1. Introduction

Ball valves are integral components in various industries, playing a pivotal role in regulating fluid flow. Their versatility, efficiency, and reliability make them indispensable in applications ranging from oil and gas to pharmaceuticals. Understanding the intricate details of ball valves, from their historical evolution to the nuanced types and applications, is essential for engineers, technicians, and enthusiasts alike.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

2. Brief History

The concept of ball valves traces back to ancient civilizations, where rudimentary forms were used to control water flow in aqueducts. However, it was not until the 19th century that significant advancements occurred. In 1967, engineer John Warren coined the term ‘ball valve’ for his innovative valve design, marking a pivotal moment in its evolution.

3. Basic Function and Working Principle

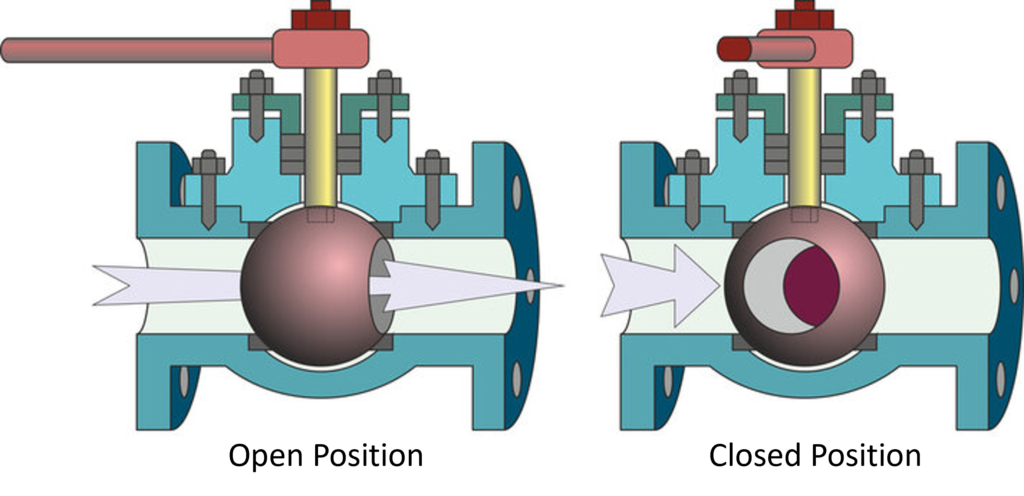

3.1 Fundamental Operation

At its core, a ball valve comprises a spherical closure unit with a through hole. When the hole is aligned with the pipe, fluid flows; when rotated 90 degrees, the flow stops. This simple yet effective mechanism allows for quick and precise control of liquids and gases.

3.2 Role in Regulating Flow and Pressure

Ball valves excel in providing excellent shut-off capabilities, ensuring minimal pressure drop across the valve. Their swift operation makes them ideal for applications where rapid flow control is essential, enhancing efficiency and safety in various systems.

3.3 Comparison with Other Valves

Unlike globe valves, ball valves do not suffer from high pressure drops, making them more energy-efficient. Compared to gate valves, ball valves offer quicker operation, making them advantageous in emergency shut-off situations.

4. Main Components

Understanding the construction of ball valves is crucial for appreciating their functionality.

4.1 Detailed Breakdown

- Body: Usually made of metal, the body houses the components.

- Ball: The spherical closure unit with the flow hole.

- Seats: Elastic materials like PTFE create a watertight seal.

- Stem: Connects the actuator to the ball, facilitating rotation.

- Actuator: A lever, gear, or motor that controls the ball’s position.

4.2 Importance of Materials

Materials like stainless steel, brass, and PVC are commonly used due to their corrosion resistance and durability. The choice of material depends on the specific application and the nature of the fluid being controlled.

5. Types of Ball Valves

Ball valves come in various types, each designed for specific applications.

5.1 Floating Ball Valves

In floating ball valves, the ball is not fixed in place. Instead, it is free to move slightly within the valve body, allowing for a tight seal even with minor misalignments.

5.2 Trunnion-Mounted Ball Valves

Trunnion-mounted ball valves have additional mechanical anchoring of the ball at the top and bottom. This design is ideal for high-pressure applications, providing stability and enhanced sealing.

Advantages and Disadvantages

| Type | Advantages | Disadvantages |

|---|---|---|

| Floating Ball | – Excellent shut-off capabilities | – Limited in high-pressure applications |

| – Minimal pressure drop | – Limited in high-temperature applications | |

| – Quick operation | – Limited in sizes (very large sizes are costly) | |

| – Long service life | – Prone to erosion in abrasive environments | |

| Trunnion-Mounted | – Ideal for high-pressure applications | – Higher cost compared to floating ball valves |

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

6. Applications of Ball Valves

Ball valves find extensive use in diverse industries due to their versatility and reliability.

6.1 Oil and Gas Industry

In the oil and gas sector, ball valves regulate the flow of crude oil, natural gas, and various chemicals. Their ability to function in high-pressure environments ensures the safety and efficiency of drilling and refining processes.

6.2 Water Treatment Plants

Water treatment facilities utilize ball valves to control the flow of water and chemicals. Their quick operation is crucial for managing water distribution, ensuring clean water supply to communities.

6.3 Pharmaceuticals and Biotechnology

Ball valves play a vital role in pharmaceutical manufacturing, where precision and sterility are paramount. They facilitate the controlled transfer of fluids during drug formulation and packaging processes.

7. Relevant Pictures

8. Table for Advantages & Disadvantages

The following table summarizes the advantages and disadvantages of different types of ball valves.

| Type | Advantages | Disadvantages |

|---|---|---|

| Floating Ball | – Excellent shut-off capabilities | – Limited in high-pressure applications |

| – Minimal pressure drop | – Limited in high-temperature applications | |

| – Quick operation | – Limited in sizes (very large sizes are costly) | |

| – Long service life | – Prone to erosion in abrasive environments | |

| Trunnion-Mounted | – Ideal for high-pressure applications | – Higher cost compared to floating ball valves |

9. Table for Associated Codes & Standards

Various standards govern the design and manufacturing of ball valves to ensure their reliability and safety.

| Standard | Description |

|---|---|

| ASME B16.34 | Standard for valve design, manufacturing, and testing |

| API 6D | Specification for pipeline valves |

| ISO 17292 | International standard for ball valves |

| ANSI/FCI 70-2 | Control valve seat leakage classification |

Conclusion

In conclusion, ball valves stand as quintessential components in modern engineering. Their evolution from ancient mechanisms to highly specialized modern designs mirrors the progress of human civilization. Understanding the intricacies of ball valves, from their fundamental operation to the diverse applications across industries, is paramount for engineers and technicians. As technology advances, these valves continue to evolve, ensuring the seamless flow of fluids and gases in various critical processes. Embracing their history, acknowledging their types, and appreciating their applications are essential steps toward harnessing the full potential of ball valves in the 21st century.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

FAQs

1. What is a ball valve and how does it work?

A ball valve is a mechanical device that uses a spherical disc (the ball) to control the flow of liquids and gases through a pipe. When the valve handle is turned, the ball rotates to either block the flow completely or allow it to pass through the pipe. This 90-degree rotation mechanism provides quick and precise control over the fluid flow, making ball valves highly efficient in various applications.

2. What are the advantages of using ball valves over other types of valves?

Ball valves offer several advantages over other types of valves. They provide excellent shut-off capabilities, minimal pressure drop, and quick operation. Unlike globe valves, they do not suffer from high pressure drops, and compared to gate valves, they offer faster operation, making them ideal for emergency shut-off situations. Ball valves are also highly versatile, finding applications in a wide range of industries due to their reliability and efficiency.

3. What are the main components of a ball valve and how do they contribute to its functionality?

The main components of a ball valve include the body, ball, seats, stem, and actuator. The body houses the components, the ball is the spherical closure unit, seats create a watertight seal, the stem connects the actuator to the ball, and the actuator controls the ball’s position. These components work together to regulate the flow of fluids. For example, the ball’s rotation aligns the flow hole with the pipe, allowing fluid to pass, or blocks it, stopping the flow.

4. What are the different types of ball valves and their specific applications?

There are various types of ball valves, including floating ball valves and trunnion-mounted ball valves. Floating ball valves offer excellent shut-off capabilities and are suitable for applications with moderate pressure and temperature. Trunnion-mounted ball valves, on the other hand, are ideal for high-pressure applications due to their enhanced stability and sealing properties. Each type has specific use cases based on factors such as pressure, temperature, and flow requirements.

5. What standards and codes govern the design and manufacturing of ball valves?

Several standards and codes ensure the quality and safety of ball valves. These include ASME B16.34, which covers valve design, manufacturing, and testing standards, API 6D, a specification for pipeline valves, ISO 17292, an international standard for ball valves, and ANSI/FCI 70-2, which classifies control valve seat leakage. Adhering to these standards is crucial for manufacturers to produce reliable and safe ball valves for various industrial applications.

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Attempt Quiz

Question 1:

What is a ball valve?

Explanation: A ball valve is a valve that uses a ball to control fluid flow.

Question 2:

Which industry commonly uses ball valves?

Explanation: The oil and gas industry commonly uses ball valves.

Question 3:

What is the primary advantage of ball valves?

Explanation: Ball valves offer quick quarter-turn operation as their primary advantage.

Question 4:

Which type of fluid is NOT suitable for ball valves?

Explanation: Ball valves are not suitable for highly corrosive chemicals.

Question 5:

What is the ball in a ball valve made of?

Explanation: The ball in a ball valve is typically made of metal.

Question 6:

What does the term ‘full port’ mean in the context of ball valves?

Explanation: ‘Full port’ means the valve has a large ball opening for minimal flow restriction.

Question 7:

Which material is commonly used for the ball in ball valves?

Explanation: Stainless Steel is commonly used for the ball in ball valves.

Question 8:

What is the typical operating mechanism for ball valves?

Explanation: Ball valves can have various operating mechanisms, including Handwheel, Lever, and Gear.

Question 9:

What is the primary function of a ball valve?

Explanation: The primary function of a ball valve is to regulate fluid flow.

Question 10:

Which industry sector commonly uses ball valves for controlling flow?

Explanation: The manufacturing sector commonly uses ball valves for controlling flow.