

Plate heat exchangers leverage two fundamental heat transfer mechanisms: conduction and convection. Conduction involves the transfer of heat through direct contact between solids, while convection deals with heat transfer between a solid surface and a fluid in motion. These mechanisms combine to facilitate efficient thermal exchange within the exchanger.

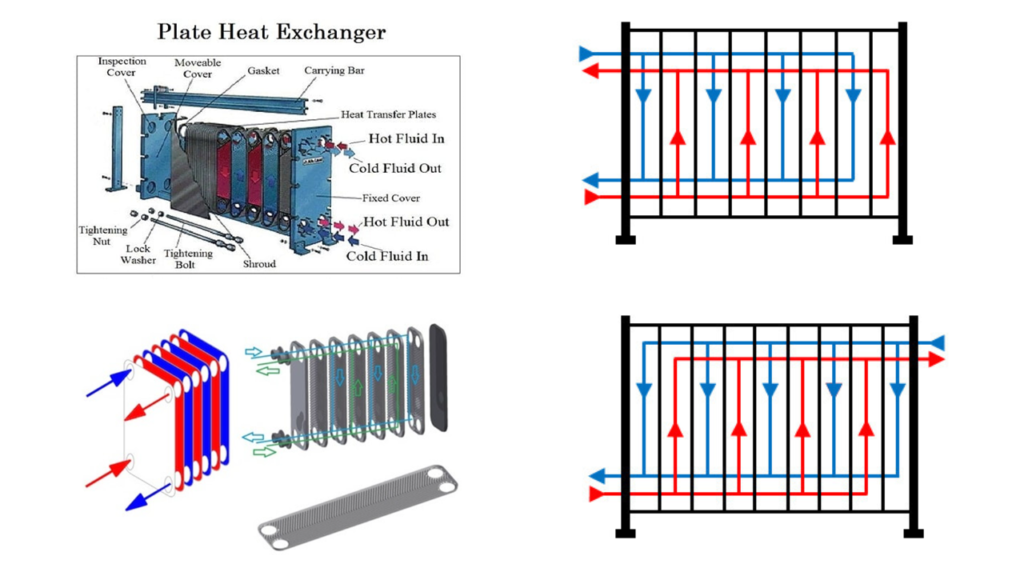

Fluid Flow Patterns

Three primary fluid flow patterns define the performance of plate heat exchangers: counterflow, parallel flow, and crossflow. Counterflow maximizes the temperature difference between the hot and cold fluids, leading to efficient heat transfer. Parallel flow maintains a constant temperature difference throughout the process, while crossflow is ideal for scenarios involving large temperature disparities.

Plate Design and Configurations

The heart of a plate heat exchanger lies in its design. Plates with intricate chevron patterns and corrugations create turbulence within the fluid channels. This turbulence enhances heat transfer by reducing the thermal boundary layer and promoting fluid mixing. Different corrugation types contribute to varying levels of heat transfer efficiency and pressure drop.

Advantages of Plate Heat Exchangers

Plate heat exchangers offer a multitude of advantages that have cemented their popularity in the industrial landscape:

High Efficiency

The turbulence-inducing design of plate heat exchangers significantly enhances heat transfer rates. The close proximity of the plates ensures minimal heat loss, translating to remarkable thermal efficiency.

Compactness and Space-Saving

Compared to traditional shell and tube heat exchangers, plate heat exchangers take up considerably less space. Their compact nature is particularly advantageous in industries where space constraints are a concern.

Flexibility in Design and Capacity

Plate heat exchangers can be customized to suit specific requirements, enabling versatile applications across various industries. They can be easily expanded or downsized to accommodate changing needs.

Reduced Fouling and Maintenance

The turbulent flow and smooth surfaces of plates discourage the buildup of deposits and fouling. This characteristic minimizes maintenance efforts and ensures consistent performance over time.

Improved Heat Recovery

The efficiency of plate heat exchangers makes them ideal for heat recovery applications. Waste heat from one process can be efficiently transferred to another, contributing to energy conservation.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

Codes & Standards for Plate Heat Exchanger

| Code/Standard | Description |

|---|---|

| ASME BPVC Section VIII, Div. 1 | Boiler and Pressure Vessel Code – Rules for Construction of Pressure Vessels |

| ASME MTC 47 | Method of Test for Rating Heat Exchangers |

| TEMA Standards | Tubular Exchanger Manufacturers Association Standards |

| API 662 | Plate Heat Exchangers for General Refinery Services |

| ISO 15547 | Plate Heat Exchangers – Part 1: Plate and Frame Heat Exchangers |

| EN 10204 | Metallic Products – Types of Inspection Documents |

| ANSI/HI 3.6 | Rotodynamic (Centrifugal) Pumps for Nomenclature, Definitions, Application, and Operation |

| ASTM A240 | Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications |

| API 662 | Plate Heat Exchangers for General Refinery Services |

| DIN EN 13445 | Unfired Pressure Vessels – Part 3: Design |

| JIS B 8223 | Water Conditioning for Boiler Feed Water and Boiler Water |

| PED 2014/68/EU | Pressure Equipment Directive for Europe |

| NFPA 85 | Boiler and Combustion Systems Hazards Code |

| AD 2000 Code | German Code for Pressure Vessel Design |

| NACE MR0175 | Sour Service (Sulfide Stress Cracking Resistant Metallic Materials) |

| API 662 | Plate Heat Exchangers for General Refinery Services |

Industrial Applications

Plate heat exchangers find utility in a diverse array of industries, each benefiting from their unique characteristics:

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, plate heat exchangers facilitate efficient heat exchange between incoming and outgoing air streams. Radiant heating and air conditioning systems both rely on these devices to maintain comfortable indoor environments.

Chemical and Petrochemical Industry

The chemical and petrochemical sectors utilize plate heat exchangers for process heating and cooling, as well as fluid condensation. Their compact design is particularly advantageous in complex chemical processes.

Food and Beverage Industry

Plate heat exchangers play a pivotal role in the food and beverage industry, enabling processes such as pasteurization and refrigeration. They ensure the safe production and preservation of consumable products.

Power Generation

Plate heat exchangers contribute to power generation by facilitating waste heat recovery and cooling in power plants. They aid in improving overall energy efficiency and reducing environmental impact.

Oil and Gas Industry

In the oil and gas industry, plate heat exchangers are vital for crude oil refining and heat recovery within pipelines. Their robustness and efficiency make them a reliable choice for demanding oil and gas operations.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

Design Considerations

Designing an effective plate heat exchanger requires careful consideration of various factors:

Plate Material Selection

The choice of plate material depends on the fluids being processed and their corrosiveness. Common materials include stainless steel, titanium, and nickel alloys, each offering distinct advantages in terms of durability and chemical resistance.

Fluid Compatibility and Corrosion Resistance

Compatibility between the heat exchanger’s plates and the fluids being transferred is crucial to prevent corrosion and ensure a long operational lifespan. Corrosion-resistant coatings and gasket materials play a pivotal role in maintaining the exchanger’s integrity.

Heat Exchanger Sizing and Thermal Performance

Proper sizing ensures optimal heat transfer efficiency. Factors such as flow rates, temperature differences, and fluid properties are meticulously calculated to determine the ideal dimensions of the plate heat exchanger.

Pressure Drop Considerations

Balancing heat transfer efficiency with acceptable pressure drops is essential. Excessive pressure drops can lead to energy losses and hinder the overall performance of the system.

Gasket Selection and Maintenance

Gaskets are critical components that seal the gaps between plates, preventing fluid leakage. Regular inspection and replacement of gaskets are necessary to maintain the heat exchanger’s integrity and efficiency.

Installation and Maintenance

Pre-Installation Checks and Preparations

Before installation, a thorough inspection of plates, gaskets, and other components is conducted to ensure they are free from defects. Proper alignment and connection of inlet and outlet pipes are essential for optimal performance.

Installation Procedures

The installation process involves carefully assembling the plates, securing them in the frame, and aligning them to ensure proper flow paths. Tightening bolts to recommended torque values ensures uniform clamping pressure across the plates.

Regular Maintenance Practices

Routine maintenance includes inspecting and cleaning plates, replacing worn-out gaskets, and checking for any signs of leakage. Cleaning methods range from chemical treatments to mechanical methods depending on the type of fouling.

Troubleshooting Common Issues

Plate heat exchangers may encounter issues such as reduced heat transfer efficiency, pressure drops, or leaks. Identifying the root causes of these problems and implementing appropriate solutions is crucial to maintaining smooth operations.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

Performance Optimization

To enhance the performance of plate heat exchangers, several strategies can be employed:

Thermal Efficiency Enhancement

Improving flow distribution among plates and using surface enhancement techniques like dimpled plates or surface coatings can significantly enhance heat transfer efficiency.

Fouling Mitigation Strategies

To combat fouling, chemical treatments can be employed to prevent deposit buildup on plate surfaces. In cases of severe fouling, physical cleaning methods such as high-pressure water jets or mechanical scraping can restore performance.

Challenges and Limitations

While plate heat exchangers offer numerous advantages, they also come with certain challenges and limitations:

High Initial Costs

The upfront investment in plate heat exchangers can be higher compared to traditional heat exchangers. However, their long-term energy savings and operational benefits often outweigh this initial cost.

Complex Design for Some Applications

In applications with highly viscous or particulate-laden fluids, plate heat exchangers might require complex designs or additional pre-filtration to prevent clogging and fouling.

Susceptibility to High-Pressure Differentials

Plate heat exchangers are sensitive to high-pressure differentials between the hot and cold sides. Careful design and operation are necessary to avoid structural damage or leakage.

Potential for Fouling in Certain Fluids

While plate heat exchangers are less prone to fouling compared to other types, certain fluids with high fouling tendencies might still pose challenges over extended operations.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

Comparative Analysis with Other Heat Exchanger Types

Shell and Tube Heat Exchangers

Compared to shell and tube heat exchangers, plate heat exchangers offer higher heat transfer efficiency due to their increased surface area. However, shell and tube exchangers are more suitable for high-pressure and high-temperature applications.

Finned Tube Heat Exchangers

Finned tube heat exchangers are efficient for air-to-fluid heat exchange, while plate heat exchangers excel in fluid-to-fluid applications. Finned tubes are bulkier, making them less space-efficient than their plate counterparts.

Air Cooled Heat Exchangers

Air cooled heat exchangers are ideal when water availability is limited or costly. However, they often have lower heat transfer rates compared to plate heat exchangers and can be affected by ambient temperature variations.

Future Trends in Plate Heat Exchangers

Advances in Materials and Coatings

Ongoing research aims to develop new materials and coatings that enhance corrosion resistance and heat transfer efficiency, allowing plate heat exchangers to withstand more aggressive operating conditions.

Integration with Renewable Energy Systems

Plate heat exchangers are being integrated into renewable energy systems such as solar thermal collectors and geothermal heat pumps, amplifying their role in sustainable energy production.

Smart Heat Exchanger Technologies

The integration of sensors, IoT capabilities, and data analytics is transforming plate heat exchangers into smart devices. Real-time monitoring and performance optimization contribute to efficient operation.

Environmental Considerations

Environmental concerns are driving the development of eco-friendly heat transfer fluids that align with sustainability goals. Plate heat exchangers are poised to adapt to these greener alternatives.

Case Studies

Energy-Efficient District Heating System

Plate heat exchangers play a pivotal role in district heating systems, where waste heat from industrial processes is captured and redistributed for residential and commercial use, significantly reducing energy consumption.

Process Intensification in the Chemical Industry

The chemical industry benefits from the compactness and efficiency of plate heat exchangers to enhance process intensification, reducing production costs and environmental impact.

Plate Heat Exchangers in Sustainable Refrigeration

In the refrigeration industry, plate heat exchangers are crucial for improving energy efficiency and reducing the environmental footprint of cooling systems, particularly in commercial and industrial refrigeration.

Don’t miss the Detailed course on Drums/Exchanger Piping Layout & Stress Analysis

Enrollment Link

Conclusion

Plate heat exchangers have revolutionized the field of heat transfer, offering unparalleled efficiency, compactness, and versatility across a myriad of industrial applications. Their significance in industries spanning from HVAC to power generation cannot be overstated. As technology continues to evolve, these devices are poised to lead the charge in efficient thermal management, contributing to a more sustainable and energy-efficient future.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What is a Plate Heat Exchanger?

Explanation: A Plate Heat Exchanger is a device designed to efficiently transfer heat between two fluids by utilizing a series of metal plates to create a large surface area for heat exchange.

Question 2:

What is the primary advantage of using Plate Heat Exchangers?

Explanation: The primary advantage of Plate Heat Exchangers is their compact design, which allows for efficient heat transfer in a relatively small space compared to traditional shell-and-tube heat exchangers.

Question 3:

Which type of fluid flow arrangement is commonly used in Plate Heat Exchangers?

Explanation: The most common fluid flow arrangement in Plate Heat Exchangers is the counterflow arrangement, where the hot and cold fluids flow in opposite directions to maximize heat transfer efficiency.

Question 4:

What materials are often used for the plates in Plate Heat Exchangers?

Explanation: Plates in Plate Heat Exchangers are typically made from metal, such as stainless steel or titanium, due to their excellent thermal conductivity and corrosion resistance.

Question 5:

What applications are Plate Heat Exchangers commonly used for?

Explanation: Plate Heat Exchangers are commonly used in various applications, including both domestic water heating and air conditioning systems, as well as industrial processes, chemical industries, and more.