1. Induced Draft Cooling Towers: Fan Location: Induced Draft vs. Forced Draft Cooling Towers

Where is the fan located in induced draft cooling towers?

Explanation: In induced draft cooling towers, the fan is located at the top of the tower, drawing air upwards through the fill media and water spray.

2. Forced Draft Cooling Towers: Water Distribution Challenges

What challenge is associated with water distribution in forced draft cooling towers?

Explanation: Forced draft cooling towers may face challenges in ensuring even water distribution throughout the fill, which can affect performance.

3. Choosing the Right Draft: Energy Efficiency

Which type of cooling tower offers significant energy savings?

Explanation: Induced draft cooling towers offer significant energy savings compared to forced draft towers, requiring 30-75% less energy.

4. Forced Draft Cooling Towers: Noise Levels

Why can fan noise be more noticeable in forced draft cooling towers?

Explanation: Fan noise can be more noticeable in forced draft cooling towers due to the lower fan location, contributing to higher noise levels.

5. Induced Draft Cooling Towers: Advantages

What is an advantage of induced draft cooling towers in terms of air quality?

Explanation: Induced draft cooling towers offer better air quality as drift eliminators effectively remove water droplets from the exiting air stream.

6. Forced Draft Cooling Towers: Installation and Operation

Why are forced draft cooling towers considered ideal for smaller applications?

Explanation: Forced draft cooling towers are considered ideal for smaller applications due to their simpler design, easy installation, and lower initial cost.

7. Choosing the Right Draft: Climate Considerations

Which type of cooling tower may be better in cold climates due to reduced icing risk?

Explanation: Forced draft cooling towers may be better in cold climates due to their lower risk of icing compared to induced draft towers.

Don’t miss the following related topics on Cooling Towers

Short Article on Induced Draft vs. Forced Draft Cooling Towers

Induced Draft vs. Forced Draft Cooling Towers: Understanding the Difference

In the realm of industrial cooling, two main types of mechanical draft cooling towers reign supreme: induced draft and forced draft. Though seemingly similar on the surface, their internal workings and performance characteristics differ significantly, impacting your choice for specific applications.

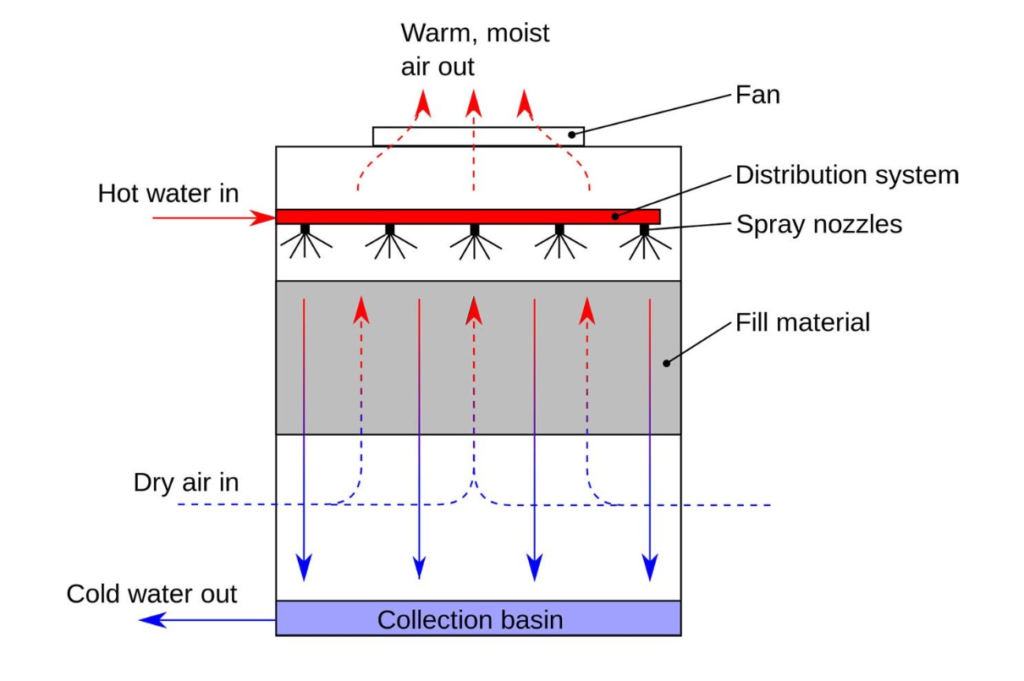

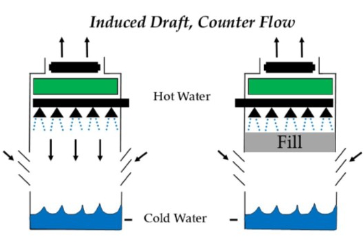

Induced Draft Cooling Towers:

- Fan Location: The fan sits at the top of the tower, drawing air upwards through the fill media and water spray.

- Advantages:

- High efficiency: Achieves optimal cooling performance with less energy consumption (30-75% less than forced draft).

- Reduced recirculation: High exiting air velocities minimize the chance of cooled air being drawn back into the tower.

- Better air quality: Drift eliminators effectively remove water droplets from the exiting air stream.

- Lower noise levels: Compared to forced draft towers.

- Disadvantages:

- Higher initial cost: Due to the elevated fan location and potentially complex design.

- Limited accessibility for maintenance: Reaching the fan at the top can be challenging.

- Susceptible to icing in cold weather: Requires additional protection for the fan and motor.

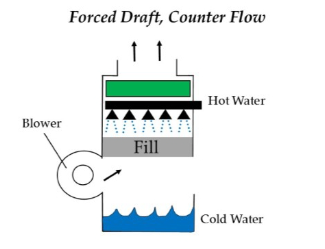

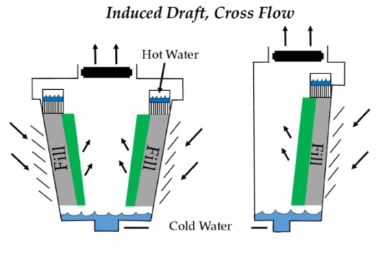

Forced Draft Cooling Towers:

- Fan Location: The fan is located at the base of the tower, pushing air upwards through the fill media and water spray.

- Advantages:

- Lower initial cost: Simpler design and readily accessible fan for maintenance.

- Easy installation and operation: Straightforward design makes them ideal for smaller applications.

- Less susceptible to icing: Fan location reduces the risk of icing compared to induced draft towers.

- Disadvantages:

- Lower efficiency: Less efficient than induced draft towers, requiring higher energy consumption.

- Greater recirculation: Cooled air can be drawn back into the tower, reducing cooling performance.

- Higher noise levels: Fan noise can be more noticeable due to its lower location.

- Water distribution challenges: Ensuring even water distribution throughout the fill can be difficult.

Choosing the Right Draft:

Selecting the best draft type depends on your specific needs and priorities. Consider these factors:

- Required cooling capacity: Induced draft towers are preferred for higher capacity requirements.

- Budget: Forced draft towers are generally cheaper.

- Energy efficiency: Induced draft towers offer significant energy savings.

- Noise sensitivity: Induced draft towers are quieter.

- Maintenance requirements: Forced draft towers offer easier fan access for maintenance.

- Climate: Forced draft towers may be better in cold climates due to reduced icing risk.

Conclusion:

Both induced draft and forced draft cooling towers offer unique benefits and drawbacks. By analyzing your specific needs and priorities, you can confidently choose the draft type that best serves your industrial cooling requirements.tunesharemore_vertadd_photo_alternatemicsend_spark

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.