Introduction

In the complex and highly regulated world of oil and gas exploration and production, every component plays a critical role in ensuring the safe and efficient extraction of hydrocarbons. Among the many specialized components used in the industry, the transition spool piece stands out as a crucial element in the construction and maintenance of wellheads, pipelines, and other critical infrastructure. This article delves into the world of transition spool pieces, exploring their history, functions, types, applications, advantages, and associated industry codes and standards.

Table of Contents

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Brief History

The history of transition spool pieces can be traced back to the early days of the oil and gas industry when the need for standardized connections and efficient flow control became apparent. As drilling techniques advanced and the industry grew, so did the complexity of the infrastructure required to support it. Transition spool pieces emerged as a response to the need for versatile connectors and transition points within the network of pipes, valves, and equipment.

Basic Function and Working Principle

Transition Spool Piece: An Overview

At its core, the basic function of a transition spool piece is to serve as an intermediary component that facilitates the connection between two pipes or equipment with differing specifications. These specifications can vary in terms of size, pressure rating, material, or connection type. Transition spool pieces play a pivotal role in ensuring the seamless integration of various elements within the oil and gas infrastructure, offering the following fundamental functions:

1. Size Transition

One of the primary functions of a transition spool piece is to bridge the gap between pipes or equipment of different sizes. In the oil and gas industry, pipelines, wellheads, and processing equipment often involve pipes with varying diameters. Transition spool pieces are designed to connect these different-sized components, allowing for a smooth transition in the flow path.

2. Pressure Transition

In addition to accommodating size variations, transition spool pieces are engineered to handle differences in pressure ratings. Within an oil or gas system, different components may operate at varying pressure levels. Transition spool pieces ensure that the pressure transition between these components occurs without compromising the safety and integrity of the system.

3. Material Transition

Materials used in the construction of pipelines and equipment can vary, with options including carbon steel, stainless steel, corrosion-resistant alloys, and more. These material differences can create challenges in terms of corrosion, compatibility, and strength. Transition spool pieces enable a seamless connection between components made of different materials, ensuring that there are no compatibility issues or material-related failures.

4. Connection Type Transition

Oil and gas systems often involve components with different connection types, such as flanged, threaded, or welded connections. Transition spool pieces are designed to bridge the gap between these connection types, allowing for secure and leak-free connections between equipment or piping systems.

Working Principle of Transition Spool Pieces

The working principle of a transition spool piece is relatively straightforward, yet it is critical for maintaining the integrity of the oil and gas infrastructure and ensuring efficient fluid flow. Here’s a breakdown of how transition spool pieces work:

- Selection and Design: The selection and design of a transition spool piece depend on the specific requirements of the system it will be integrated into. Factors such as the size, pressure rating, material compatibility, and connection type are considered during the design phase.

- Installation: Once the appropriate transition spool piece is selected and fabricated, it is installed between the two components or sections of the system that require connection. This installation process may involve bolting the spool piece’s flanged ends to the corresponding flanges of the equipment or pipes.

- Sealing Mechanism: Transition spool pieces often incorporate gaskets or sealing materials between the flanges to ensure a leak-free connection. The choice of sealing material depends on the compatibility with the fluid being transported and the environmental conditions.

- Fluid Flow: With the transition spool piece in place, fluid can flow seamlessly from one side to the other. The smooth interior surface of the spool piece minimizes turbulence and pressure drops, optimizing fluid flow efficiency.

- Pressure Equalization: In the case of pressure transition spool pieces, they are designed to distribute and equalize pressure effectively. This prevents pressure surges or imbalances that could potentially damage equipment or compromise safety.

- Material Compatibility: Transition spool pieces designed for material transition ensure that there are no adverse reactions between different materials, preventing corrosion and maintaining the structural integrity of the system.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Types of Transition Spool Pieces

Transition spool pieces come in various types, each designed for specific applications and scenarios. Some common types include:

1. Size Transition Spool Pieces

These spool pieces are used to connect pipes or equipment of different sizes. They are particularly useful when transitioning between wellhead components and pipelines of varying diameters.

2. Pressure Transition Spool Pieces

Pressure transition spool pieces are engineered to accommodate varying pressure ratings within an oil or gas system. They are crucial for maintaining the safety and integrity of the overall system.

3. Material Transition Spool Pieces

When different materials are used in different parts of a system, such as carbon steel, stainless steel, or corrosion-resistant alloys, material transition spool pieces ensure a seamless connection while preventing corrosion or material incompatibility issues.

4. Connection Type Transition Spool Pieces

In situations where equipment or piping systems have different connection types, such as flanged, threaded, or welded, connection type transition spool pieces bridge the gap and ensure a secure fit.

Applications of Transition Spool Pieces

Transition spool pieces find applications throughout the oil and gas industry, and their versatility makes them indispensable in various scenarios:

1. Wellhead Assembly

Transition spool pieces are often used in wellhead assemblies, connecting the wellhead equipment to the production or injection lines. This is critical for ensuring efficient fluid transfer and maintaining wellhead integrity.

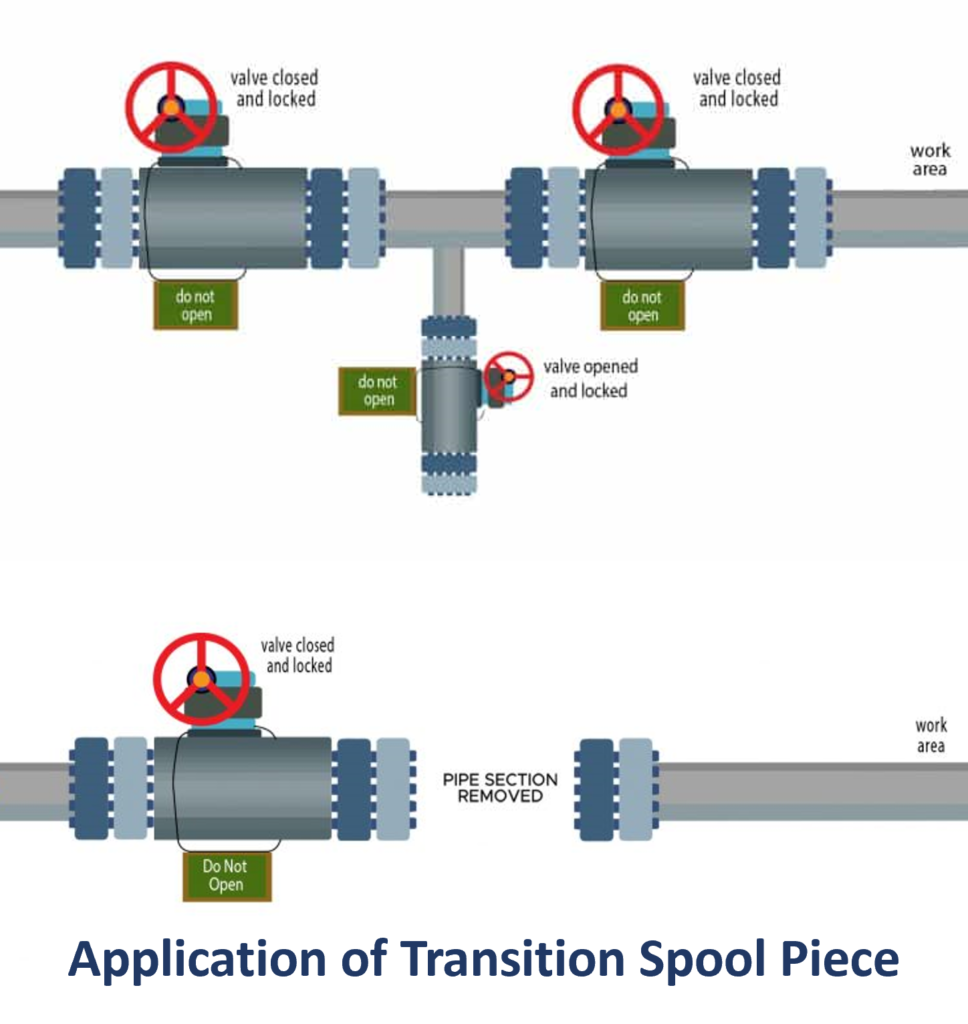

2. Pipeline Construction and Repair

During the construction of pipelines or when repairing existing pipelines, transition spool pieces help connect different sections, sizes, or materials, ensuring a continuous flow path and preventing leaks or disruptions.

3. Pressure Management

In oil and gas processing facilities, pressure transition spool pieces are vital for managing variations in pressure levels between different equipment and systems. They facilitate safe and efficient fluid transfer while mitigating pressure-related risks.

4. Material Compatibility

Transition spool pieces play a crucial role in ensuring compatibility between different materials used in oil and gas operations. This is especially important in corrosive environments or when transitioning from downhole operations to surface facilities.

Advantages & Disadvantages

Transition spool pieces offer several advantages in the oil and gas industry:

Advantages

- Versatility: They can connect pipes and equipment with different specifications, reducing the need for custom-made components.

- Flexibility: Transition spool pieces can be easily integrated into various parts of the infrastructure, allowing for system modifications and expansions.

- Pressure Management: Pressure transition spool pieces help maintain the integrity of the system by handling pressure differentials effectively.

- Material Compatibility: They prevent material-related issues, such as corrosion or incompatibility, by providing a smooth transition between materials.

Disadvantages

- Cost: Transition spool pieces can be expensive, especially when custom fabrication is required.

- Complexity: In some cases, the addition of transition spool pieces can complicate the system design and maintenance.

- Installation Time: Installing transition spool pieces may require downtime, impacting production schedules.

Associated Codes & Standards

The oil and gas industry places a strong emphasis on safety, reliability, and consistency. Therefore, transition spool pieces must adhere to various codes and standards to ensure their proper design, fabrication, and installation. Some of the key industry standards include:

1. ASME B31 Series

The American Society of Mechanical Engineers (ASME) B31 series of codes and standards provides guidelines for the design, construction, and maintenance of piping systems, including those involving transition spool pieces. These standards ensure the safety and reliability of piping systems in the oil and gas industry.

2. API RP 17O

The American Petroleum Institute (API) Recommended Practice 17O focuses on the design, material selection, fabrication, testing, and installation of subsea equipment, including transition spool pieces used in offshore operations.

3. ISO Standards

The International Organization for Standardization (ISO) has developed a range of standards related to pipeline systems and components, including ISO 15590-1, which covers the requirements for transition spool pieces used in onshore and offshore pipeline systems.

Conclusion

Transition spool pieces are unassuming yet vital components in the oil and gas industry. Their ability to seamlessly connect different elements of the infrastructure, accommodate variations in pressure and materials, and comply with industry codes and standards makes them indispensable for ensuring the safe and efficient flow of hydrocarbons. As the industry continues to evolve, the importance of these versatile connectors will only grow, contributing to safer and more reliable operations in the oil and gas sector.

FAQs

1. What is a transition spool piece, and why is it necessary in the oil and gas industry?

- A transition spool piece is a short, cylindrical section of pipe with flanged ends that serves as an intermediary component. It’s necessary in the oil and gas industry to connect different pipes, equipment, or systems with varying sizes, pressure ratings, materials, or connection types. It ensures a smooth transition and maintains the integrity of the overall infrastructure, preventing leaks and disruptions in fluid flow.

2. What are the common types of transition spool pieces used in the industry?

- Transition spool pieces come in various types, including size transition spool pieces, pressure transition spool pieces, material transition spool pieces, and connection type transition spool pieces. Each type is designed for specific applications, such as accommodating different pipe sizes, managing pressure differentials, addressing material compatibility issues, and connecting systems with different connection types.

3. How are transition spool pieces used in wellhead assemblies and pipeline construction?

- In wellhead assemblies, transition spool pieces are used to connect wellhead equipment to production or injection lines, ensuring efficient fluid transfer while maintaining wellhead integrity. In pipeline construction, they play a crucial role in connecting different sections of pipelines, sizes, or materials, ensuring a continuous flow path and preventing leaks or disruptions.

4. What are the advantages and disadvantages of using transition spool pieces in the oil and gas industry?

- Advantages include versatility, flexibility, effective pressure management, and prevention of material compatibility issues. However, disadvantages may include cost, complexity in system design, and potential installation downtime.

5. Which industry codes and standards govern the design and use of transition spool pieces?

- Transition spool pieces in the oil and gas industry must adhere to various industry codes and standards, including the ASME B31 series, API RP 17O, and ISO standards. These standards provide guidelines for the design, material selection, fabrication, testing, and installation of transition spool pieces to ensure safety, reliability, and compliance with industry requirements.

Don’t miss the Complete Course on Piping Engineering: Check Now

Enrollment Link

Recommended courses (Published on EPCLand)

- Basics of Piping Engineering

- Piping Layout Engineering

- Piping Material Engineering

- Piping Stress Analysis

- Complete Course on Piping Engineering

- Material Requisitions

- Piping Material Specifications

- Valve Material Specifications

Don’t miss the published articles on following:

Attempt Quiz

Question 1:

What is the primary function of a Transition Spool Piece in an oil & gas project?

Explanation: A Transition Spool Piece is primarily used to connect different pipeline sizes or types in an oil & gas project.

Question 2:

Which material is commonly used in the construction of Transition Spool Pieces for oil & gas applications?

Explanation: Carbon Steel is commonly used in the construction of Transition Spool Pieces for oil & gas applications due to its strength and durability.

Question 3:

What is the purpose of flanges on a Transition Spool Piece?

Explanation: The purpose of flanges on a Transition Spool Piece is to provide a secure and leak-free connection to other components in the oil & gas system.

Question 4:

What is the typical diameter range of Transition Spool Pieces used in oil & gas projects?

Explanation: Transition Spool Pieces in oil & gas projects typically have a diameter range of 4-12 inches, but they can vary depending on the project requirements.

Question 5:

What is the primary advantage of using a Transition Spool Piece over other methods of pipeline connection?

Explanation: The primary advantage of using a Transition Spool Piece is the flexibility it provides to connect different pipeline sizes and types in an oil & gas project.

Question 6:

What is the maximum pressure rating typically associated with Transition Spool Pieces?

Explanation: The maximum pressure rating of Transition Spool Pieces can vary, but they are often rated for pressures of 1500 psi or higher, depending on the project requirements.

Question 7:

What is the role of gaskets in the installation of Transition Spool Pieces?

Explanation: Gaskets are used to provide a seal between flanges on a Transition Spool Piece, ensuring a leak-free connection in an oil & gas project.

Question 8:

Which industry standard is commonly followed in the manufacturing of Transition Spool Pieces for oil & gas applications?

Explanation: ASME B16.5 is a commonly followed industry standard for the manufacturing of Transition Spool Pieces used in oil & gas applications.

Question 9:

What is the purpose of external coatings on Transition Spool Pieces?

Explanation: External coatings on Transition Spool Pieces are applied to protect against corrosion and environmental factors, ensuring their durability in harsh conditions.

Question 10:

What is the typical lifespan of high-quality Transition Spool Pieces in oil & gas projects?

Explanation: High-quality Transition Spool Pieces in oil & gas projects typically have a lifespan ranging from 15 to 20 years when properly maintained and used under appropriate conditions.