Introduction

Storage tanks play a crucial role in various industries by providing a safe and efficient means of storing liquids, ranging from petroleum products to chemicals. Among the diverse types of storage tanks, Internal and External Floating Roof Tanks i.e. IFR & EFR tanks have gained prominence due to their unique designs and benefits. In this article, we will delve into the intricacies of both types of tanks, exploring their components, advantages, limitations, and real-world applications. By comparing their features and discussing their respective pros and cons, we aim to assist industries in making informed decisions when selecting the appropriate storage solution.

Table of Contents

Do not miss the detailed course on Tank Farm Layout & Stress Analysis

Enrollment link

Check out Similar Articles on other Storage Tanks

Internal Floating Roof Tanks (IFR)

Understanding IFR Tanks

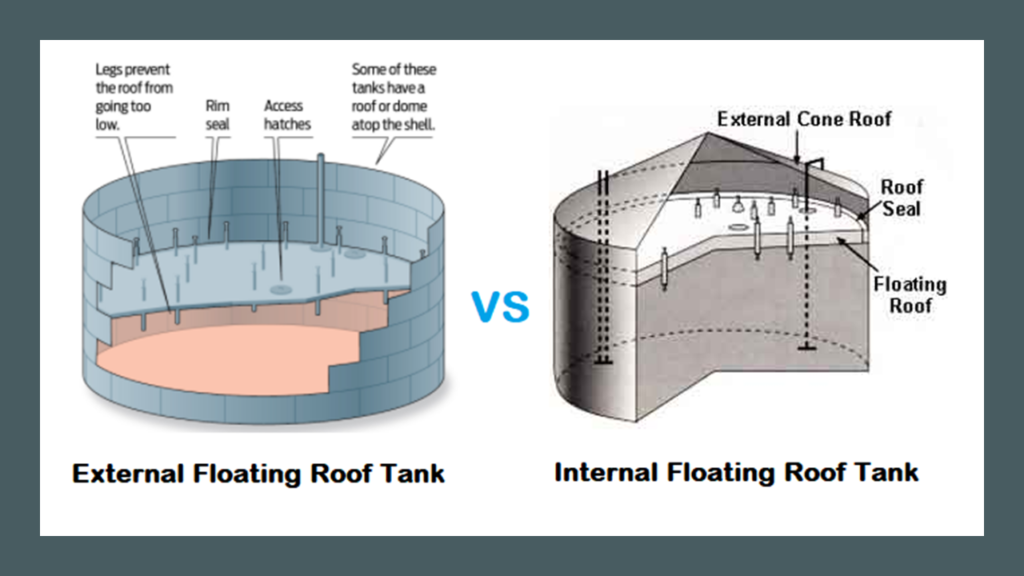

Internal Floating Roof (IFR) tanks are a specialized type of storage tank designed to minimize vapor emissions and reduce product evaporation. Unlike traditional fixed-roof tanks, IFR tanks incorporate a floating roof within the tank, which moves up and down with the liquid level. This design serves to reduce the vapor space within the tank, thus decreasing the chances of emission.

Components and Design

IFR tanks consist of several critical components, including the floating roof itself, the seal system, and the support structure. Floating roofs come in various types, such as pontoon and full-contact roofs. Pontoon roofs are supported by a series of floating compartments, while full-contact roofs maintain direct contact with the stored liquid. The seal system is pivotal in preventing vapor leakage and is often composed of materials like neoprene or elastomer. The support structure ensures the stability of the floating roof and is equipped with guide poles to prevent tilting.

Tank Components

| Component | Description |

|---|---|

| Floating Roof | Moves with liquid level, reduces vapor space |

| Seal System | Prevents vapor leakage, made of elastomers |

| Support Structure | Ensures roof stability, includes guide poles |

Advantages of IFR Tanks

IFR tanks offer several advantages that make them a preferred choice in many industries:

- Emission Control and Environmental Benefits: IFR tanks significantly reduce vapor emissions, contributing to air quality improvement and regulatory compliance.

- Reduced Product Vaporization: By minimizing the vapor space, IFR tanks reduce product evaporation, resulting in cost savings and preserving product quality.

- Protection Against Weather and External Elements: The enclosed nature of IFR tanks shields the stored product from external elements, such as rainwater and debris.

- Improved Fire Safety and Reduced Evaporation Losses: The closed design of IFR tanks reduces the risk of fires and minimizes evaporation losses during emergencies.

Pros & Cons

Pros of IFR Tanks

| Advantages | Description |

|---|---|

| Emission Control and Environmental Benefits | Significant reduction in vapor emissions |

| Reduced Product Vaporization | Minimized product evaporation and quality loss |

| Protection Against External Elements | Shielding from weather and debris |

| Improved Fire Safety | Lower fire risk and reduced evaporation losses |

Cons of IFR Tanks

| Disadvantages | Description |

|---|---|

| Maintenance Challenges | Complex maintenance of floating roof |

| Potential for Product Contamination | Risk of product contamination during operation |

| Initial Installation Costs | Higher upfront costs compared to other tanks |

Limitations of IFR Tanks

While IFR tanks offer notable advantages, they also have certain limitations:

- Maintenance Challenges: Maintenance of IFR tanks can be complex due to the need to inspect and repair the floating roof and seal systems.

- Potential for Product Contamination: The floating roof could come into contact with the stored product, leading to potential contamination risks.

- Initial Installation Costs: The initial costs associated with the design and installation of IFR tanks can be higher compared to other tank types.

Do not miss the detailed course on Tank Farm Layout & Stress Analysis

Enrollment link

External Floating Roof Tanks (EFR)

Understanding EFR Tanks

External Floating Roof (EFR) tanks are characterized by a floating roof located on the exterior of the tank, supported by the liquid within. This design creates a vapor space between the floating roof and the stored product, reducing vapor emissions.

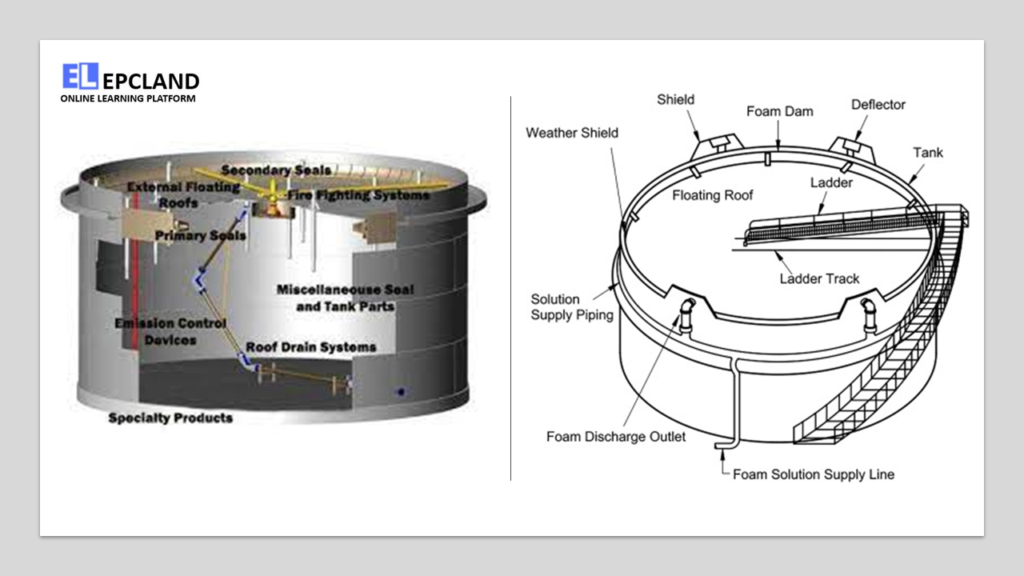

Components and Design

EFR tanks comprise key components that influence their functionality:

- Basic Structure and Rim Seal Systems: EFR tanks feature a basic cylindrical structure and employ rim seal systems to prevent vapor leakage.

- Types of Floating Roofs: EFR tanks can have single-deck or double-deck floating roofs, each offering distinct advantages in terms of vapor control.

Tank Components

| Component | Description |

|---|---|

| Floating Roof | Exterior roof, supported by stored liquid |

| Rim Seal System | Prevents vapor leakage, ensures airtight seal |

| Basic Structure | Cylindrical tank structure |

Advantages of EFR Tanks

EFR tanks offer various advantages that cater to different industry requirements:

- Cost-Effectiveness in Construction: EFR tanks are generally more cost-effective to construct compared to IFR tanks due to their simpler design.

- Minimal Product Evaporation: The vapor space created by the external floating roof reduces product evaporation and preserves product quality.

- Ease of Maintenance and Inspection: EFR tanks have easier access for maintenance and inspection tasks, facilitating upkeep.

- Suitable for Large-Capacity Storage: EFR tanks are particularly well-suited for storing large volumes of liquids.

Pros & Cons

Pros of EFR Tanks

| Advantages | Description |

|---|---|

| Cost-Effectiveness in Construction | Lower construction costs compared to IFR tanks |

| Minimal Product Evaporation | Reduced evaporation losses, preserved quality |

| Ease of Maintenance and Inspection | Accessible for upkeep and inspection tasks |

| Suitable for Large-Capacity Storage | Ideal for storing large volumes of liquids |

Cons of EFR Tanks

| Disadvantages | Description |

|---|---|

| Vapor Emission Concerns | Less effective in controlling vapor emissions |

| Vulnerability to Weather Conditions | Exposed design can affect product quality |

| Fire Hazards and Safety Considerations | Higher fire risk due to open design |

Do not miss the detailed course on Tank Farm Layout & Stress Analysis

Enrollment link

Limitations of EFR Tanks

Despite their benefits, EFR tanks also come with limitations:

- Vapor Emission Concerns: EFR tanks may not control vapor emissions as effectively as IFR tanks, which could lead to regulatory challenges.

- Vulnerability to Weather Conditions: The open design of EFR tanks exposes the stored product to weather elements, potentially impacting product quality.

- Fire Hazards and Safety Considerations: EFR tanks are more susceptible to fire hazards due to the exposed nature of their design.

Comparative Analysis on Internal and External Floating Roof Tanks

In this section, we will compare Internal Floating Roof (IFR) tanks and External Floating Roof (EFR) tanks across various aspects to facilitate decision-making.

Emission Control and Environmental Impact

Vapor Loss Comparison

| Aspect | IFR Tanks | EFR Tanks |

|---|---|---|

| Vapor Emission Reduction | Highly effective | Moderate effectiveness |

| Regulatory Compliance | Often meets stringent standards | May require additional measures |

Safety and Fire Hazard

Fire Risks and Mitigation

| Aspect | IFR Tanks | EFR Tanks |

|---|---|---|

| Fire Risk | Lower due to enclosed design | Higher due to open design |

| Firefighting Challenges | Easier containment and control | More challenging fire response |

Maintenance and Inspection

Ease of Maintenance

| Aspect | IFR Tanks | EFR Tanks |

|---|---|---|

| Maintenance Access | More challenging due to design | Easier access for maintenance |

| Inspection Frequency | Regular inspections needed | Less frequent inspections |

Initial Costs and Lifecycle Economics

Cost Considerations

| Aspect | IFR Tanks | EFR Tanks |

|---|---|---|

| Construction Costs | Higher due to complex design | Lower due to simpler design |

| Long-Term Operational Costs | Lower due to emission control | Higher due to evaporation |

Industry Applications and Case Studies

Oil and Gas Industry

Internal Floating Roof (IFR) and External Floating Roof (EFR) tanks find applications in the oil and gas industry, offering distinct advantages in various scenarios. For instance, in oil refineries, IFR tanks are often preferred due to their emission control capabilities. An illustrative case study involves a major oil refinery that replaced several conventional tanks with IFR tanks, resulting in substantial emissions reduction and compliance with environmental regulations.

Chemical Industry

In the chemical industry, the storage of hazardous materials necessitates a keen focus on safety and environmental impact. While IFR tanks excel in vapor emission control, EFR tanks may find use in scenarios where cost-effectiveness and ease of maintenance are prioritized. A case study involving a chemical storage facility highlights the strategic placement of both IFR and EFR tanks to cater to different product requirements.

Other Industrial Sectors

Apart from the oil and gas and chemical industries, IFR and EFR tanks also serve various other sectors, such as food and beverage, pharmaceuticals, and water treatment. Each industry’s unique requirements influence the choice between the two tank types.

Do not miss the detailed course on Tank Farm Layout & Stress Analysis

Enrollment link

Future Trends and Innovations

As industries continue to evolve, storage tank technologies are also advancing. Emerging trends include the integration of smart monitoring systems to enhance maintenance and improve safety. Environmental sustainability is becoming a driving factor in tank selection, pushing for the adoption of designs that minimize emissions and resource usage. Additionally, innovations in fire suppression systems are expected to mitigate fire risks associated with both tank types.

Accidents in the Past & Lessons Learned

Past incidents involving storage tanks have provided valuable lessons for industries. Accidents, such as leaks, fires, and structural failures, underscore the importance of proper design, maintenance, and emergency response protocols.

Codes & Standards for Internal and External Floating Roof Tanks

Regulatory standards play a vital role in the design, construction, and operation of storage tanks. The selection of tank type should align with industry-specific codes and standards to ensure compliance and safety.

| Regulatory Aspect | Internal Floating Roof (IFR) Tanks | External Floating Roof (EFR) Tanks |

|---|---|---|

| Emission Control Regulations | Compliant with API 650, EPA regulations | May require additional measures for emission control |

| Fire Safety Standards | NFPA 30, API 2000 | NFPA 30, API 2000 |

| Maintenance and Inspection Guidelines | API 653, API 510 | API 653, API 510 |

| Environmental Protection Requirements | EPA regulations, Clean Air Act | May require additional measures for vapor control |

It’s essential for industries to remain updated on the latest codes and standards related to storage tanks to ensure the safe and compliant operation of their facilities.

Comparison with Other Types

While Internal Floating Roof (IFR) tanks and External Floating Roof (EFR) tanks are the focus of this article, it’s important to note that other types of storage tanks, such as fixed-roof tanks and cone-roof tanks, also have their own merits and limitations. Industries must carefully assess their needs and evaluate various tank options to make well-informed decisions.

Conclusion

In the dynamic landscape of storage tanks, the choice between Internal Floating Roof (IFR) tanks and External Floating Roof (EFR) tanks depends on various factors, including emission control needs, safety considerations, maintenance accessibility, and budget constraints. IFR tanks offer superior emission control and enhanced fire safety, making them suitable for industries with stringent environmental regulations. On the other hand, EFR tanks excel in cost-effectiveness and ease of maintenance, making them a viable choice for industries where emission control may not be the primary concern.

Ultimately, a thorough evaluation of industry-specific requirements and a consideration of the discussed pros and cons are essential in selecting the optimal storage tank solution. As technology and industry standards continue to evolve, it’s crucial for industries to stay informed about the latest developments to make informed decisions that align with their operational goals and environmental responsibilities.

Do not miss the detailed course on Tank Farm Layout & Stress Analysis

Enrollment link

FAQs on Internal and External Floating Roof Tanks

Frequently asked questions (FAQs) about Internal Floating Roof (IFR) tanks and External Floating Roof (EFR) tanks:

- What are Internal Floating Roof (IFR) tanks and External Floating Roof (EFR) tanks?

- IFR tanks are storage tanks with a floating roof positioned inside the tank, which moves with the liquid level to minimize vapor emissions and reduce evaporation. EFR tanks have a floating roof outside the tank, creating a vapor space to control emissions.

- What are the key advantages of IFR tanks?

- IFR tanks offer excellent emission control, reduced product vaporization, protection against weather, improved fire safety, and lower evaporation losses during emergencies.

- What benefits do EFR tanks provide?

- EFR tanks are cost-effective in construction, minimize product evaporation, offer easier maintenance and inspection access, and are suitable for large-capacity storage.

- How do I choose between IFR and EFR tanks for my industry?

- Consider factors such as emission control requirements, fire safety concerns, maintenance accessibility, and budget. If emission reduction is crucial, IFR tanks might be preferred; for cost-effectiveness, EFR tanks could be chosen.

- What regulatory standards should I consider for these tank types?

- For IFR and EFR tanks, important standards include API 650 (for design and construction), API 653 (for tank inspection), NFPA 30 (for fire safety), API 510 (for pressure vessel inspection), and relevant EPA regulations for environmental compliance.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Related Video

Attempt Quiz

Question 1:

What is a key difference between Internal Floating Roof Tanks (IFRT) and External Floating Roof Tanks (EFRT)?

Explanation: A key difference between IFRT and EFRT is the location of the roof relative to the liquid surface. IFRT has a roof that rests directly on the stored liquid, while EFRT has a roof that floats on the liquid’s surface.

Question 2:

Which type of tank is generally better at reducing emissions of volatile organic compounds (VOCs)?

Explanation: EFRTs are generally better at reducing emissions of volatile organic compounds (VOCs) due to the tight seal between the external floating roof and the tank shell.

Question 3:

What is one advantage of Internal Floating Roof Tanks (IFRT) over External Floating Roof Tanks (EFRT)?

Explanation: One advantage of IFRT over EFRT is that IFRT generally has easier access for maintenance due to the roof being internal and not exposed to the environment.

Question 4:

Which type of tank is more suitable for storing light liquids such as gasoline?

Explanation: EFRTs are more suitable for storing light liquids such as gasoline because the external floating roof helps to reduce vapor space and emissions.

Question 5:

Which type of tank requires a fixed roof or cone roof structure in addition to the floating roof?

Explanation: An External Floating Roof Tank (EFRT) requires a fixed roof or cone roof structure in addition to the floating roof to provide extra protection and support.