1. What is the primary function of Centrifugal Pump Bearings?

Choose the correct statement regarding the role of bearings.

Explanation: Bearings in a centrifugal pump provide support to the rotating shaft and absorb radial and axial forces, ensuring smooth and stable rotation.

2. What role do Centrifugal Pump Bearings play in alignment control?

Select the statement that accurately describes the contribution of bearings to pump alignment.

Explanation: Bearings help maintain proper alignment of the shaft, minimizing friction and wear while maximizing pump efficiency.

3. Which type of Centrifugal Pump Bearings are suitable for large pumps and high axial thrust loads?

Identify the specialized bearing designed to handle high axial thrust loads.

Explanation: Pivoted-Shoe Thrust Bearings are specialized bearings designed to handle high axial thrust loads, commonly found in large pumps.

4. What factor influences the choice of the optimal bearing type?

Consider various factors influencing the selection of the optimal bearing type for a centrifugal pump.

Explanation: The optimal bearing type is influenced by factors such as operating temperature, pump size and speed, lubrication requirements, and cost.

5. What is a key consideration for selecting bearings in larger pumps operating at higher speeds?

Identify the crucial consideration for bearing selection in larger and higher-speed pumps.

Explanation: Larger pumps and those operating at higher speeds require robust bearings with higher load-carrying capacity.

6. What role does proactive maintenance play in bearing performance?

Understand the importance of proactive maintenance for optimal bearing performance.

Explanation: Proactive maintenance, including regular lubrication, monitoring vibration levels, and visual inspection, maximizes bearing lifespan and ensures efficient pump operation.

7. What can excessive vibrations in a pump indicate regarding bearings?

Understand the significance of excessive vibrations and their relation to bearing problems.

Explanation: Excessive vibrations in a pump can indicate bearing problems, and prompt attention is required to address potential issues.

Don’t Miss the Relevant Topics on Centrifugal Pumps

| Topics on Centrifugal Pumps | Topics on Centrifugal Pumps |

| Working Principle of Centrifugal Pumps | Centrifugal Pump Mechanical Seals |

| Centrifugal Pump Bearings | Centrifugal Pump Shaft |

| Types of Centrifugal Pumps | Centrifugal Pump Impellers |

| Centrifugal Pump Casing |

Short Article on Centrifugal Pump Bearings

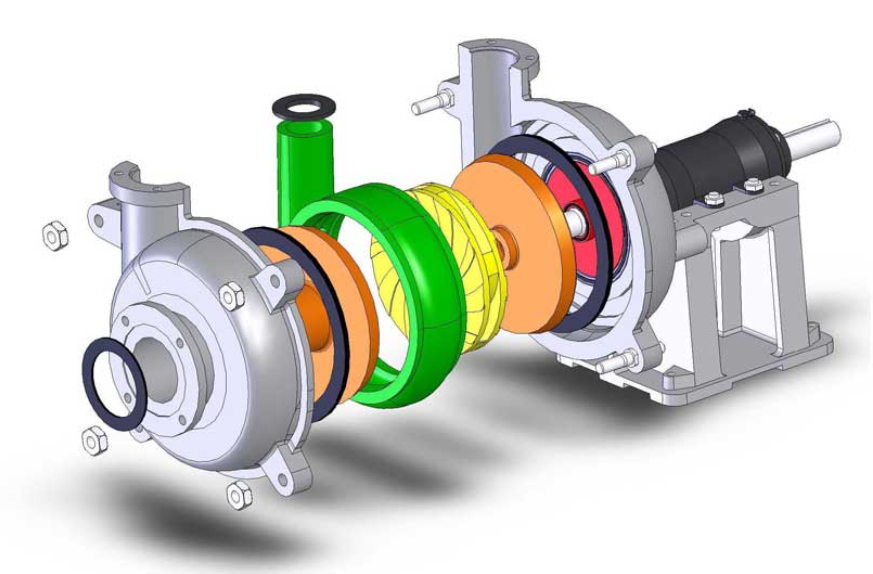

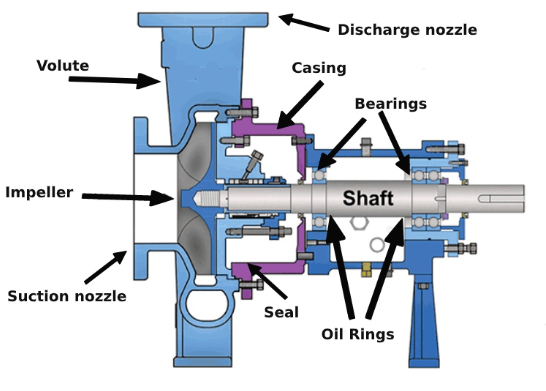

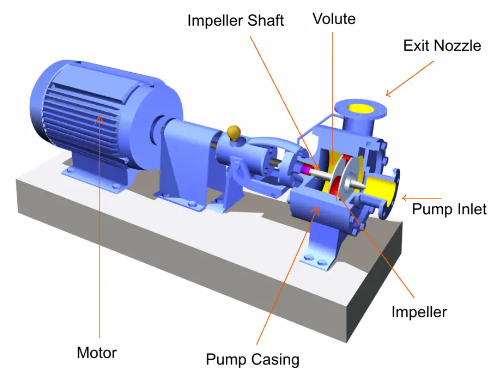

Centrifugal pumps are the workhorses of countless industries, but their smooth operation hinges on a crucial yet often unseen component – the bearings. These silent guardians play a vital role in ensuring efficiency, reliability, and long-lasting pump performance.

Bearing Function and Importance:

- Shaft Support: Bearings provide support to the rotating shaft and other components within the pump housing. They absorb the radial and axial forces generated during operation, ensuring smooth and stable rotation.

- Alignment Control: Bearings help maintain proper alignment of the shaft, minimizing friction and wear while maximizing pump efficiency.

- Vibration Reduction: Efficient bearings effectively absorb vibrations, reducing noise and stress on other pump components.

Types of Centrifugal Pump Bearings:

The specific type of bearing used in a centrifugal pump depends on the operating conditions and the pump design. Some common examples include:

- Anti-friction Bearings: These include ball bearings and roller bearings, known for their low friction and long lifespan. They are widely used in high-speed pumps with moderate loads.

- Pivoted-Shoe Thrust Bearings: These specialized bearings are designed to handle high axial thrust loads, commonly found in large pumps and those operating at high pressures.

- Sleeve Bearings: These are simpler in design but require precise alignment and lubrication. They are often used in low-speed pumps or when cost is a primary concern.

Choosing the Right Bearings:

Selecting the optimal bearing type necessitates considering several factors:

- Pump size and speed: Larger pumps and those operating at higher speeds require robust bearings with higher load-carrying capacity.

- Operating temperature: Bearings must be compatible with the operating temperature of the pump and the pumped fluid.

- Lubrication requirements: Different bearing types require specific lubrication methods and frequencies.

- Cost and maintenance: Anti-friction bearings offer lower maintenance needs but can be more expensive than sleeve bearings.

Ensuring Optimal Bearing Performance:

Proactive maintenance plays a crucial role in maximizing bearing lifespan and ensuring efficient pump operation. This includes:

- Regular lubrication: Maintaining the correct lubrication level and using the recommended lubricants is essential for reducing friction and wear.

- Monitoring vibration levels: Excessive vibrations can indicate bearing problems and require prompt attention.

- Inspecting bearings regularly: Regular visual inspection and testing can help identify potential issues before they lead to failure.

Conclusion:

Though often overlooked, centrifugal pump bearings play a vital role in ensuring efficient, reliable, and long-lasting operation. Understanding their function, types, and selection criteria empowers us to make informed choices and implement proper maintenance practices. By doing so, we can ensure the silent guardians continue to safeguard the smooth and efficient flow of countless industrial processes.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.