1. What is a critical factor in determining the required support span for pipe supports?

Choose the correct factor influencing pipe support spans:

Explanation: The weight of the pipe, fluid, and insulation (fluid type) is a critical factor in determining the required support span for pipe supports.

2. What is the maximum deflection limit typically recommended for pipes up to DN 42 (NPS 24″)?

Choose the correct maximum deflection limit for pipes up to DN 42:

Explanation: The maximum deflection limit for pipes up to DN 42 (NPS 24″) is typically 16 mm (5/8″).

3. What might influence the pipe rack bend spacing and, consequently, the support span?

Choose the correct factor that might influence the pipe rack bend spacing:

Explanation: Space constraints around equipment may influence the pipe rack bend spacing and, consequently, the support span.

4. What is the role of guides in a piping system?

Choose the correct role of guides in a piping system:

Explanation: Guides help maintain proper pipe alignment and prevent lateral movement in a piping system.

5. What is a crucial factor for guide spacing in a piping system?

Choose the correct factor influencing guide spacing:

Explanation: The recommended spacing for guides depends on the pipe size and material in a piping system.

6. What is the maximum spacing for pipe supports in process units, common pipe racks, and major facilities?

Choose the correct maximum spacing for pipe supports in certain areas:

Explanation: In process units, common pipe racks, and major facilities, the maximum spacing for pipe supports is typically 6 meters.

7. Why might smaller pipe sizes (DN 42 and below) require closer support spacing?

Choose the correct reason for closer support spacing in smaller pipe sizes:

Explanation: Smaller pipe sizes (DN 42 and below) might require closer support spacing even if the deflection limit is met, to prevent excessive vibration or noise.

Don’t Miss 20+ Quizzes on Pipe Supports:

Short Article on Pipe Support Spans

Pipe Support Spans and Guide Spacing: A Guide to Optimal Piping Design

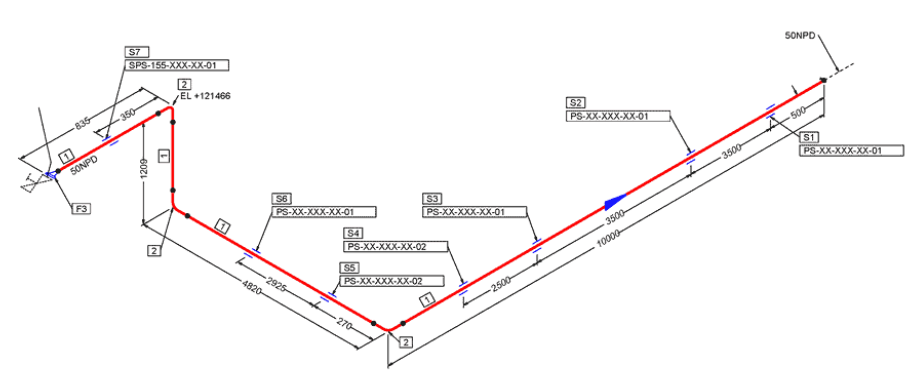

Pipe supports and guides are critical components of any piping system, ensuring the stability, alignment, and integrity of the pipeline. Choosing the right spacing for these elements is crucial for optimal performance and avoiding potential problems like sagging, misalignment, and stress buildup.

Factors Influencing Pipe Support Spans:

- Load: The weight of the pipe, fluid, and insulation plays a crucial role in determining the required support span.

- Pipe size: Smaller pipes generally require more frequent support to prevent excessive deflection.

- Fluid type: Liquid-filled lines typically need closer support spacing compared to gas-filled lines due to their higher weight.

- Temperature: Hot lines require shorter support spans than cold lines of the same size and thickness due to thermal expansion.

- Insulation: Insulated lines need closer support spacing due to the additional weight of the insulation.

- Equipment spacing: Space constraints around equipment may influence the pipe rack bend spacing and, consequently, the support span.

Design Considerations:

- Maximum deflection: The chosen support spacing should ensure that the maximum deflection of the pipe remains within acceptable limits, typically 16 mm (5/8″) for pipes up to DN 42 (NPS 24″).

- Material properties: Different materials have varying strength and deflection characteristics, requiring adjustments to the support span.

- Company standards: Specific project requirements and company standards may dictate different spacing recommendations.

Recommended Spans:

The table you provided offers a general guideline for maximum recommended pipe support spans for different materials and sizes. However, it’s important to note that these values are just a starting point and may need to be adjusted based on the specific factors mentioned above.

Guide Spacing:

Guides help maintain proper pipe alignment and prevent lateral movement. The recommended spacing for guides also depends on the pipe size and material. The provided table offers a general framework for guide spacing, but specific project conditions may necessitate adjustments.

Additional Points:

- In process units, common pipe racks, and major facilities, the maximum spacing for pipe supports is typically 6 meters.

- Smaller pipe sizes (DN 42 and below) might require closer support spacing even if the deflection limit is met, to prevent excessive vibration or noise.

- Consulting engineering standards and project specifications is crucial for determining the most accurate pipe support and guide spacing for a specific application.

Conclusion:

By understanding the factors influencing pipe support spans and guide spacing, and by referring to recommended guidelines and relevant standards, you can ensure optimal design and installation of your piping systems. This will ultimately contribute to the safe, efficient, and long-term operation of your piping infrastructure.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.