Introduction

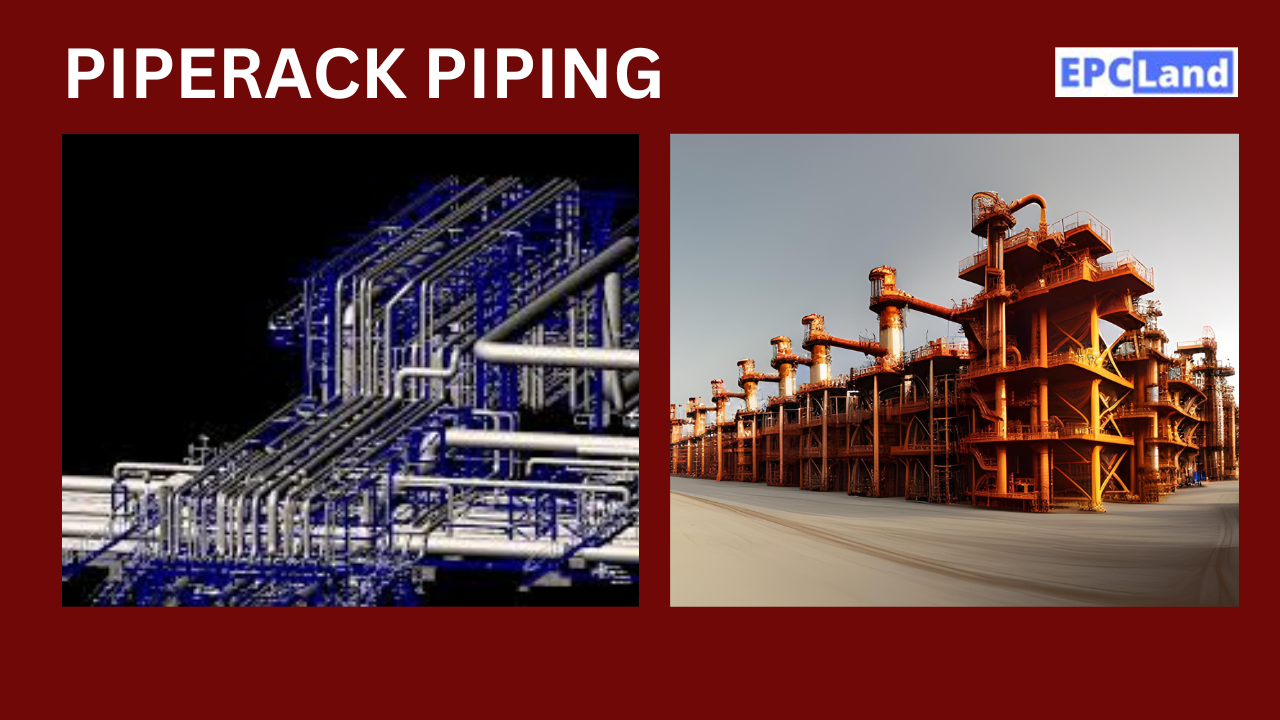

In the complex landscape of the oil and gas industry, piperack piping emerges as a crucial and often overlooked component. With its intricate web of pipes, supports, and utilities, piperack systems play an indispensable role in the safe and efficient operation of oil and gas facilities. These systems not only ensure the seamless flow of various fluids but also serve as the backbone for the distribution of utilities such as instrument lines, electrical cables, and communication networks.

Table of Contents

Do not miss the detailed course on Piperack Piping

Enrollment Link

Significance of Piperack Piping

Piperacks are essentially structural frameworks designed to support, route, and organize the extensive network of pipes that interconnect throughout a processing facility. They provide the necessary structural integrity to withstand the dynamic forces, including vibration and seismic activity, often encountered in industrial environments.

The strategic placement of piperacks within the facility serves multiple purposes. It ensures the separation of different process lines, reducing the risk of cross-contamination and enhancing safety. Piperack designs also take into account considerations such as accessibility for maintenance, expansion capabilities, and overall plant layout.

Piperack piping systems essentially form the circulatory system of an oil and gas facility, facilitating the movement of crucial fluids and resources that are vital for production, refining, and distribution. Understanding the fundamental role of piperacks in the industry lays the foundation for delving into their intricate design, functionality, challenges, and best practices.

1. Piperack Piping Design

The backbone of an efficient and safe piperack piping system lies in its meticulous design. This initial phase involves a comprehensive assessment of various factors that influence the layout and configuration of the piperacks. A well-thought-out design not only ensures the optimal flow of fluids and utilities but also addresses critical safety and maintenance considerations.

Factors Influencing Piperack Layout

- Safety: Safety is paramount in the oil and gas industry. Piperack designs must adhere to strict safety standards to prevent accidents, leaks, and other hazards. Separation of process lines to avoid cross-contamination and maintaining adequate clearance for maintenance are crucial safety considerations.

- Accessibility and Maintenance: Ease of access for maintenance personnel is essential to ensure timely inspections, repairs, and replacements. Properly designed piperacks allow for safe and convenient access to various pipes and utilities, reducing downtime and enhancing operational efficiency.

- Expansion and Flexibility: The oil and gas industry is subject to changes in production demands and technological advancements. Piperack designs should account for potential expansions and modifications, enabling the facility to adapt to evolving requirements without significant disruptions.

- Plant Layout Integration: Piperacks are integral components of the overall plant layout. Their design should harmonize with other structural elements, equipment placement, and workflow patterns. A well-integrated piperack system contributes to a streamlined and organized facility layout.

Consideration of Process Pipes and Utilities

Different types of process pipes, ranging from high-pressure hydrocarbon lines to low-pressure utility lines, traverse piperacks. Additionally, piperacks house a variety of utilities, such as instrument lines for sensors, electrical cables for equipment power, and communication lines for data transmission. The design must account for the specific requirements of each pipe and utility type, ensuring proper support, insulation, and protection.

Conclusion

Piperack piping design is the cornerstone of an efficient and safe oil and gas facility. By carefully considering safety, accessibility, expansion, and integration with the plant layout, engineers can create piperack systems that facilitate the optimal flow of fluids and utilities while minimizing risks and downtime. In the subsequent sections, we delve deeper into the essential components of piperack systems, their functionality, challenges, and best practices.

Do not miss the detailed course on Piperack Piping

Enrollment Link

2. Key Components of Piperack Piping

Piperack piping systems consist of several integral components that collectively contribute to their structural integrity, functionality, and operational efficiency. These components work in synergy to support, route, and protect the intricate network of pipes and utilities that run throughout the oil and gas facility.

Main Structural Components

- Supports: Piperacks rely on sturdy supports, which are often steel structures like frames, trusses, or beams. These supports provide the necessary foundation for carrying the weight of the pipes, utilities, and any attached equipment. The choice of support structure depends on factors such as load-bearing capacity, span, and environmental conditions.

- Brackets and Clamps: Brackets and clamps are used to secure the pipes and utilities to the supports. These components prevent excessive movement, vibration, and stress on the pipes, ensuring their stability and longevity.

- Beams and Trusses: Beams and trusses are integral to the overall structural stability of the piperack. They distribute loads and forces evenly across the supports, minimizing the risk of localized stress concentrations.

Pipe Supports

- Clamps: Clamps securely hold pipes in place while allowing for thermal expansion and contraction. They come in various designs to accommodate different pipe diameters and configurations.

- Hangers: Hangers suspend pipes from the piperack supports. They are adjustable to account for variations in pipe movement due to temperature changes and operational conditions.

- Guides: Guides prevent lateral movement of pipes, ensuring they remain aligned within the piperack system. This is crucial for preventing clashes between pipes and maintaining efficient fluid flow.

Utilities

- Instrument Lines: These lines carry data from sensors and instruments, providing crucial information for monitoring and controlling the facility’s processes. Proper support and protection are essential to maintain accurate readings.

- Electrical Cables: Electrical cables power equipment and instruments throughout the facility. They require careful routing and protection to prevent damage, ensure safety, and maintain uninterrupted operations.

- Communication Lines: Communication lines transmit data and information across different parts of the facility. Shielding and proper separation from other lines are necessary to prevent interference and ensure reliable communication.

Conclusion

The effectiveness of piperack piping systems in the oil and gas industry hinges on the proper design and integration of these key components. Together, they create a robust framework that supports the extensive network of pipes and utilities, contributing to the safe and efficient operation of the facility. In the subsequent sections, we explore the functionality of piperack piping systems and the challenges associated with their design and operation.

3. Functionality of Piperack Piping

Piperack piping systems are at the heart of the oil and gas facility’s functionality, acting as the circulatory system that enables the smooth flow of fluids, utilities, and information. These systems play a pivotal role in maintaining safety, efficiency, and operational continuity throughout the facility.

Fluid Flow Facilitation

The primary function of piperack piping is to facilitate the movement of various fluids, including hydrocarbons, water, and chemicals, across different parts of the facility. The well-designed layout of piperacks ensures that fluids are transported from their source to their destination with minimal resistance, pressure drops, and the risk of leaks.

Safety Enhancement

Piperack piping contributes significantly to safety by maintaining separation between different types of fluids and utilities. This separation prevents cross-contamination and minimizes the potential for hazardous reactions. Additionally, proper support and routing prevent pipes from sagging or vibrating excessively, reducing the likelihood of damage and leaks.

Equipment and Instrument Support

Piperack systems serve as platforms for supporting equipment and instruments attached to the pipes. These include pumps, valves, sensors, and control instruments. By securely holding these components in place, piperacks ensure accurate readings, efficient control, and timely maintenance.

Plant Layout Integration

Piperack systems are strategically integrated into the overall plant layout, optimizing the use of available space while considering factors such as access for maintenance and expansion capabilities. Proper integration contributes to an organized and well-structured facility, facilitating the movement of personnel and equipment.

Conclusion

Piperack piping systems are the lifelines of oil and gas facilities, enabling the efficient transport of fluids, utilities, and information. By facilitating fluid flow, enhancing safety, supporting equipment, and integrating seamlessly with the plant layout, piperacks play an indispensable role in maintaining the facility’s functionality and productivity. In the following sections, we delve into the challenges and considerations associated with piperack piping design and the best practices for ensuring their optimal operation.

Do not miss the detailed course on Piperack Piping

Enrollment Link

4. Challenges and Considerations

Designing and operating piperack piping systems in the oil and gas industry come with a set of challenges and considerations that engineers and operators must address to ensure the safety, efficiency, and longevity of the facility.

Harsh Environmental Conditions

Oil and gas facilities often operate in harsh environments characterized by high temperatures, corrosive chemicals, and extreme weather conditions. Piperack materials must be selected to withstand these factors and prevent premature degradation.

Corrosion Prevention

Corrosion is a major concern due to the corrosive nature of many fluids transported through the pipes. Proper material selection, coatings, and cathodic protection systems are crucial to mitigate corrosion and extend the lifespan of the piperack system.

Dynamic Loads and Vibration

Vibration caused by equipment operation, seismic activity, and fluid flow can lead to fatigue and stress on pipes and supports. Dynamic load analysis and proper support design are essential to prevent failure and maintain structural integrity.

Clearance for Maintenance

Piperacks must provide sufficient clearance for maintenance personnel to access and work on the pipes, supports, and attached equipment. Inadequate clearance can lead to delays in maintenance, repairs, and inspections.

Thermal Movements

Temperature fluctuations cause pipes to expand and contract, which can lead to stress and misalignment. Expansion joints or flexible supports must be incorporated to accommodate thermal movements without compromising the integrity of the piperack system.

Conclusion

The challenges posed by harsh environments, corrosion, dynamic loads, clearance requirements, and thermal movements highlight the complexity of designing and maintaining piperack piping systems. Addressing these challenges requires a combination of engineering expertise, material selection, and adherence to industry standards. In the subsequent sections, we delve into best practices that can help overcome these challenges and ensure the optimal performance of piperack piping systems in the oil and gas industry.

5. Best Practices

Designing and operating piperack piping systems in the oil and gas industry demands a strategic approach and adherence to best practices that ensure safety, efficiency, and reliability. These practices encompass collaboration, compliance, analysis, and ongoing maintenance.

Collaboration between Engineers

Successful piperack design requires collaboration between piping and structural engineers. Piping engineers understand the flow requirements and materials, while structural engineers ensure the supports and framework can handle the loads.

Compliance with Industry Standards

Adherence to industry standards and codes, such as those set by ASME and API, is essential. These standards provide guidelines for material selection, design considerations, and safety measures.

Stress Analysis and Simulation

Conducting stress analysis and simulations helps identify potential weak points and stress concentrations in the piperack system. This analysis guides the selection of appropriate materials, support structures, and design modifications.

Regular Inspection and Maintenance

Routine inspection and maintenance are critical to identifying and addressing issues before they escalate. Regular checks ensure that the piperack system remains in optimal condition and can withstand operational demands.

Documentation of Procedures

Comprehensive documentation of design, installation, and maintenance procedures is essential for future reference. This documentation streamlines decision-making, troubleshooting, and compliance with regulatory requirements.

Conclusion

Implementing these best practices ensures that piperack piping systems are not only well-designed but also continue to function reliably over time. Collaboration, compliance, analysis, and ongoing maintenance form a comprehensive approach to addressing challenges and optimizing the performance of piperack systems in the oil and gas industry. In the subsequent sections, we explore real-world case studies that showcase successful implementations of piperack piping designs.

Do not miss the detailed course on Piperack Piping

Enrollment Link

6. Case Studies

Real-world case studies provide valuable insights into the successful implementation of piperack piping designs in prominent oil and gas projects. These examples highlight innovative solutions to specific challenges and demonstrate how effective piperack systems contribute to operational excellence.

Case Study 1: Offshore Production Platform

In this case, an offshore production platform required a piperack system to support a complex network of hydrocarbon pipes, utility lines, and communication cables. Challenges included harsh marine conditions, limited space, and strict safety regulations. Engineers collaborated to design a modular piperack system that could be assembled onshore and then transported to the platform for installation. The system incorporated corrosion-resistant materials, flexible supports to accommodate platform movements, and a robust clearance design for maintenance. The success of this project showcased the importance of interdisciplinary collaboration, innovative design, and careful consideration of operational challenges.

Case Study 2: Refinery Expansion

A refinery expansion project involved integrating new processing units with existing infrastructure. The challenge was to design a piperack system that seamlessly connected the new and existing units while allowing for future expansions. Engineers conducted stress analysis to ensure compatibility between different pipe sizes, optimized support placement, and implemented expansion joints to accommodate thermal movements. The result was a versatile piperack system that not only facilitated the flow of various fluids but also provided a blueprint for future expansion efforts.

Case Study 3: High-Temperature Pipeline

A high-temperature pipeline project required a piperack system capable of handling elevated temperatures and rapid thermal expansions. Engineers opted for advanced materials with excellent high-temperature properties, and the piperack design incorporated expansion loops to absorb thermal movements without imposing undue stress on the pipes and supports. This case highlighted the significance of material selection, stress analysis, and specialized design techniques when dealing with extreme operating conditions.

Conclusion

These case studies exemplify how thoughtful piperack piping designs can address unique challenges and contribute to the success of oil and gas projects. By showcasing innovative solutions, interdisciplinary collaboration, and meticulous planning, these examples underscore the crucial role that piperack systems play in facilitating fluid transport, maintaining safety, and ensuring operational efficiency in diverse industrial scenarios. In the final section, we explore future trends and advancements in piperack piping within the oil and gas industry.

7. Future Trends

As technology and industry practices evolve, so too do the trends and advancements in piperack piping within the oil and gas sector. The future holds exciting possibilities for improving design, efficiency, and sustainability.

Digital Tools and BIM Integration

The integration of Building Information Modeling (BIM) and other digital tools is poised to revolutionize piperack design and visualization. BIM allows for detailed 3D models that encompass not only the physical layout of the piperack system but also data on material properties, stress analysis, and maintenance schedules.

Smart Monitoring and Predictive Maintenance

Advancements in sensor technology and data analytics enable the implementation of smart monitoring systems for piperack piping. Real-time data on factors such as stress levels, temperature, and corrosion rates can facilitate predictive maintenance, preventing failures and minimizing downtime.

Advanced Materials and Coatings

The development of advanced materials and coatings with enhanced resistance to corrosion, high temperatures, and wear is an ongoing trend. These materials can prolong the lifespan of piperack systems and reduce the need for frequent replacements.

Sustainability and Environmental Considerations

The oil and gas industry’s increasing focus on sustainability will likely impact piperack design and operation. Engineers will need to explore environmentally friendly materials, energy-efficient designs, and ways to reduce the carbon footprint of piperack systems.

Conclusion

The future of piperack piping in the oil and gas industry is marked by the integration of digital tools, the implementation of smart monitoring systems, the advancement of materials and coatings, and a heightened emphasis on sustainability. These trends promise to enhance the efficiency, safety, and longevity of piperack systems, aligning with the industry’s evolving needs and priorities. In conclusion, the journey of piperack piping continues to be one of innovation, adaptability, and continuous improvement.

Do not miss the detailed course on Piperack Piping

Enrollment Link

8. Conclusion

Piperack piping stands as a critical component within the oil and gas industry, forming the intricate framework that supports the flow of fluids, utilities, and information throughout facilities. The significance of well-designed piperack systems cannot be overstated, as they contribute to the efficiency, safety, and reliability of operations.

From the careful consideration of piperack layout to the selection of materials, the integration of key components, and the implementation of best practices, every aspect of piperack piping requires thoughtful planning and expertise. Challenges such as harsh environmental conditions, corrosion, dynamic loads, and thermal movements demand innovative solutions and a commitment to compliance with industry standards.

As the industry evolves, so do the tools, materials, and approaches used in piperack design and operation. The integration of digital tools, the rise of smart monitoring systems, and the drive toward sustainability all shape the future of piperack piping. By embracing these trends, engineers can create systems that not only meet the demands of the present but also pave the way for more efficient, resilient, and eco-friendly operations.

In closing, piperack piping exemplifies the intricate balance between engineering prowess and industry needs. Its role in the oil and gas sector continues to evolve, and with each innovation, it contributes to safer operations, improved efficiency, and a more sustainable energy landscape.

FAQs

1. What is the role of piperack piping in an oil and gas facility?

Piperack piping serves as a structural framework that supports, routes, and organizes the network of pipes, utilities, and communication lines within an oil and gas facility. It facilitates the efficient flow of fluids, maintains safety by separating different process lines, and supports equipment and instruments attached to the pipes.

2. How does piperack piping contribute to safety in the industry?

Piperack piping plays a crucial role in maintaining safety by preventing cross-contamination between different types of fluids, which could lead to hazardous reactions. Additionally, the proper design of piperack systems reduces the risk of pipe sagging, vibration-related failures, and potential leaks, enhancing overall operational safety.

3. What challenges are commonly faced when designing piperack piping systems?

Designing piperack piping systems presents challenges such as harsh environmental conditions (corrosion and temperature), dynamic loads caused by vibration and seismic activity, ensuring adequate clearance for maintenance, and addressing the thermal movements of pipes due to temperature changes.

4. How does the integration of digital tools like BIM impact piperack design?

The integration of digital tools like Building Information Modeling (BIM) revolutionizes piperack design by providing detailed 3D models that include information on material properties, stress analysis, and maintenance schedules. This enhances visualization, collaboration between engineering disciplines, and the overall design and planning process.

5. What are some future trends in piperack piping design?

Future trends include the use of smart monitoring systems for real-time data on piperack health, advancements in materials and coatings for durability, integration of sustainability considerations, and the continued use of digital tools like BIM for enhanced design and visualization. These trends aim to make piperack systems more efficient, reliable, and environmentally friendly.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What is a piperack in the context of the oil and gas sector?

Explanation: In the oil and gas sector, a piperack is a structure that provides support for multiple pipelines, helping to organize and route the flow of fluids between various equipment and facilities.

Question 2:

What is the primary function of piperack piping?

Explanation: The primary function of piperack piping is fluid transportation and distribution. It involves carrying various fluids, such as oil, gas, and water, between different processing units and equipment.

Question 3:

What factors are considered when designing piperack piping?

Explanation: When designing piperack piping, factors such as pipe diameter, material, fluid type, pressure, temperature, and safety standards are considered to ensure efficient and safe fluid transportation.

Question 4:

What is the significance of proper pipe routing in piperack design?

Explanation: Proper pipe routing in piperack design is essential to ensure optimal flow rates, avoid clashes with other equipment and structures, and facilitate maintenance and operation. It helps in achieving efficient and safe fluid transportation.

Question 5:

Why is corrosion protection important for piperack piping?

Explanation: Corrosion protection is important for piperack piping to extend the lifespan of pipes, prevent failures due to rust and degradation, and ensure the integrity of the fluid transportation system.