1. How do mechanical draft cooling towers achieve heat transfer?

Choose the correct statement regarding heat transfer in mechanical draft cooling towers.

Explanation: Heat transfer in mechanical draft cooling towers occurs as water evaporates, cooling the remaining water.

2. What distinguishes Induced Draft cooling towers from Forced Draft cooling towers?

Select the correct feature that distinguishes Induced Draft from Forced Draft cooling towers.

Explanation: The feature that distinguishes Induced Draft from Forced Draft cooling towers is the placement of fans.

3. In which application are mechanical draft cooling towers used to cool hydrocarbons and other process fluids?

Identify the industry application where mechanical draft cooling towers are commonly used.

Explanation: Mechanical draft cooling towers are commonly used in refineries to cool hydrocarbons and other process fluids.

4. What is a potential concern associated with the energy consumption of mechanical draft cooling towers?

Select the correct consideration related to the energy consumption of mechanical draft cooling towers.

Explanation: Mechanical draft cooling towers require more energy due to fan operation, which is a potential concern.

5. What is a benefit of mechanical draft cooling towers compared to natural draft towers?

Identify a specific advantage of mechanical draft cooling towers over natural draft towers.

Explanation: A benefit of mechanical draft cooling towers is their compact design for a smaller footprint compared to natural draft towers.

6. What is the role of fans in mechanical draft cooling towers?

Select the correct statement regarding the role of fans in mechanical draft cooling towers.

Explanation: Fans in mechanical draft cooling towers force air through water droplets to achieve heat transfer.

7. What role do nozzles play in the operation of mechanical draft cooling towers?

Choose the correct statement regarding the role of nozzles in mechanical draft cooling towers.

Explanation: Nozzles in mechanical draft cooling towers spray water into fine droplets, increasing surface area for heat transfer.

Don’t miss the following related topics on Cooling Towers

Short Article on Mechanical draft cooling towers

Mechanical draft cooling towers are the workhorses of industrial cooling, playing a crucial role in maintaining optimal temperatures for various processes. These towering structures, unlike their natural draft counterparts, utilize fans to control the airflow and achieve greater cooling capacity.

How They Work:

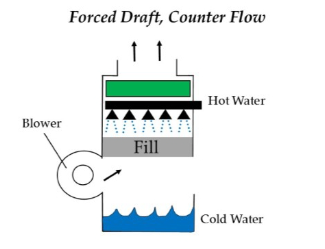

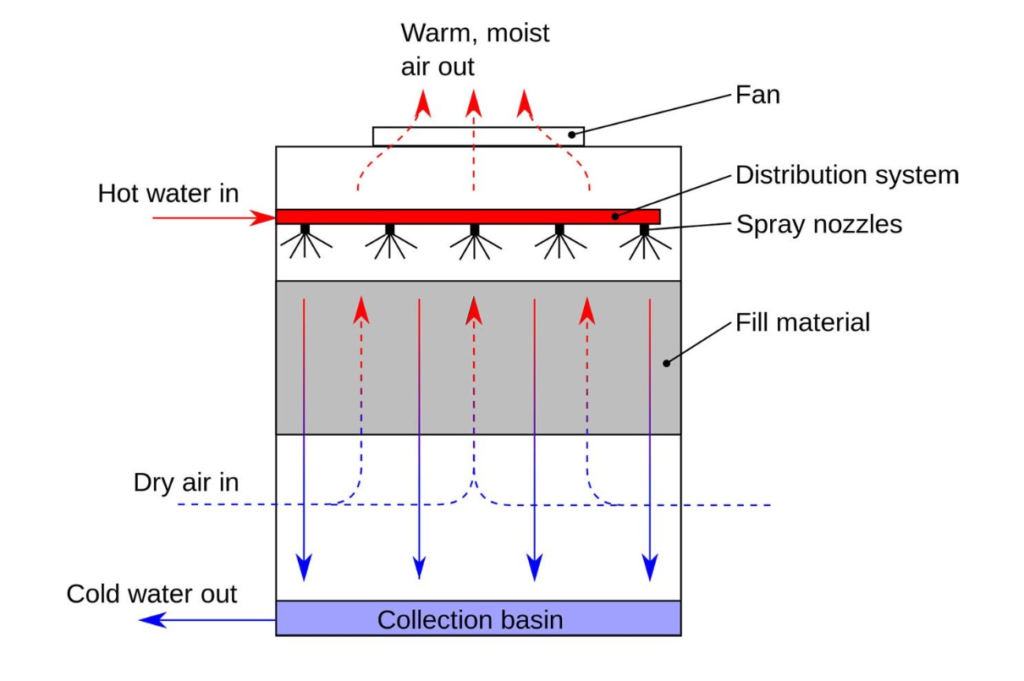

Mechanical draft cooling towers employ a simple yet effective process:

- Hot water from industrial processes enters the tower.

- Nozzles spray the water into fine droplets, increasing surface area for heat transfer.

- Powerful fans, either at the top (induced draft) or bottom (forced draft), force air through the water droplets.

- Heat transfer occurs as the water evaporates, cooling the remaining water.

- Cooled water exits the tower and re-enters the industrial process.

Types of Mechanical Draft Cooling Towers:

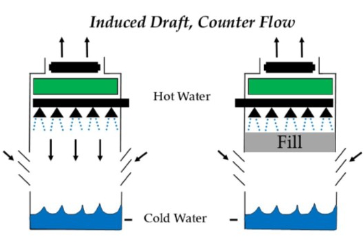

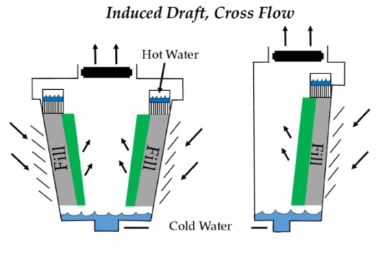

There are two primary types of mechanical draft cooling towers, distinguished by the fan placement:

- Induced Draft: Fans are located at the top of the tower, drawing air upwards through the water spray.

- Forced Draft: Fans are located at the bottom of the tower, pushing air upwards through the water spray.

Each type has its advantages and disadvantages:

| Feature | Induced Draft | Forced Draft |

|---|---|---|

| Cooling Capacity | Higher | Lower |

| Noise Level | Lower | Higher |

| Initial Cost | Higher | Lower |

| Maintenance Requirements | Lower | Higher |

Applications:

Mechanical draft cooling towers are widely used across various industries due to their versatility and efficient cooling:

- Power Plants: They cool water used in steam turbines to generate electricity.

- Chemical Plants: They cool various process fluids and equipment.

- Refineries: They cool down hydrocarbons and other process fluids.

- Manufacturing: They cool machinery and equipment in various manufacturing processes.

- HVAC Systems: They cool water used in large air conditioning systems for buildings.

Benefits of Mechanical Draft Cooling Towers:

- Greater cooling capacity compared to natural draft towers.

- Compact design for smaller footprint.

- Less susceptible to weather conditions.

- Ability to control airflow for optimal cooling performance.

Considerations:

- Energy consumption: Mechanical draft towers require more energy due to fan operation.

- Maintenance: Fans and motors require regular upkeep.

- Noise: Fan noise can be a concern, especially in densely populated areas.

Conclusion:

Mechanical draft cooling towers provide a reliable and efficient solution for industrial cooling needs. Understanding their types, applications, and benefits can help you determine if they are the right choice for your specific requirements.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.