1. Introduction

Gate valves are an essential component of various industrial systems, providing control over the flow of fluids. These valves have a rich history dating back centuries and continue to play a pivotal role in industries such as oil and gas, water treatment, and manufacturing. In this comprehensive guide, we will delve into the world of gate valves, exploring their history, fundamental function, main components, different types, applications, advantages, disadvantages, and the associated codes and standards governing their use.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

2. Brief History

Ancient Beginnings

The concept of controlling fluid flow using a gate-like mechanism dates back to ancient civilizations. Early civilizations, such as the Egyptians and Greeks, developed rudimentary forms of gate valves to manage the flow of water for irrigation and other purposes. These early gate valves consisted of simple wooden or stone gates that could be lowered or raised to control the flow of water in canals and aqueducts.

Industrial Revolution and Modernization

The Industrial Revolution marked a significant turning point in the development of gate valves. During this period, advancements in metallurgy and machining techniques allowed for the production of more robust and reliable gate valves. The introduction of threaded stems and improved sealing materials further enhanced their performance.

Today’s Gate Valves

Modern gate valves are the result of centuries of refinement and engineering innovation. They are manufactured using a variety of materials, including cast iron, bronze, stainless steel, and exotic alloys, depending on the specific application. Gate valves are now found in a wide range of industries, from petrochemical plants to municipal water distribution systems.

3. Basic Function and Working Principle

The Role of Gate Valves

At its core, a gate valve is designed to control the flow of fluids by either allowing or obstructing the passage of the fluid through a pipe or conduit. This function makes gate valves an integral part of many industrial processes where precise flow control is essential.

Working Principle

The working principle of a gate valve is relatively straightforward. It relies on a sliding gate or wedge that can be positioned within the valve body to control the flow of fluid. When the gate is in the fully raised position, the valve is open, allowing fluid to flow freely. Conversely, when the gate is fully lowered, the valve is closed, blocking the flow of fluid.

Actuation Methods

Gate valves can be operated manually or through various automated methods, including handwheels, gears, electric actuators, and pneumatic actuators. The choice of actuation method depends on the application and the need for precision and remote operation.

4. Main Components

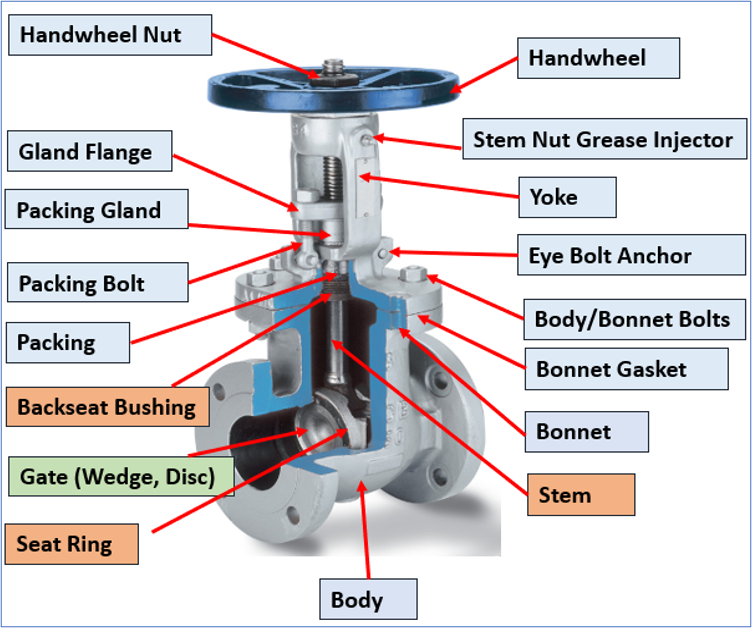

A gate valve consists of several essential components, each playing a crucial role in its operation. Understanding these components is fundamental to comprehending how gate valves work.

Valve Body

The valve body is the main casing that houses all the internal components of the gate valve. It is typically cylindrical or rectangular in shape and is designed to withstand the pressure and temperature conditions of the fluid being handled.

Gate or Wedge

The gate, also known as the wedge, is the central component that controls the flow of fluid. It is typically flat or tapered and is positioned inside the valve body. When the gate is raised, it allows fluid to pass through; when it is lowered, it forms a seal, preventing fluid flow.

Stem

The stem is a threaded rod that connects to the gate and extends outside the valve body. It is used to raise and lower the gate. Manual valves are operated by turning a handwheel attached to the stem, while automated valves use various actuation mechanisms.

Bonnet

The bonnet is a cover that encloses the stem and protects it from external elements. It also provides a means for sealing the valve body.

Seat

The seat is a crucial component that forms a seal around the gate when the valve is closed. It is typically made of a resilient material, such as rubber or Teflon, to ensure a tight seal.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Gland Packing

Gland packing is used to prevent leaks around the stem where it passes through the bonnet. It is usually made of braided materials like graphite or PTFE.

Body Bonnet Joint

The body bonnet joint is the connection between the valve body and the bonnet. Proper sealing at this joint is essential to prevent fluid leakage.

5. Types of Gate Valves

Gate valves come in various types, each designed to meet specific operational requirements. Let’s explore some common types of gate valves and their applications.

Rising Stem vs. Non-Rising Stem

Rising Stem Gate Valves

In rising stem gate valves, the stem moves upward when the valve is opened, providing a visual indicator of the valve’s position. This type is often used in applications where the valve’s status needs to be easily visible.

Non-Rising Stem Gate Valves

Non-rising stem gate valves have a stem that does not move upward when the valve is opened. Instead, the stem is threaded through the gate, and the handwheel or actuator is attached directly to the stem. This design is commonly used in tight spaces or underground installations.

Solid Wedge vs. Flexible Wedge

Solid Wedge Gate Valves

Solid wedge gate valves have a one-piece gate that provides a rigid sealing surface. They are suitable for applications with clean fluids and where a tight shut-off is required.

Flexible Wedge Gate Valves

Flexible wedge gate valves have a gate that is split into segments, allowing it to flex and accommodate variations in temperature and pressure. These valves are often used in applications with changing conditions.

Parallel Slide Gate Valves

Parallel slide gate valves have parallel gate faces that slide against the valve seats. This design minimizes wear and provides tight sealing, making them suitable for high-pressure applications.

Knife Gate Valves

Knife gate valves are designed for handling viscous fluids, slurries, and solids. They have a sharp-edged gate that cuts through the flow medium, making them effective in applications with high solids content.

Wedge Gate Valves

Wedge gate valves feature a wedge-shaped gate that provides a tighter seal as the valve closes. They are commonly used in applications where a secure shut-off is essential.

Through Conduit Gate Valves

Through conduit gate valves have a full-bore design, allowing the passage of pigging devices and other tools. They are often used in the oil and gas industry for pipeline maintenance.

Double Disc Gate Valves

Double disc gate valves have two parallel gates that close in the center, providing bidirectional sealing. They are suitable for applications where flow direction may change.

Slab Gate Valves

Slab gate valves have a flat gate that provides a full-bore opening when fully open. They are commonly used in the oil and gas industry for pipeline applications.

Bonnet Types

Gate valves can have different bonnet types, including bolted bonnets, pressure seal bonnets, and welded bonnets. The choice of bonnet type depends on the pressure and temperature requirements of the application.

6. Applications of Gate Valves

Gate valves find application in a wide range of industries and sectors due to their versatility and ability to provide tight shut-off. Here are some key industries where gate valves are commonly used:

Oil and Gas Industry

In the oil and gas sector, gate valves are used in various applications, including wellheads, pipelines, and refining processes. They are crucial for controlling the flow of crude oil, natural gas, and petroleum products.

Water Treatment and Distribution

Municipal water treatment plants and distribution systems rely on gate valves to control the flow of water. These valves play a vital role in regulating water supply to communities.

Chemical Processing

Gate valves are used in chemical processing plants to control the flow of corrosive and hazardous chemicals. Their ability to provide a tight seal is essential in preventing leaks.

Power Generation

Power plants, both conventional and nuclear, use gate valves to control the flow of steam and coolant in critical systems. These valves ensure the safe and efficient operation of power generation facilities.

Mining

In mining operations, gate valves are employed to handle slurries, tailings, and other abrasive materials. Their robust design makes them suitable for challenging environments.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in commercial and residential buildings use gate valves for regulating the flow of heating or cooling fluids.

Marine and Shipbuilding

Gate valves are used in marine applications to control the flow of seawater, ballast, and other fluids on ships and offshore platforms.

Pharmaceuticals

The pharmaceutical industry relies on gate valves to control the flow of liquids and gases during the production of pharmaceutical products.

Food and Beverage

Gate valves play a role in the food and beverage industry for controlling the flow of liquids and ingredients in manufacturing processes.

Pulp and Paper

In pulp and paper mills, gate valves are used in various stages of the papermaking process, including the control of pulp slurries and chemical additives.

7. Advantages and Disadvantages of Gate Valves

Gate valves offer several advantages and disadvantages, which are important to consider when selecting a valve for a specific application. Here is a table summarizing these key points:

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

| Advantages | Disadvantages |

|---|---|

| Excellent shut-off capability | Slow operation compared to other valve types |

| Low pressure drop | Prone to damage if forced open/closed too quickly |

| Bi-directional sealing capability | Susceptible to wedge and seat wear |

| Suitable for high-temperature applications | Limited throttling capability |

| Minimal fluid turbulence | Can experience “gate sticking” in some cases |

| Versatile and widely used in various industries | Not ideal for applications with high levels of vibration |

8. Associated Codes and Standards

The use of gate valves in various industries is subject to specific codes and standards to ensure safety, reliability, and compliance with industry best practices. Here are some of the prominent codes and standards associated with gate valves:

American Petroleum Institute (API)

The API sets standards for gate valves used in the oil and gas industry. API 600 covers cast steel gate valves, while API 602 covers small forged steel gate valves. These standards specify design, manufacturing, and testing requirements.

American Society of Mechanical Engineers (ASME)

ASME B16.34 provides guidelines for the design, dimensions, and materials of gate valves. ASME B16.5 and ASME B16.47 cover flange dimensions and ratings for gate valves.

International Organization for Standardization (ISO)

ISO 10434 is an international standard that specifies requirements for bolted bonnet steel gate valves for the petroleum and natural gas industries. ISO 15761 provides guidelines for inspection and testing of gate valves.

American Water Works Association (AWWA)

AWWA C509 and AWWA C515 are standards specific to gate valves used in water supply systems. They cover the design, materials, and testing requirements for resilient-seated gate valves.

National Fire Protection Association (NFPA)

NFPA 20, the Standard for the Installation of Stationary Pumps for Fire Protection, includes guidelines for the use of gate valves in fire protection systems.

9. Conclusion

Gate valves have a rich history and continue to be indispensable in various industries. Their ability to provide reliable shut-off, low pressure drop, and versatility in handling different fluids makes them a preferred choice for many applications. As technology continues to advance, gate valves will likely see further improvements in design and materials, ensuring their continued relevance in modern industrial processes.

In this comprehensive guide, we’ve explored the basic function and working principle of gate valves, their main components, different types, applications across industries, and the associated codes and standards that govern their use. Understanding gate valves and their role in fluid control is essential for engineers, technicians, and professionals working in fields where precise flow management is critical.

Whether it’s regulating the flow of oil in a pipeline, ensuring a reliable water supply to a city, or controlling the flow of chemicals in a manufacturing plant, gate valves remain a vital tool for industries worldwide. Their enduring legacy, dating back to ancient civilizations, is a testament to their importance in shaping the course of human progress.

10. FAQs

1. What is the primary function of a gate valve?

- A gate valve is primarily used to control the flow of fluids in a pipeline or conduit. It can either fully open to allow unrestricted flow or fully close to block the flow entirely. This makes gate valves particularly useful for applications that require on/off control rather than flow regulation.

2. What are the advantages of using a gate valve?

- Gate valves offer several advantages, including excellent shut-off capability, minimal pressure drop when fully open, bi-directional sealing, suitability for high-temperature applications, and minimal fluid turbulence. They are also versatile and widely used in various industries.

3. What are the common types of gate valves, and how do they differ?

- Gate valves come in various types, such as rising stem, non-rising stem, solid wedge, flexible wedge, parallel slide, knife gate, and more. These types differ in terms of stem movement, gate design, and application suitability. For example, rising stem gate valves have stems that rise when the valve is opened, while non-rising stem valves do not.

4. What are the key industries that rely on gate valves?

- Gate valves find application in a wide range of industries, including the oil and gas sector, water treatment and distribution, chemical processing, power generation, mining, HVAC systems, marine and shipbuilding, pharmaceuticals, food and beverage, and pulp and paper manufacturing. They are crucial for controlling the flow of fluids in these industries.

5. How can I ensure the proper maintenance of gate valves?

- Proper maintenance of gate valves is essential for their longevity and reliable operation. Regular inspection, lubrication of moving parts, and monitoring for signs of wear or leakage are important steps. Additionally, following manufacturer-recommended maintenance schedules and adhering to industry-specific standards and guidelines are essential for ensuring the safe and efficient operation of gate valves.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Attempt Quiz

Question 1:

What is the primary function of a gate valve?

Explanation: Gate valves are primarily used to start and stop the flow of fluid within a pipeline.

Question 2:

Which type of motion does the gate of a gate valve have?

Explanation: The gate of a gate valve moves in linear motion along the pipeline axis.

Question 3:

Which material is commonly used for making gate valves?

Explanation: Gate valves are commonly made from materials like brass, cast iron, or stainless steel.

Question 4:

What is the advantage of a gate valve over a globe valve?

Explanation: Gate valves generally have a higher pressure handling capacity compared to globe valves.

Question 5:

What is the sealing element in a gate valve?

Explanation: The sealing element in a gate valve is a wedge, which fits into the valve seat to stop the flow.

Question 6:

What is the most common application of gate valves?

Explanation: Gate valves are commonly used in applications such as gas pipelines and fire hydrants.

Question 7:

Which direction should the gate of a gate valve move to open the flow?

Explanation: The gate of a gate valve should move downward to open the flow of fluid.

Question 8:

What is the disadvantage of a gate valve compared to a ball valve?

Explanation: Gate valves have a higher pressure drop compared to ball valves, which is a disadvantage.

Question 9:

What is the purpose of a bypass valve in a gate valve system?

Explanation: A bypass valve in a gate valve system provides an alternate flow path, allowing some fluid to pass through even when the main gate valve is closed.

Question 10:

What is the typical operating mechanism of a gate valve?

Explanation: Gate valves are often operated using a handwheel, allowing manual control of the valve.