1. What is the primary function of centrifugal pump mechanical seals?

Choose the correct statement regarding the function of mechanical seals.

Explanation: Mechanical seals primarily prevent leaks along the rotating shaft and contribute to efficient pump operation.

2. What is the role of mechanical seals in efficiency enhancement?

Select the statement that correctly describes how mechanical seals contribute to pump efficiency.

Explanation: Mechanical seals contribute to pump efficiency by minimizing leaks, leading to reduced energy consumption.

3. What type of mechanical seal features two sets of mating faces with a buffer fluid in between?

Identify the correct type of mechanical seal described in the context.

Explanation: Double Mechanical Seals feature two sets of mating faces with a buffer fluid in between for increased reliability.

4. What is a key consideration when choosing the right mechanical seal for a centrifugal pump?

Select the factor that must be considered in the selection of mechanical seals.

Explanation: The nature of the process fluid is a crucial factor in selecting the right mechanical seal.

5. What is the purpose of regular inspection in maintaining mechanical seal performance?

Choose the correct reason for conducting regular inspections of mechanical seals.

Explanation: Regular inspection is crucial for early detection of wear and tear issues in mechanical seals.

6. Why is the replacement of worn or damaged seals important for pump maintenance?

Select the correct statement regarding the importance of seal replacement.

Explanation: Prompt replacement of worn or damaged seals minimizes the risk of leaks and costly downtime.

7. Why is proper lubrication important for some mechanical seals?

Select the correct reason for ensuring proper lubrication in specific mechanical seals.

Explanation: Proper lubrication is essential to maintain optimal performance and prevent premature wear in specific mechanical seals.

Don’t Miss the Relevant Topics on Centrifugal Pumps

| Topics on Centrifugal Pumps | Topics on Centrifugal Pumps |

| Working Principle of Centrifugal Pumps | Centrifugal Pump Mechanical Seals |

| Centrifugal Pump Bearings | Centrifugal Pump Shaft |

| Types of Centrifugal Pumps | Centrifugal Pump Impellers |

| Centrifugal Pump Casing |

Short Article on Centrifugal Pump Mechanical Seals

Centrifugal Pump Mechanical Seals: Guardians Against Leakage and Ensurers of Efficiency

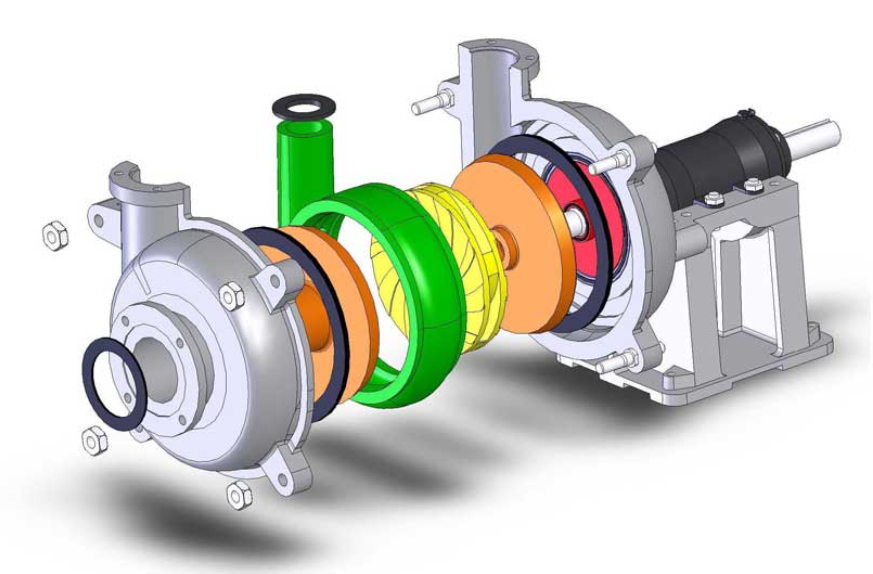

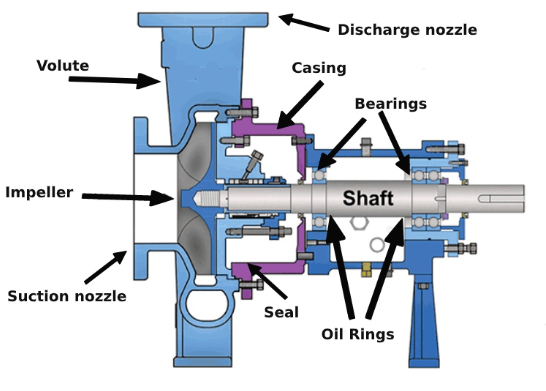

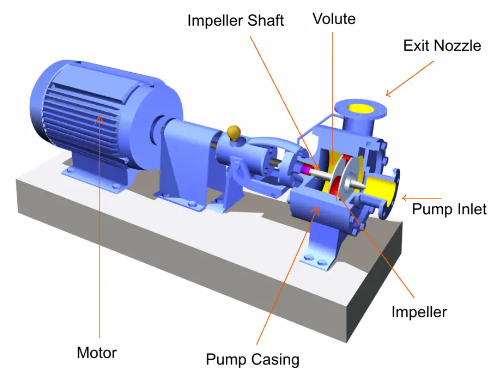

The heart of a centrifugal pump may lie in its impeller, but the responsibility for preventing leaks and ensuring efficient operation falls upon the mechanical seals. These unsung heroes, often housed within the casing cover, form a critical barrier between the pumped fluid and the surrounding environment.

Function and Importance:

- Leakage Prevention: Mechanical seals effectively prevent leaks along the rotating shaft, safeguarding the environment and protecting valuable process fluids.

- Efficiency Enhancement: By minimizing leaks, mechanical seals contribute to improved pump performance and reduced energy consumption.

- Extended Lifespan: Efficient seals minimize wear and tear on the pump shaft and other components, extending the pump’s lifespan.

Types of Mechanical Seals:

The specific type of mechanical seal employed in a centrifugal pump depends on the operating conditions and the pumped fluid. Some common types include:

- Single Mechanical Seals: These are the simplest and most common design, featuring two mating faces that rotate against each other with a thin film of fluid separating them.

- Double Mechanical Seals: These offer increased reliability and protection for high-pressure or hazardous fluids, featuring two sets of mating faces with a buffer fluid in between.

- Cartridge Seals: These pre-assembled units are easy to install and maintain, making them popular for high-maintenance environments.

Selection Criteria:

Choosing the right mechanical seal necessitates careful consideration of several factors:

- Nature of Process Fluid: The seal materials and design must be compatible with the chemical properties and abrasiveness of the pumped fluid.

- Operating Temperature and Pressure: The seal must be able to withstand the specific temperature and pressure conditions of the pump’s operation.

- Shaft Speed: Higher shaft speeds require seals designed for high-speed performance and reduced friction.

- Environmental Considerations: The seal must comply with any environmental regulations or safety requirements applicable to the process.

Maintaining Seal Performance:

Proper maintenance practices are essential for ensuring the longevity and effectiveness of mechanical seals:

- Regular inspection: Visual inspection for wear and tear is crucial for early detection of potential problems.

- Seal replacement: Replacing worn or damaged seals promptly minimizes the risk of leaks and costly downtime.

- Proper lubrication: Some seals require specific lubrication to maintain optimal performance and prevent premature wear.

Conclusion:

Centrifugal pump mechanical seals play a vital role in preventing leaks, enhancing efficiency, and extending the lifespan of the pump. By understanding their function, types, selection criteria, and maintenance requirements, we can ensure these silent guardians continue to safeguard the smooth and efficient operation of countless industrial processes.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.