1. What is the primary role of limit stops (Limit Stops vs Pipe Guides) in a piping system?

Choose the correct option:

Explanation: Limit stops act as stern guardians, preventing excessive longitudinal travel of the pipe to ensure stability and protect the system.

2. What is the main function of pipe guides (Limit Stops vs Pipe Guides) in a piping system?

Choose the correct option:

Explanation: Pipe guides act as benevolent guides, ushering in controlled longitudinal movement to ensure the pipe stays on track.

3. What is a key feature of limit stops w.r.t. Limit Stops vs Pipe Guides?

Choose the correct option:

Explanation: Key features of limit stops include acting as restrictive champions against excessive longitudinal travel for stability and protection.

4. What is a key feature of pipe guides?

Choose the correct option:

Explanation: Key features of pipe guides include prioritizing controlled longitudinal movement, maintaining overall alignment, and preventing lateral movement.

5. When should limit stops be used in a piping system?

Choose the correct option:

Explanation: Limit stops should be used when the goal is to prevent excessive longitudinal travel of the pipe and ensure stability.

6. When should pipe guides be used in a piping system?

Choose the correct option:

Explanation: Pipe guides should be used when the goal is to allow controlled longitudinal movement of the pipe, especially when using expansion joints.

7. What is the deciding factor for choosing between limit stops and pipe guides in a piping system?

Choose the correct option:

Explanation: The choice between limit stops and pipe guides depends on the specific needs of the piping system, considering factors such as longitudinal movement requirements, system components, and thermal conditions.

Don’t Miss 20+ Quizzes on Pipe Supports:

Short Article on Limit Stops vs Pipe Guides: Pipe Supports

Limit Stops vs Pipe Guides: Opposing Forces for Controlled Pipe Movement

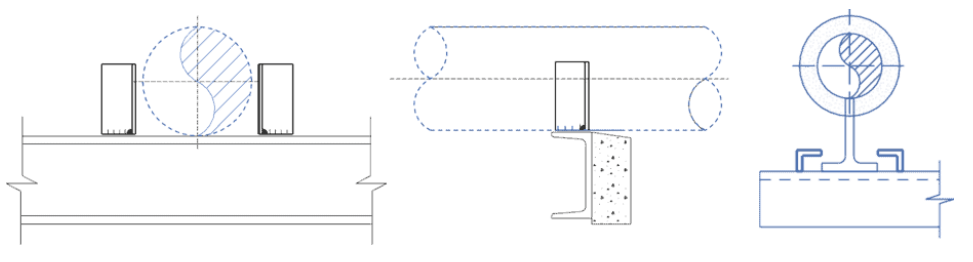

In the intricate world of pipe supports, two seemingly opposing forces play crucial roles in ensuring controlled movement: limit stops and pipe guides. While both deal with pipe movement, their approaches are diametrically different, each serving specific needs within the piping system.

Limit Stops: Guardians Against Excessive Travel

Limit stops act as the stern guardians of the piping system, preventing excessive longitudinal travel of the pipe. Imagine a firm hand saying “No further!” to the pipe’s tendency to expand or contract beyond a predetermined point. This prevents the pipe from overextending and potentially damaging itself, other components, or the surrounding structure.

Key Features of Limit Stops:

- Restrictive champions: Limit stops prioritize stability and restrict movement, acting as a barrier against excessive longitudinal travel.

- Safeguarding pipelines: They are particularly crucial for long pipelines, protecting them from the stresses and strains of significant thermal expansion and contraction.

- Protecting other components: Limit stops prevent the pipe from impacting other components in the system, minimizing the risk of damage and ensuring smooth operation.

- Versatility in design: Limit stops can be designed in various forms, such as brackets, stops bolted to the pipe supports, or even concrete blocks, depending on the specific application and required level of restriction.

Pipe Guides: Ushering in Controlled Movement

In contrast to the restrictive nature of limit stops, pipe guides act as benevolent guides, ushering the pipe along its designated path. They allow for controlled longitudinal movement, ensuring the pipe stays on track and doesn’t deviate from its intended course.

Key Features of Pipe Guides:

- Movement facilitators: Pipe guides prioritize controlled movement, allowing the pipe to expand and contract within a predetermined range without hindering its functionality.

- Expansion joint partners: They work in tandem with expansion joints, ensuring proper alignment and preventing excessive stress on the joint, ultimately extending its lifespan.

- Alignment champions: Pipe guides maintain the overall alignment of the piping system, preventing lateral movement that could lead to misalignment, leaks, and operational issues.

- Diverse applications: They are used in various scenarios, from long pipelines to complex configurations with bends and offsets, ensuring controlled movement throughout the system.

Choosing the Right Tool for the Job

The choice between limit stops and pipe guides depends on the specific needs of the piping system. Here’s a simple guide to help you decide:

- Use limit stops when:

- You need to prevent excessive longitudinal travel of the pipe.

- You have long pipelines with significant thermal expansion and contraction.

- You want to protect other components in the system from potential impact.

- Use pipe guides when:

- You need to allow controlled longitudinal movement of the pipe.

- You are using expansion joints in the system.

- You need to maintain the overall alignment of the piping system.

By understanding the opposing forces of limit stops and pipe guides, you can ensure the smooth and efficient operation of your piping system, safeguarding its integrity and longevity.

Table of Contents

Don’t miss the Course on Effective Isometrics Management: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Complete Course on Piping Engineering

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

- Plant Design & Layouts-OISD 118

- Isometric Management

Library of Technical Articles

Don’t miss out the collection of 15+ articles on following topics:

- Basics of Oil and Gas Industry

- Valves

- Testing

- Tank

- Piping Bulk Items

- Pipe

- Metallurgy

- Piping Materials

- Layout

- Instrumentation

- Heat Exchanger

- Type of Contracts

- Codes and Standards

- ASTM Standards

- Articles on Piping Specialty Items

Video details of Complete Course on Piping Engineering

Why Enroll in the EPCLand

Proven Track Record– PTR

Activities & Achievements before launching EPCLand

- Published more than 50+ short courses

- 3000+ Enrolments

- More than 3,500,00 Minutes of watch hours in the last 2 years

- 4000+ Students in 100+ Countries

- Rating of 4+ out of 5

- 1000+ YouTube Videos

- 8K+ Subscribers

What Students will Learn

- Codes & Standards of the Energy Sector

- Piping Material Engineering

- Piping Layout Engineering

- Stress Analysis

Interesting facts

- All the published courses have been developed by Industry Experts with more than 2 decades of experience

- Content is based on Practical experience and real-time problems.

- Content is designed and organized in such a manner that it can be easily grabbed.

- Complete website, Blogs and Quiz sections are Planned, Designed and published by myself (About me: Atul Singla)

- Complete flexibility of Time & Location, Students can access the content from anywhere & anytime

- Moreover, once enrolled, the content can be access as many times as you want, which helps in understand the fundamentals in a better way.

Conclusion

In conclusion, our courses are meticulously crafted by industry experts with over two decades of hands-on experience. The content is rooted in practical knowledge, addressing real-time problems. The material is thoughtfully designed and organized for easy comprehension. Every aspect, from the website to blogs and quizzes, has been planned, designed, and executed by Atul Singla, ensuring a comprehensive and seamless learning experience. With the flexibility of accessing the content at any time and from any location, students have the freedom to learn on their terms. Furthermore, enrollment grants unlimited access, allowing learners to revisit the material as often as needed, fostering a deep understanding of the fundamentals.