Introduction

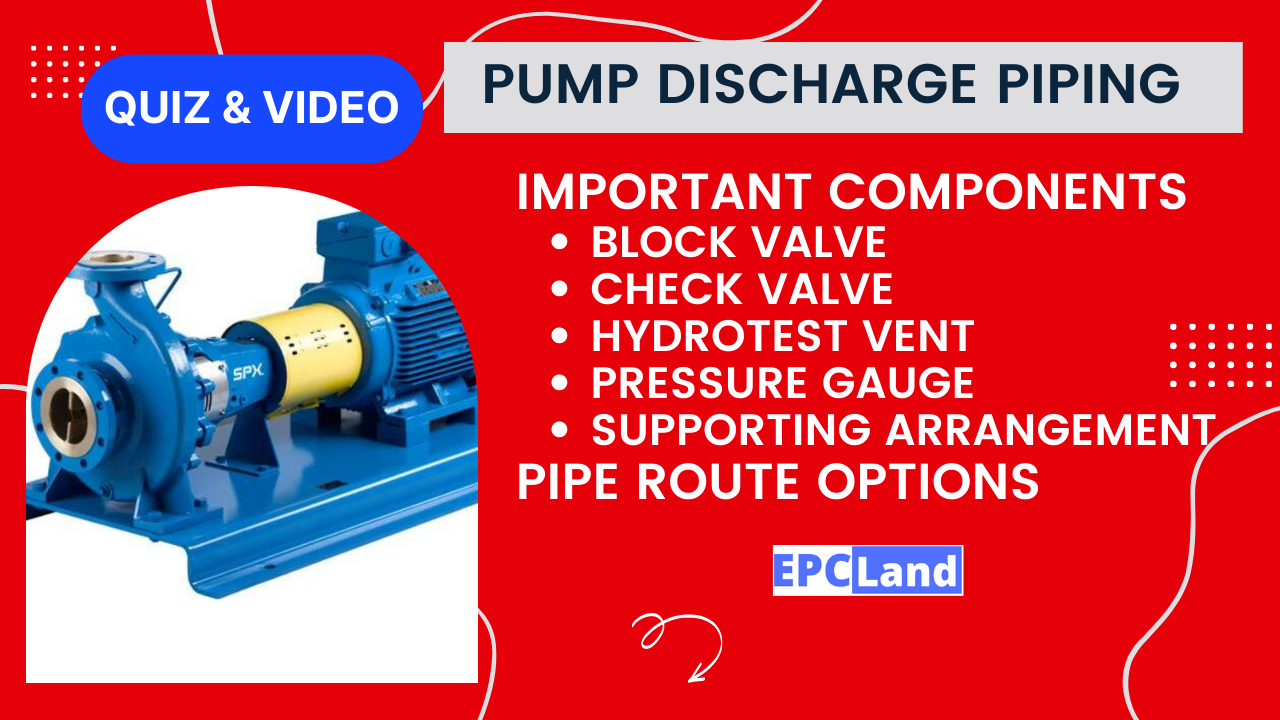

Pump discharge piping plays a pivotal role in various industries, ensuring the safe and efficient transfer of fluids from pumps to their destinations. This intricate system involves several essential components that contribute to the overall functionality and reliability of the process. In this comprehensive guide, we’ll delve into the key components that constitute pump discharge piping and their significance in maintaining seamless operations.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

By EPCLand.com

Block Valve: Control and Isolation

Block valves, often referred to as isolation valves or shut-off valves, are integral components in pump discharge piping. These valves are designed to control the flow of fluids and provide a means to isolate sections of the pipeline for maintenance or emergencies. The ability to halt fluid flow through the pipeline helps prevent unintended fluid release and facilitates efficient maintenance procedures.

Functionality:

- Flow Control: Block valves allow operators to adjust the flow rate of fluids passing through the pipeline, enabling precise control over the process.

- Isolation: During maintenance or emergencies, block valves are closed to isolate the affected section, preventing the spread of fluids and minimizing potential hazards.

Check Valve: Preventing Backflow

A check valve, also known as a non-return valve, is a crucial component in pump discharge piping systems. Its primary function is to prevent backflow of fluids, ensuring that the flow remains unidirectional and preventing the reversal of flow when the pump is turned off.

Functionality:

- Backflow Prevention: Check valves allow fluids to flow in one direction only, preventing the reversal of flow that could damage the pump or compromise the process’s efficiency.

- Pressure Maintenance: These valves help maintain consistent pressure within the system by preventing fluid backflow, ensuring the pump operates optimally.

Hydrotest Vent: Safety and Pressure Release

The hydrotest vent is a safety component often overlooked but critical for pump discharge piping systems. During hydrostatic testing, the vent provides a controlled outlet for the pressurized fluid, preventing over-pressurization and ensuring the integrity of the system.

Functionality:

- Pressure Relief: The hydrotest vent allows excess pressure to escape during testing, preventing potential damage to the system or compromising its structural integrity.

- Safety Assurance: By providing a designated outlet for excess pressure, the hydrotest vent minimizes the risk of accidents or equipment failure during testing procedures.

Pressure Gauge: Monitoring Performance

A pressure gauge is an essential instrument for monitoring the pressure levels within pump discharge piping. It provides real-time data that assists operators in maintaining optimal operating conditions and identifying potential issues.

Functionality:

- Performance Monitoring: Pressure gauges enable operators to monitor the pressure levels at various points within the system, ensuring that the pump is operating within safe and efficient parameters.

- Early Detection: Sudden pressure drops or spikes can indicate issues within the system, enabling timely interventions to prevent further complications.

Supporting Arrangement: Structural Stability

While not a single component, the supporting arrangement of pump discharge piping is vital for ensuring the structural stability and integrity of the entire system. This arrangement includes hangers, supports, and anchor points that prevent undue stress and movement.

Functionality:

- Stress Prevention: Properly placed hangers and supports distribute the weight of the piping, preventing stress concentration that could lead to failure or leaks.

- Alignment Maintenance: Supporting arrangements help maintain the alignment of the piping, ensuring that it remains in the intended position and reducing the risk of mechanical stress.

FAQs:

Q1: Why is a block valve important in pump discharge piping? A1: Block valves enable flow control and isolation, allowing for precise fluid regulation and facilitating maintenance or emergency procedures.

Q2: What is the role of a check valve in pump discharge piping? A2: Check valves prevent backflow, ensuring that fluid flows in one direction only, thus maintaining pump efficiency and preventing damage.

Q3: What is the significance of a hydrotest vent in the system? A3: A hydrotest vent provides a controlled outlet for excess pressure during testing, preventing over-pressurization and ensuring system integrity.

Q4: How does a pressure gauge contribute to pump discharge piping? A4: Pressure gauges monitor real-time pressure levels, assisting operators in maintaining optimal conditions and identifying potential problems.

Q5: Why is a supporting arrangement crucial for pump discharge piping? A5: A proper supporting arrangement ensures the structural stability of the piping, preventing stress concentration and maintaining alignment.

Conclusion

Understanding the key components of pump discharge piping is essential for maintaining efficient and safe operations. Block valves, check valves, hydrotest vents, pressure gauges, and a robust supporting arrangement collectively contribute to the seamless transfer of fluids while minimizing risks and ensuring system longevity. By recognizing the role of each component and their functionalities, industries can optimize their pump discharge piping systems for reliable and effective performance.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What is the function of a block valve in pump discharge piping?

Explanation: A block valve in pump discharge piping is used to control the flow rate of the pumped fluid and isolate the pump from the rest of the system when maintenance or repairs are needed.

Question 2:

What is the purpose of a check valve in pump discharge piping?

Explanation: A check valve in pump discharge piping is designed to prevent reverse flow of fluid back into the pump, ensuring that the pumped fluid only flows in one direction.

Question 3:

What is the purpose of a hydrotest vent in pump discharge piping?

Explanation: A hydrotest vent in pump discharge piping is used to release air from the piping system during hydrostatic testing, ensuring that the system is properly filled with fluid and preventing air pockets that could affect testing results.

Question 4:

What is the role of a pressure gauge in pump discharge piping?

Explanation: A pressure gauge in pump discharge piping is used to measure and display the pressure of the pumped fluid, helping operators monitor and control the system’s performance.

Question 5:

What is the purpose of a supporting arrangement in pump discharge piping?

Explanation: A supporting arrangement in pump discharge piping is designed to prevent vibration, ensure proper alignment, and provide structural support to the piping system, helping to maintain the integrity and stability of the system.